Environment-friendly and shockproof papery packaging film and preparation method thereof

A packaging film, an environmentally friendly technology, applied in the field of paper environmental shockproof packaging film and its preparation, can solve the problems of no blow molding, easy damage, poor toughness, etc., and achieve the effect of strong waterproof performance, beautiful appearance and light weight

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

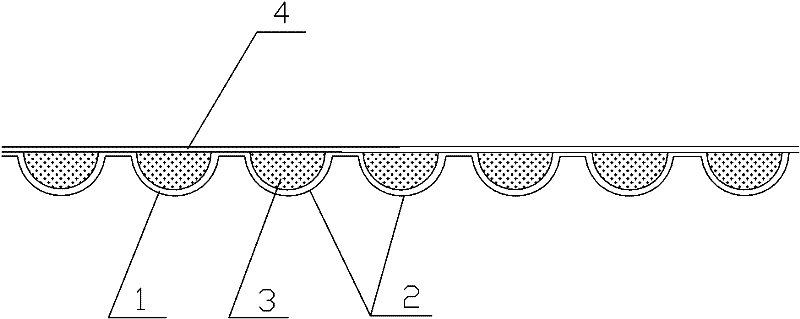

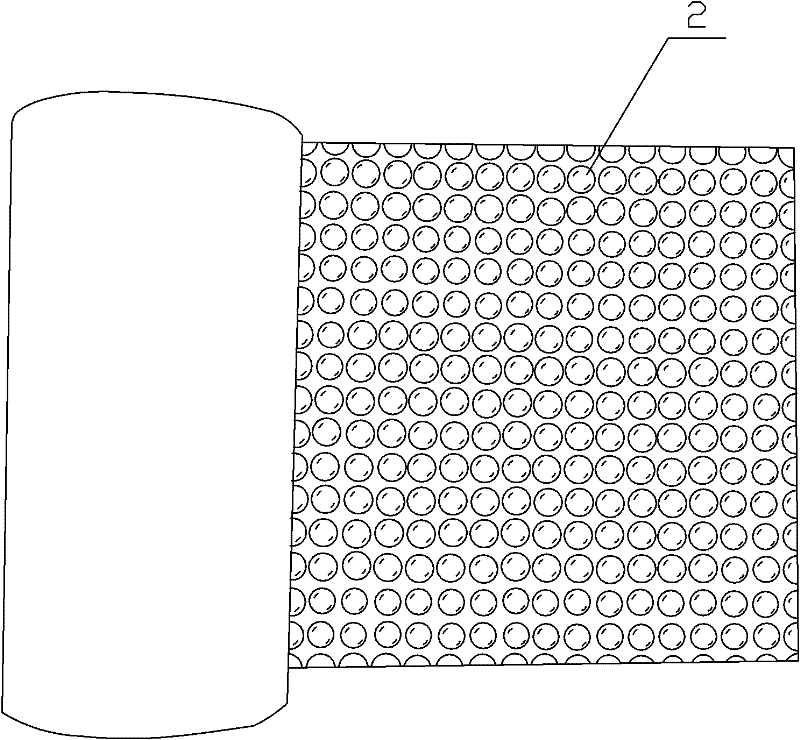

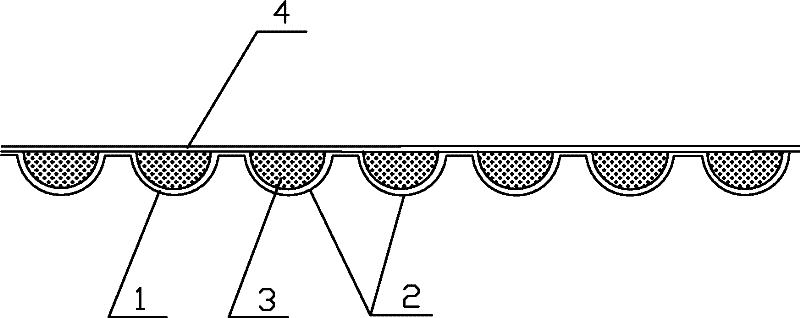

[0035] like figure 1 As shown, the paper environment-friendly shockproof packaging film of the present invention includes a paper film 1 made of plant fibers. The paper film 1 is provided with a number of pits 2, and the pits 2 are filled with pulp 3. Above the pit 1, there are Kraft oil grinding paper film4.

[0036] Add water repellent in kraft oil grinding paper film 4.

[0037] The bark of Chinese wolfberry and the stem bark of hemp japonica are used as raw materials to prepare according to the following steps:

[0038] 1) Peeling the bark: Soak the extremely flexible lycium bark and hemp stem bark in a pool, take them out after 6 days, peel off the black bark and white bark with a knife, and keep the white bark for later use;

[0039] 2) Soaking: Soak the white skin in an aqueous sodium hydroxide solution with a concentration of 10-15%;

[0040] 3) Cooking: cooking for about 72 hours;

[0041] 4) Pulverization: Put the boiled leather material into a pulverizer to pulv...

Embodiment 2

[0048] The difference from Example 1 is that the pulp 3 filled in the pit 2 is made of waste paper.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com