Self-repairing liquid metal flexible electronic material capable of being completely recycled, and preparation method and application thereof

A technology of liquid metal and electronic materials, applied in the direction of bendable cables, liquid conductors, bendable conductors, etc., can solve the problems of liquid metal leakage, irreversible damage of liquid metal and substrate, complex preparation process, etc., and achieve resource reduction Effects of waste and environmental pollution, excellent resistance to mechanical damage, and easy large-scale promotion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0047] Embodiment 1. Preparation of self-healing liquid metal flexible electronic materials and circuits of the present invention

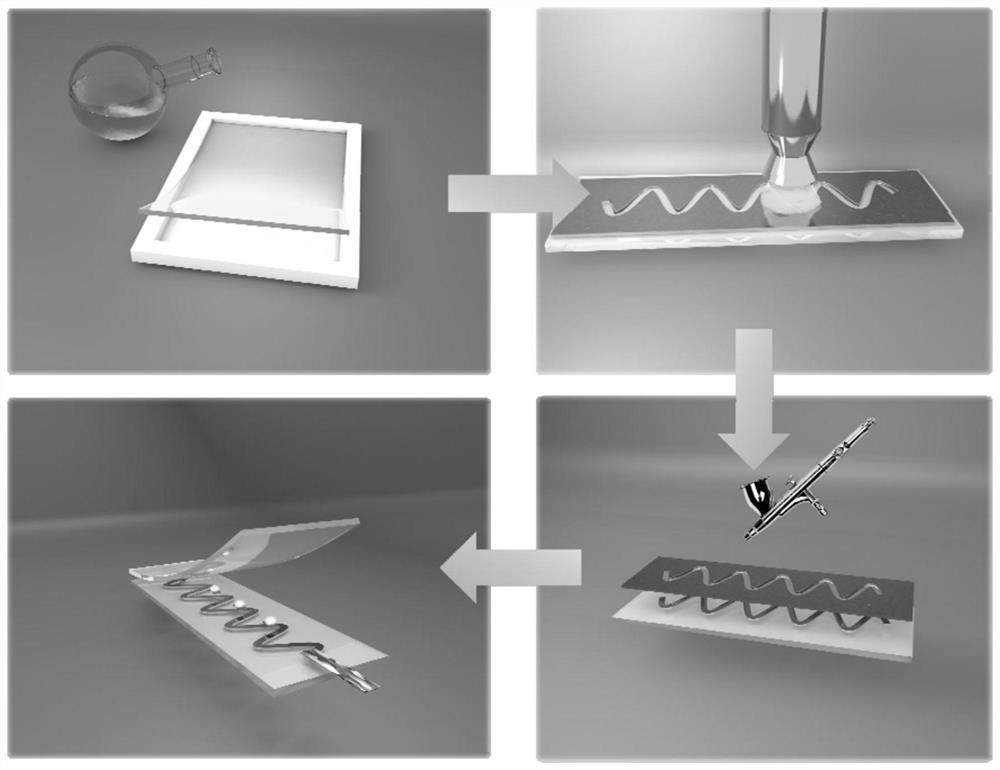

[0048] figure 1 It is the preparation process of the self-repairing liquid metal flexible electronic material and circuit of the present invention.

[0049] (1) Preparation of substrate

[0050] Put 30g of α-lipoic acid, 10g of butyl acrylate, and 10g of acrylic acid into a 250ml round-bottom flask and stir at 150°C to melt completely. After reacting for 3.5h, introduce it into a polytetrafluoroethylene mold and cool to form a transparent polymer substrate.

[0051] (2) Plasma treatment of substrates

[0052]Use computer-aided design according to the required circuit, process the metal template of the designed shape, use the metal template to selectively cover the polymer substrate, and use plasma to perform plasma treatment on the exposed part of the substrate. The gas flow rate during plasma treatment is 30L / min, the plasma power is 500W.

...

Embodiment 2

[0058] Embodiment 2, the preparation of self-healing liquid metal flexible electronic material and circuit of the present invention

[0059] (1) Preparation of substrate

[0060] Put 30g of α-lipoic acid, 10g of acrylic acid, and 10g of isooctyl acrylate into a 250ml round-bottomed flask and stir at 150°C to melt completely. After reacting for 3.5 hours, introduce it into a polytetrafluoroethylene mold and cool to form a transparent polymer substrate. .

[0061] (2) Plasma treatment of substrates

[0062] Use computer-aided design according to the required circuit, process the metal template of the designed shape, use the metal template to selectively cover the polymer substrate, and use plasma to perform plasma treatment on the exposed part of the substrate. The gas flow rate during plasma treatment is 30L / min, the plasma power is 500W.

[0063] (3) Coating liquid metal

[0064] Use an art spray pen to evenly coat a layer of liquid metal on the surface of the treated sub...

Embodiment 3

[0069] Embodiment 3, the preparation of self-healing liquid metal flexible electronic material and circuit of the present invention

[0070] (1) Preparation of substrate

[0071] Put 30g of α-lipoic acid, 10g of butyl acrylate, and 10g of acrylamide into a 250ml round-bottomed flask and stir at 150°C to melt completely. After reacting for 3.5 hours, introduce it into a polytetrafluoroethylene mold and cool to form a transparent polymer substrate. .

[0072] (2) Plasma treatment of substrates

[0073] Use computer-aided design according to the required circuit, process the metal template of the designed shape, use the metal template to selectively cover the polymer substrate, and use plasma to perform plasma treatment on the exposed part of the substrate. The gas flow rate during plasma treatment is 30L / min, the plasma power is 500W.

[0074] (3) Coating liquid metal

[0075] Use an art spray pen to evenly coat a layer of liquid metal on the surface of the treated substrat...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com