A polymer composite material with high gas and liquid barrier performance and its preparation method

A composite material, polymer technology, applied in the direction of coating, can solve the problem of insufficient resistance to mechanical damage and so on

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

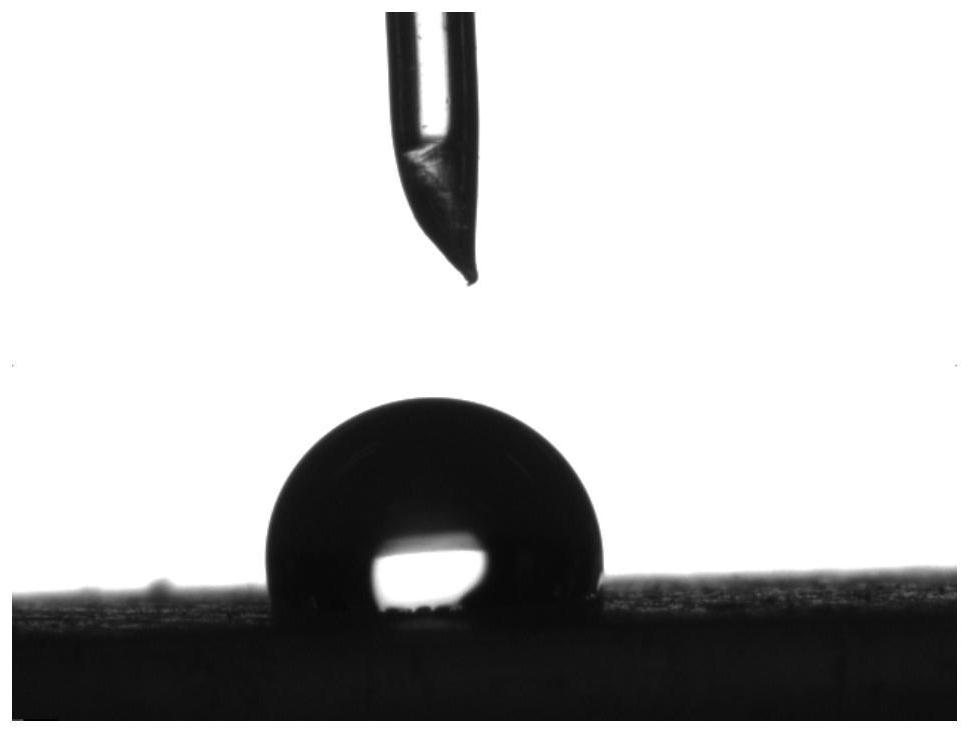

[0064] polymer composite

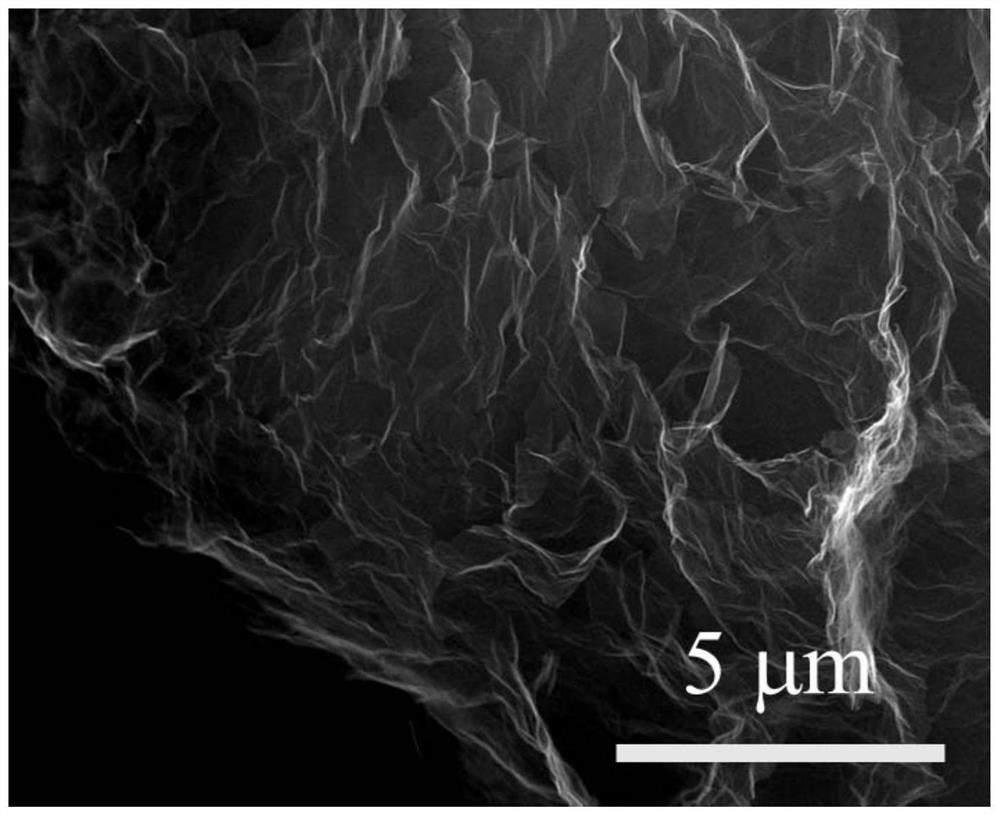

[0065] The polymer composite includes a polymer substrate layer composed of polyethylene terephthalate. Polyacrylic acid with a molecular weight of 5000-50000g / mol chemically grafted on the substrate layer by superthermal hydrogen treatment is used as a modification layer, and a composite coating of graphene oxide and silicone rubber polymer is combined on the outermost surface of the composite material as a barrier function layer. Wherein, the diameter of the graphene oxide sheet is 5-15 microns, and the number of layers is 2-5 layers.

Embodiment 2

[0067] polymer composite

[0068] The polymer composite includes a polymer substrate layer composed of polychlorinated p-xylylene. Polyethylene glycol with a molecular weight of 10,000 to 100,000 g / mol chemically grafted on the substrate layer by superthermal hydrogen treatment is used as a modification layer, and a composite coating of graphene oxide and silicone rubber polymer is combined on the outermost surface of the composite material as a Barrier functional layer. Wherein, the diameter of the graphene oxide sheet is 1-40 microns, and the number of layers is 1-10 layers.

Embodiment 3

[0070] Preparation of polymer composites

[0071] Step (1) Pretreatment of the polymer substrate layer. The polyethylene film was soaked in ethanol for 60min, then dried at 90°C for 10min; then soaked in deionized water for 10min, then dried at 90°C for 10min; then treated with low-temperature plasma for 10s.

[0072] Step (2) Coating and grafting treatment of the modification layer. Polyacrylic acid (the second polymer) with a molecular weight of 2000 g / mol was dissolved in water to prepare a modification layer raw material solution with a mass concentration of 8.5%, and it was dispersed by ultrasonic wave for 10 minutes. Then, the dispersion was coated on the polyethylene substrate layer pretreated in step (1) by dip coating for 3600s, then dried at 50°C for 10min, and then heated in a superheated vacuum with a voltage of 100V and a vacuum of 0.05Pa. After processing in hydrogen equipment for 100s, take it out for use.

[0073] Step (3) Preparation of the barrier functi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| molecular weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com