A Method of Eliminating the Backlash of Dual Drive Mechanism by Using Tension Control

A tension control and tension technology, used in automatic control devices, manufacturing tools, metal processing machinery parts, etc., can solve the problems of measurement error, low backlash elimination efficiency, etc., to eliminate backlash, precise motion control, and ensure processing. The effect of precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

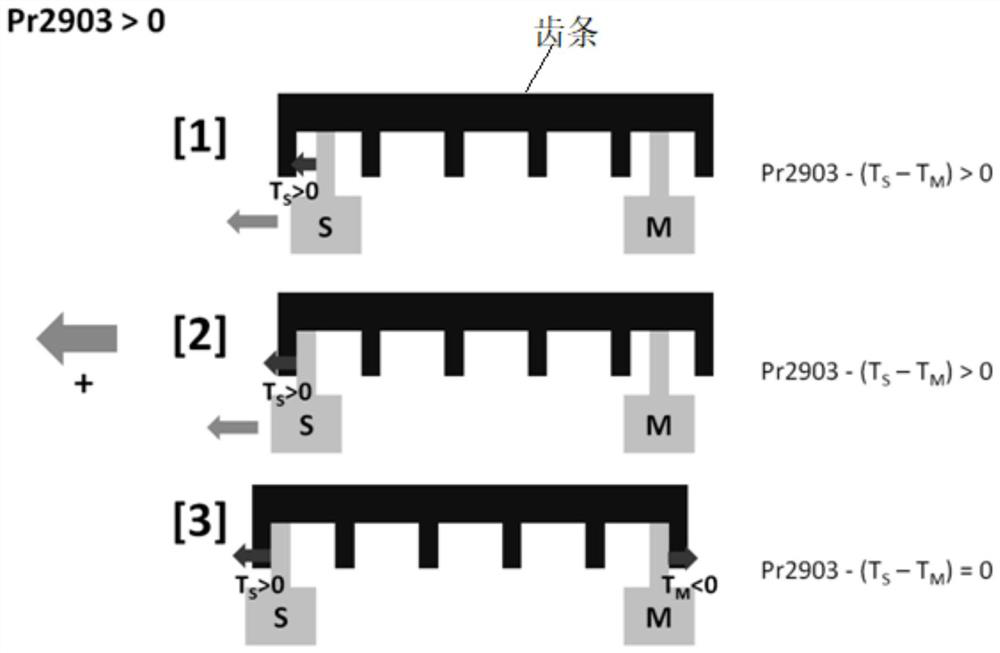

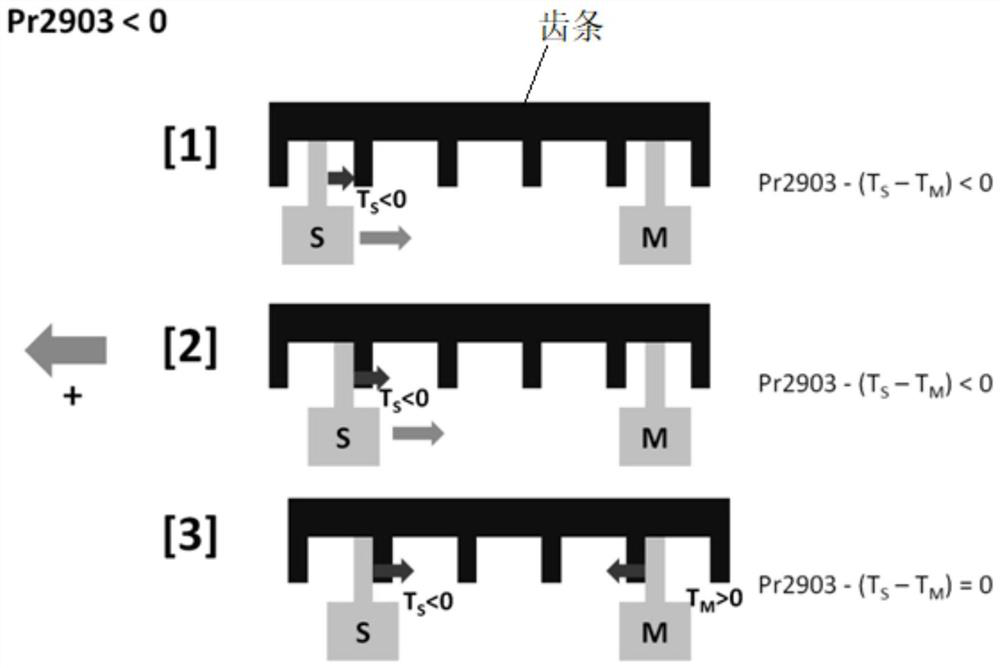

[0021]This embodiment is a method of using a tension control to eliminate a double-drive mechanism, which includes the following steps:

[0022]1) Provide a control system including a controller, a first driving member controlled by the controller, and the first drive member drives the same load, the second drive. A pair of racks are provided on the load, wherein one rack is engaged with gear engagement of the gear on the active shaft of the first driving member, and the other rack is engaged with the gear of the slave of the second drive member output shaft. transmission;

[0023]2) Set the tension value PR2903 in the controller;

[0024]3) First initiate the second drive to control the driven shaft in accordance with the preset speed, and the axial load rate of the slave axis of the second drive of the controller real-time and the axial load rate of the first driven When the difference between the two is equal to the setting tension value PR2903, stop the second drive, i.e., the tension co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com