Tool setting device for rotary tool rest of numerically controlled lathe and method

A technology of rotary tool post and CNC lathe, which is applied in the direction of automatic control device, feeding device, metal processing equipment, etc., can solve the problems that cannot meet the requirements of high-precision processing, cannot meet the requirements of processing accuracy, and accuracy errors, etc., and achieve simple structure, Renovation cost is low and the effect of cost reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

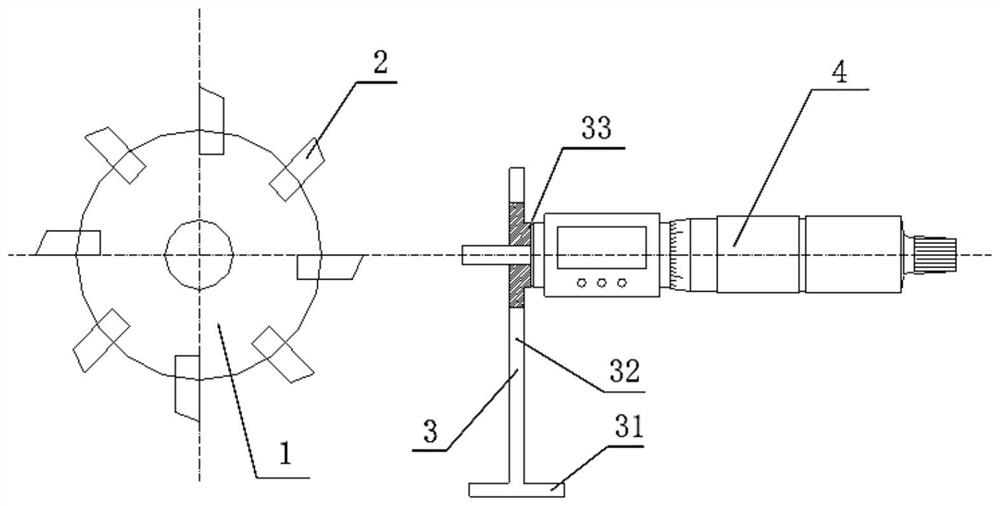

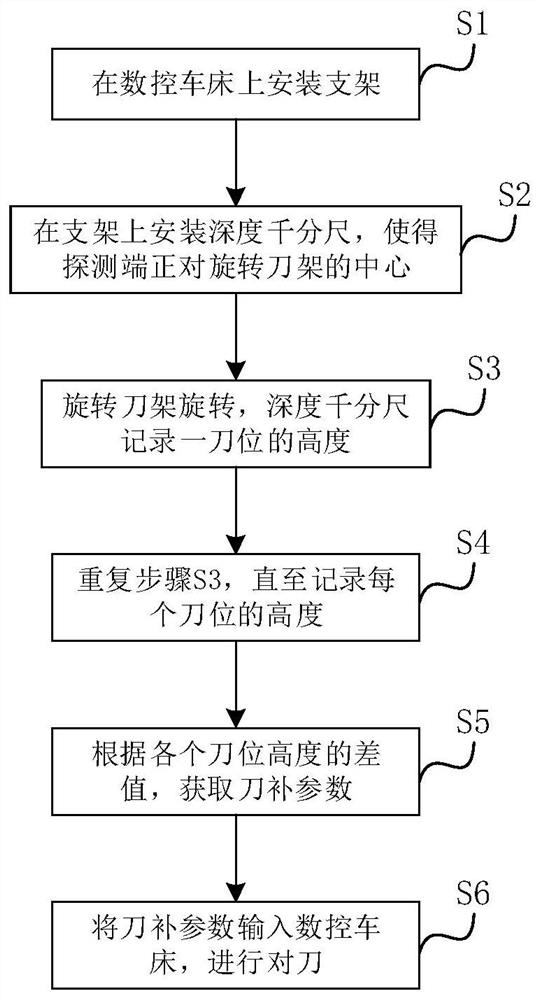

[0045] Such as figure 1 As shown, the present embodiment provides a tool setting device for a rotary tool rest of a CNC lathe, which is used for tool setting of a rotary tool rest 1 on a CNC lathe. The tool setting device includes a bracket 3 and a depth micrometer, and the bracket 3 is installed on the CNC lathe. On the top, the detection end of the depth micrometer is fixed and supported by the bracket 3, and is facing the center of the rotary tool holder, and is used to measure the height of each knife 2 of the rotary tool holder;

[0046] The support 3 includes a base 31 and a support rod 32, the base 31 is fixedly connected to the numerically controlled lathe, the support rod 32 is provided with a connecting hole, the wall of the connecting hole of the support rod 32 is provided with a locking member, and the connecting hole extends into the detection end of the depth micrometer. The locking piece is used to fix the detection end of the depth micrometer;

[0047] Install...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com