A water-repellent and warm-keeping floc and its preparation method

A flake and water-repellent finishing technology, applied in rayon manufacturing, hollow filament manufacturing, and liquid repellent fibers, etc., can solve the problems of difficult processing, serious static problems, limited water-repellent effect, etc. The effect of good water resistance and high warmth retention

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

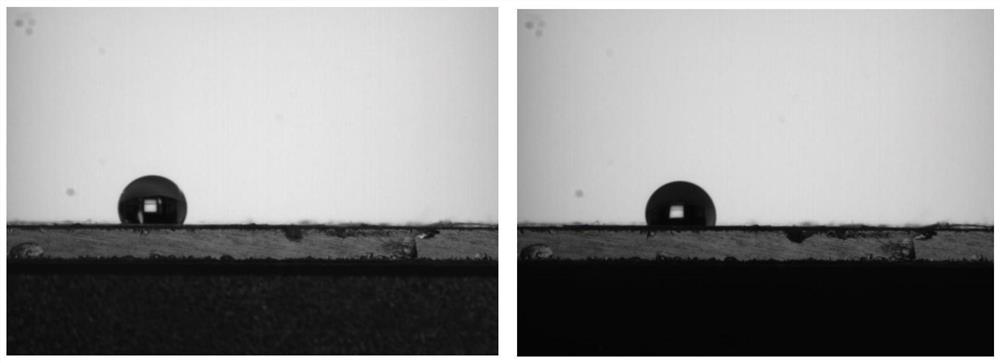

Image

Examples

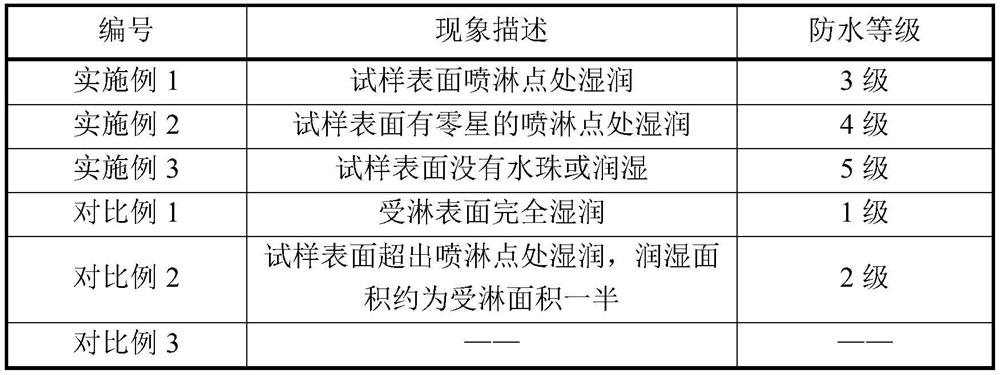

Embodiment 1

[0074] 1. Preparation of fiber nano water-repellent finishing agent: add 1% of KH-570 silane coupling agent (relative to the mass percentage of silicon dioxide) in the ethanol solution to treat nano-zinc dioxide (particle diameter 200nm) and nano-titanium dioxide (particle size) respectively. diameter of 200nm) for surface water-repellent modification, drying and grinding. Add 1% of nano-zinc dioxide and 1% of nano-titanium dioxide (particle size 200nm) modified by surface water repellency into 40% of propyltrimethoxysilane, mix well, and then add D40 solvent to make up the balance.

[0075] 2. Water-repellent finishing of thick-diameter fibers: Soak elastic fibers, hollow polyester fibers (3.33dtex), hollow polyester fibers (6.64dtex), and low-melting-point bonding fibers in fiber nano-water-repellent finishing agents for 20 minutes, then dry A water-repellent thick-diameter fiber was obtained.

[0076] 3. Preparation of thermal wadding: the fiber content and mass percentage...

Embodiment 2

[0080] 1. Preparation of fiber nano water-repellent finishing agent: add 1% of KH-570 silane coupling agent to the ethanol solution to modify the surface of nano-zinc dioxide (particle size 150nm) and nano-titanium dioxide (particle size 150nm), respectively, Dried and ground. Add 1% of nano-zinc dioxide and 2% of nano-titanium dioxide modified by surface water repellency to 45% of octyltrimethoxysilane, mix well, and then add D60 to supplement the balance.

[0081] 2. Water-repellent finishing of large-diameter fibers: soak elastic fibers, hollow polyester fibers, and low-melting-point bonding fibers in fiber nano-water-repellent finishing agents for 20 minutes, and dry to obtain water-repellent large-diameter fibers.

[0082] 3. Preparation of thermal wadding: the fiber content and mass percentage of thermal wadding are composed of: 20% water-repellent elastic fiber, 12.5% water-repellent hollow polyester fiber (3.33dtex), 12.5% water-repellent hollow polyester fiber (6....

Embodiment 3

[0086] 1. Preparation of fiber nano water-repellent finishing agent: Add 1% of KH-570 silane coupling agent to the ethanol solution to modify the surface of nano-zinc dioxide (particle size 50nm) and nano-titanium dioxide (particle size 50nm), respectively, Dried and ground. Add 2% of nano-zinc dioxide and 1% of nano-titanium dioxide modified by surface water repellency to 50% of octyltriethoxysilane, mix well, and then add D70 to supplement the balance.

[0087] 2. Water-repellent finishing of thick-diameter fibers: Soak elastic fibers, hollow polyester fibers, and low-melting-point bonding fibers in fiber nano-water-repellent finishing agents for 20 minutes, and dry them for later use.

[0088] 3. Preparation of thermal wadding: the fiber content and mass percentage of thermal wadding are composed of: 30% water-repellent elastic fiber, 7.5% water-repellent hollow polyester fiber (3.33dtex), 7.5% water-repellent hollow polyester fiber (6.64dtex) , water-repellent low-melting...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com