A kind of instant noodle cup lid coated paper and preparation process thereof

A technology of cup lid coated paper and instant noodles, which is applied in the field of composite paper, can solve the problems of similar compatibility, peeling production, and micro-effectiveness, etc., and achieve the effects of improving adhesion performance, good transparency, and enhancing adhesive strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0041]Embodiment 1 discloses a kind of instant noodle cup lid coated paper of the present invention and its preparation process,

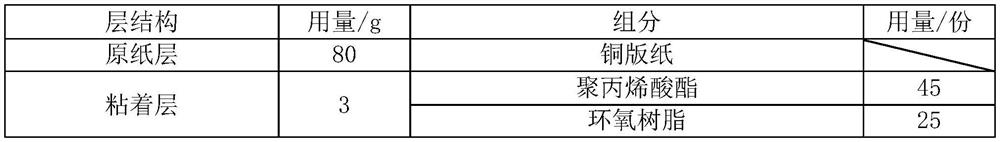

[0042] The layer structure, components and dosage of instant noodle cup lid coated paper are shown in the table below:

[0043]

[0044] The preparation method of modified low-density polyethylene is as follows: 1) Use methylamine to spread the distance between zirconium phosphate layers, and then intercalate dodecyl dimethyl benzyl ammonium chloride into zirconium phosphate molecules to obtain dodecyl dimethyl benzyl ammonium chloride. Alkyl dimethyl benzyl ammonium chloride is intercalated with zirconium phosphate; 2) Heat the low-density polyethylene to a molten state, then add polyurethane to the molten low-density polyethylene, and after the two are evenly mixed, add dodecyl Dimethyl benzyl ammonium chloride is intercalated with zirconium phosphate, and the three are mixed uniformly to obtain a blend; 3) after the blend is extruded, granula...

Embodiment 2

[0056] Embodiment 2 discloses a kind of instant noodle cup lid coated paper of the present invention and its preparation process,

[0057] The layer structure, components and dosage of instant noodle cup lid coated paper are shown in the table below:

[0058]

[0059]

[0060] The preparation method of modified low-density polyethylene is as follows: 1) use methylamine to expand the distance between zirconium phosphate layers, and then intercalate hexadecyltrimethylammonium bromide into zirconium phosphate molecules to obtain hexadecyl trimethylammonium bromide. Trimethyl ammonium bromide intercalated zirconium phosphate; 2) Heat the low-density polyethylene to a molten state, then add polyurethane to the molten low-density polyethylene, and after the two are evenly mixed, add hexadecyl trimethyl bromide Ammonium chloride intercalated zirconium phosphate, and after the three were mixed evenly, a blend was obtained; 3) after the blend was extruded, granulated, and sieved,...

Embodiment 3

[0062] Embodiment 3 discloses a kind of instant noodle cup lid coated paper of the present invention and its preparation process,

[0063] The layer structure, components and dosage of instant noodle cup lid coated paper are shown in the table below:

[0064]

[0065] The preparation method of modified low-density polyethylene is with embodiment 1;

[0066] The preparation process of the coated paper for the cup lid of instant noodles is the same as in Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com