Parapet wall connecting structure and construction method thereof

A technology for connecting structures and parapets, applied to building structures, snow traps, roof insulation materials, etc., can solve the problems of long construction period, reduced construction efficiency of construction personnel, and many processes, so as to improve construction efficiency and facilitate fixing methods Simple, life-extending effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0041] The present invention will be described in further detail below in conjunction with the accompanying drawings.

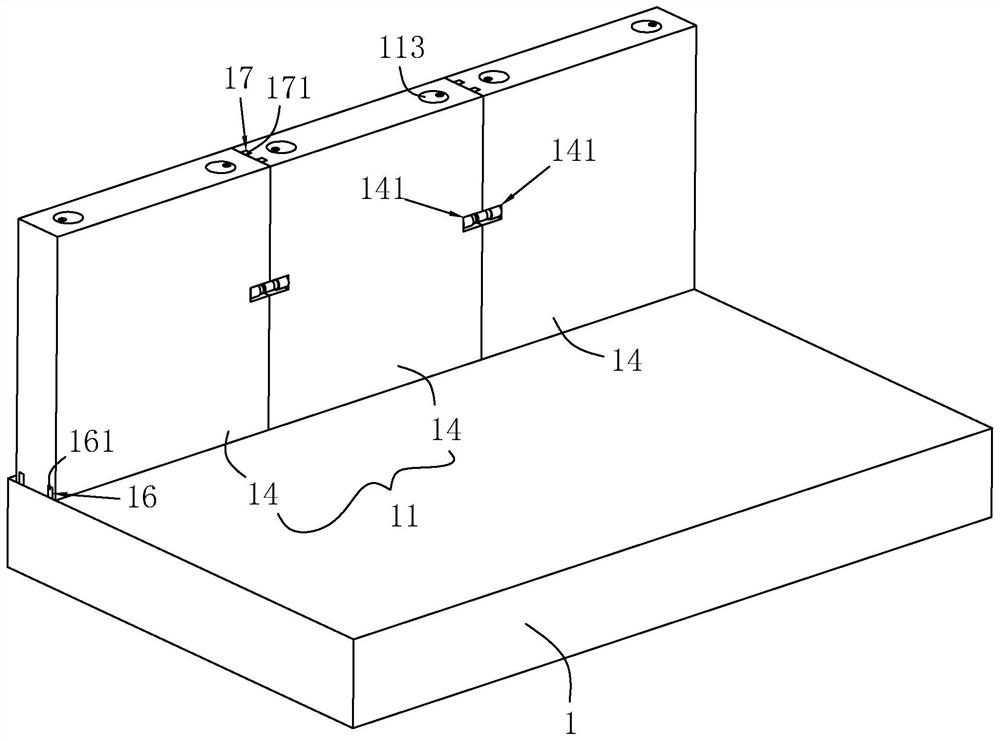

[0042] refer to figure 1 , is a parapet connection structure disclosed in the present invention, including a wall body 11 located on the edge of the roof 1 .

[0043] Such as figure 1 As shown, in order to install and fix the wall body 11 conveniently, the wall body 11 includes a plurality of splicing bodies 14 spliced together.

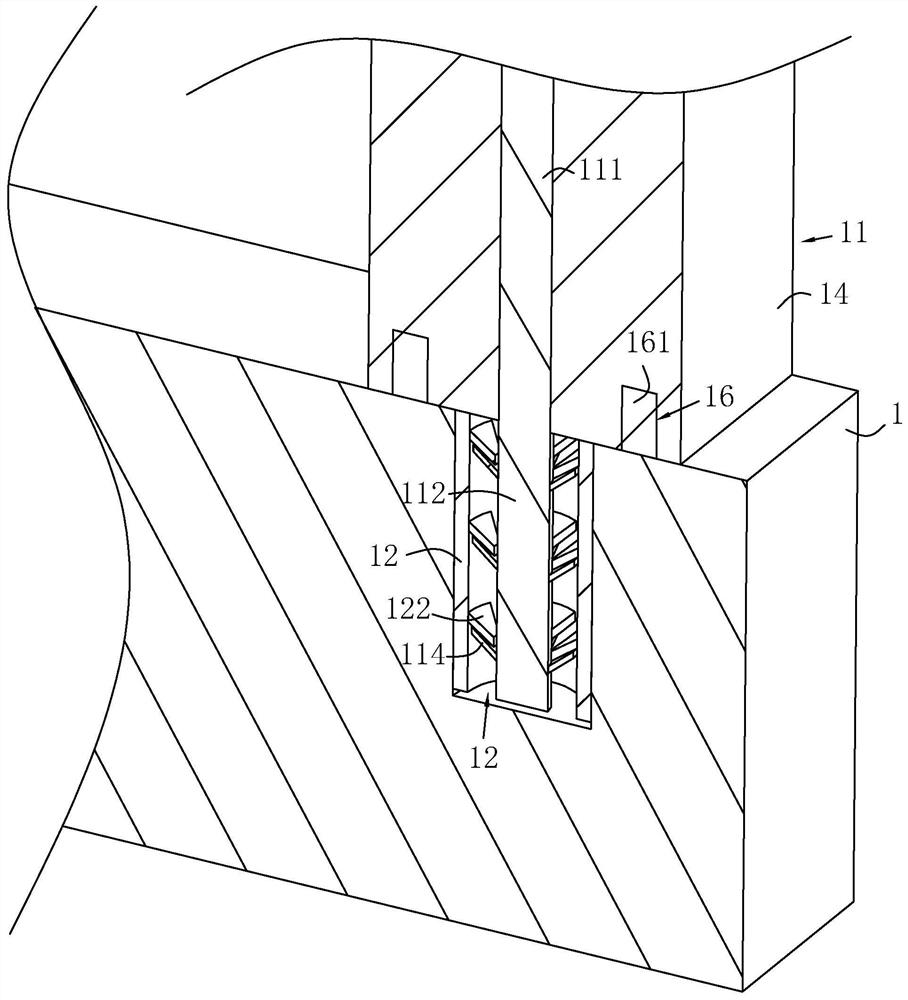

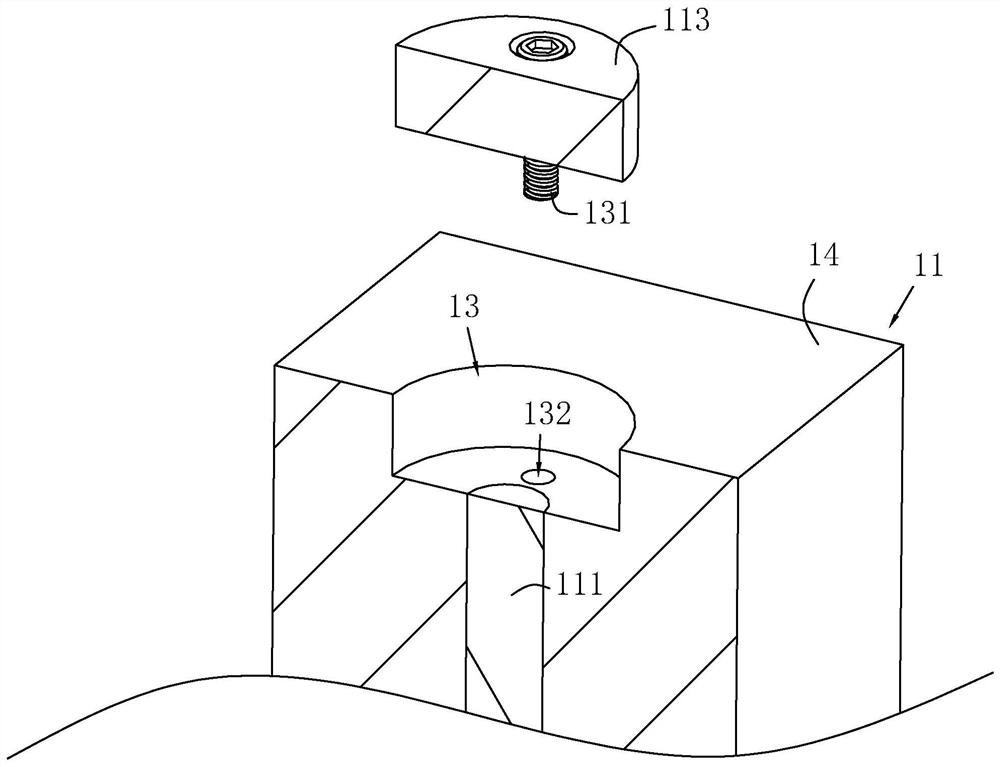

[0044] combine figure 1 and figure 2 In order to improve the sealing effect between the splicing body 14 and the roof 1, and prevent the accumulated water on the roof 1 from flowing out along the gap between the splicing body 14 and the roof 1, each splicing body 14 faces the surface of the roof 1. On and on both sides of the splicing body 14 are provided with a first sealing groove 16, the two ends of the first sealing groove 16 are set through the splicing body 14, and the surface of the roof 1 facing the splicing body 14 i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com