Natural gas and steam combined power generation device for power generation ship

A combined power generation and natural gas technology, which is applied to steam engine devices, fuel heat treatment devices, oil supply devices, etc., can solve the problems of high waste heat utilization rate and low waste heat utilization rate, achieve high waste heat utilization rate and ensure heat exchange effect Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment

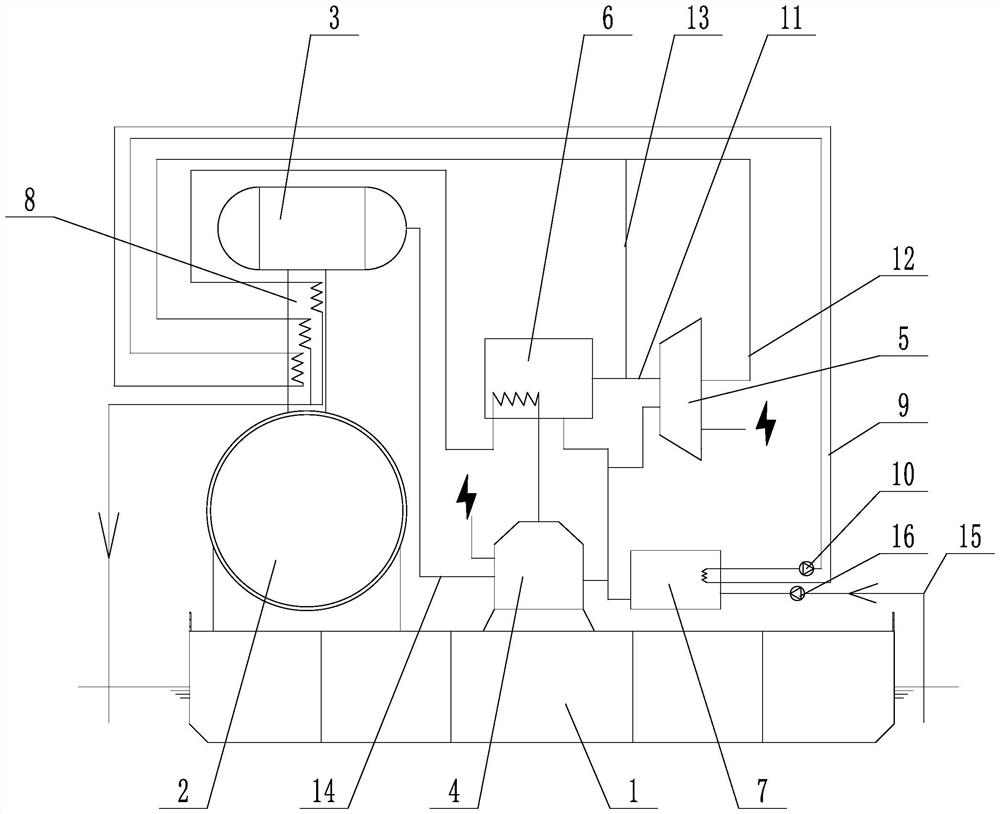

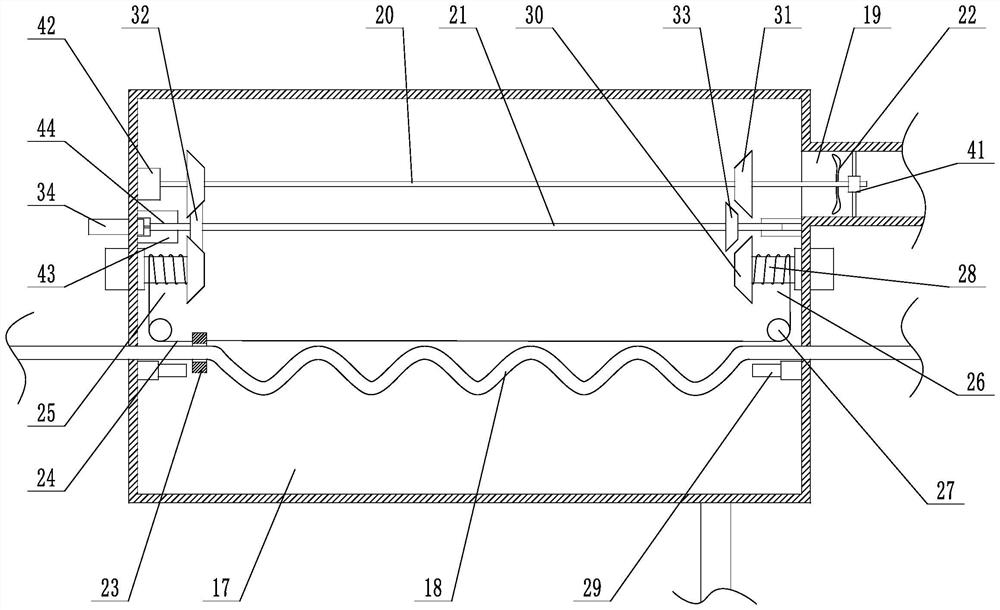

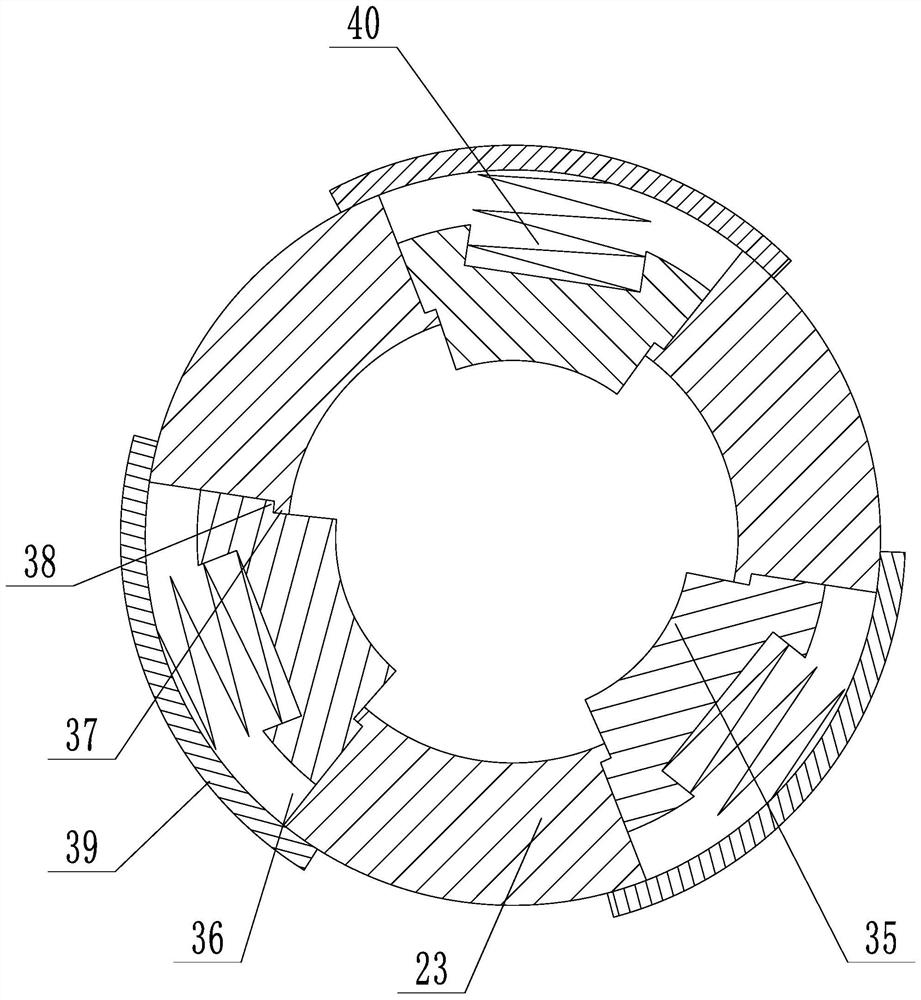

[0023] Embodiment: a natural gas and steam combined power generation device used on a power generation ship (see attached figure 1 , attached figure 2 , attached image 3 ), including LNG storage tank 2, regasification buffer tank 3, natural gas generator 4, steam generator 5, waste heat exchanger 6, refrigeration heat exchanger 7, LNG storage tank and The gasification pipeline 8 is connected between the regasification buffer tanks, and the regasification buffer tank supplies natural gas to the natural gas generator for power generation of the natural gas generator, and the flue gas discharged by the natural gas generator is firstly heated in the waste heat exchanger After that, the flue gas heats the natural gas in the gasification channel, and finally discharges it to the outside. The steam generated in the waste heat exchanger is used to generate electricity for the steam generator, and the waste heat of the steam generator heats the natural gas in the gasification channe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com