Variable grating micro-signal separation device and manufacturing method thereof

A separation device and micro-signal technology, which is applied in the direction of measuring devices, particle size analysis, and analysis materials, etc., can solve the problems that affect the accurate judgment of signals, the difficulty of the process, and the inconvenience of implementation, so as to avoid superposition, control the process, and improve accuracy. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

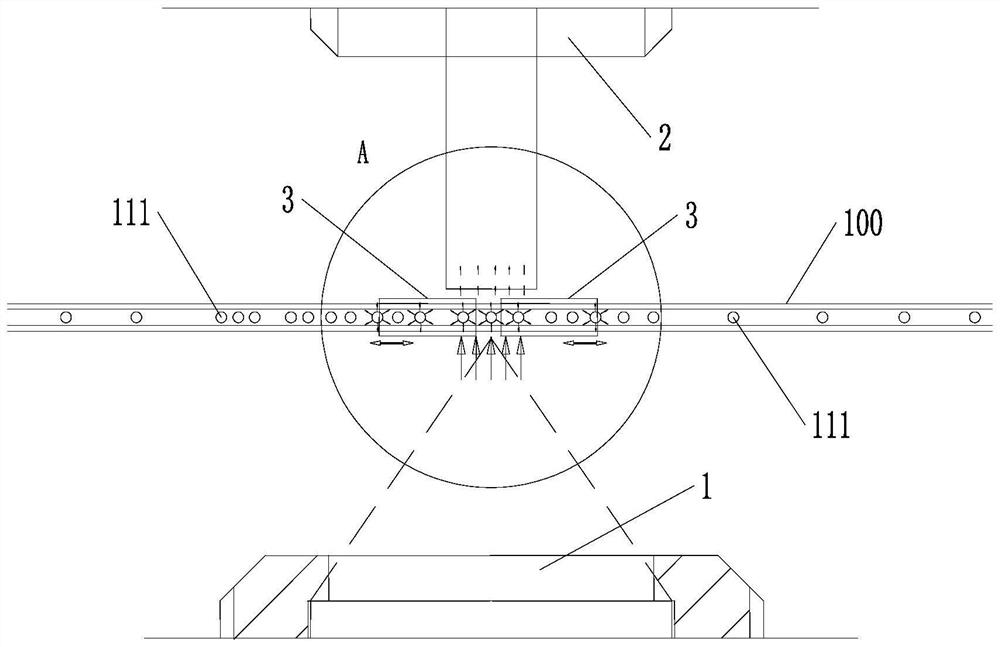

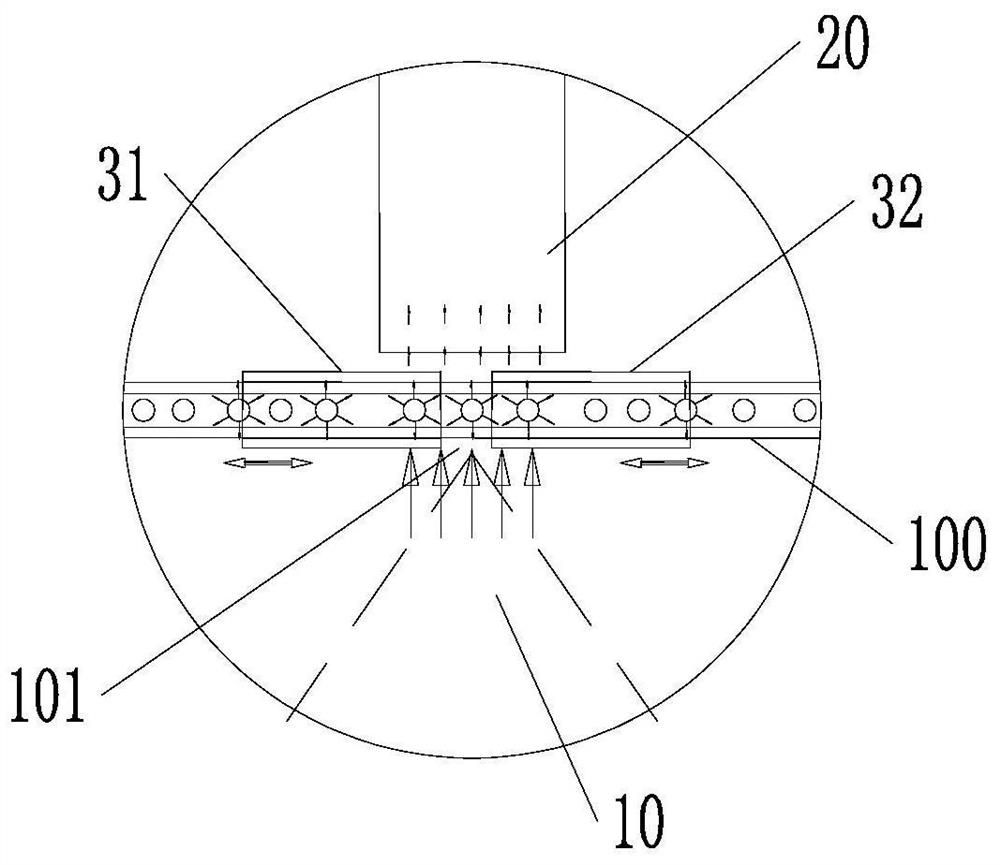

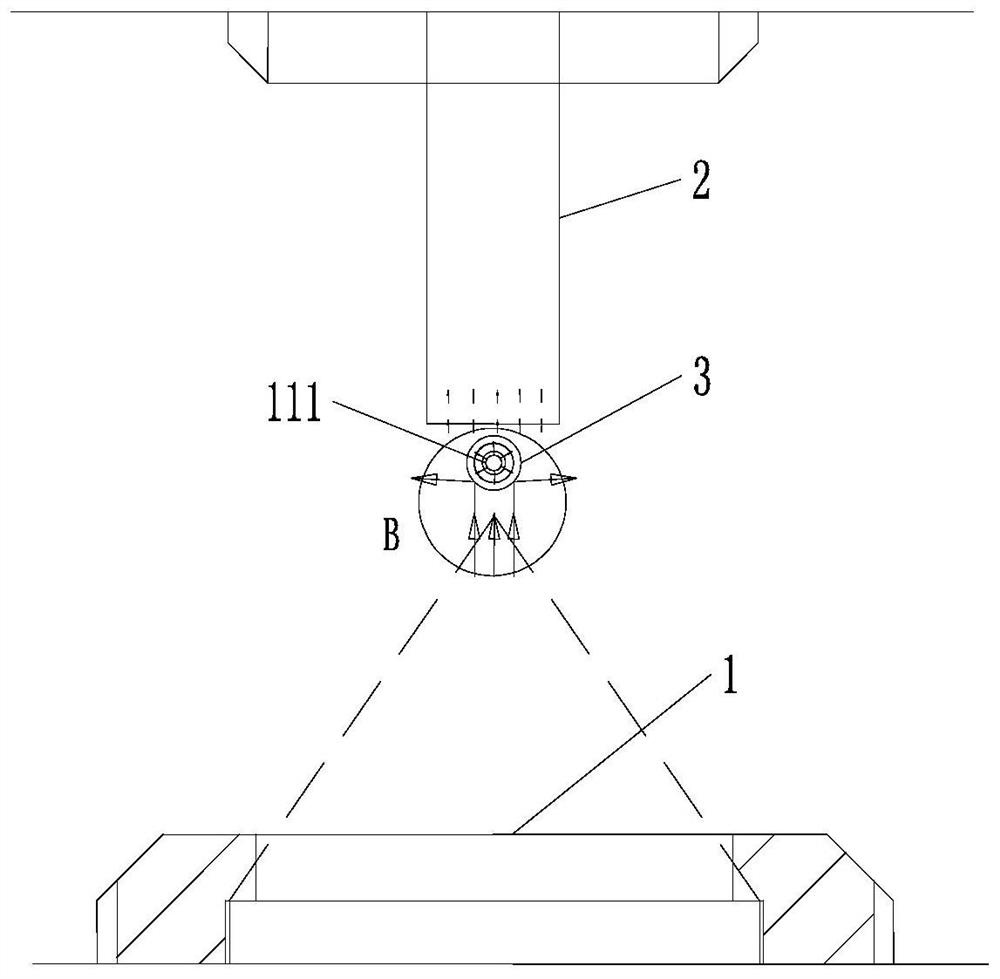

[0021] Below in conjunction with embodiment and attached Figures 1 to 4 The present invention is further described.

[0022] A variable grating micro-signal separation device, such as figure 1 As shown, it includes a capillary 100, an excitation light source 1 and a signal receiver 2, the capillary 100 is located between the excitation light source 1 and the signal receiver 2, an excitation light source 1 is arranged on one side of the capillary 100, and the excitation The emitting head 10 of the light source 1 is used to emit excitation light, and the emitted excitation light passes through the transparent capillary 100 and hits the substance to be detected 111 flowing through the capillary 100. The substance to be detected 111 is a sample particle or a gene fragment, and the Composed of several particles or gene fragments, the fluorescent signal emitted by them penetrates the transparent capillary 100 again and enters the signal receiver 2 on the other side of the capillar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com