Positive-pressure explosion-proof box three-dimensional frame

A three-dimensional, box-like technology, applied in printing, printing devices, engine sealing, etc., can solve the problems of easy deformation, heavy workload, etc., and achieve the effect of strong bearing capacity, reliable and simple installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

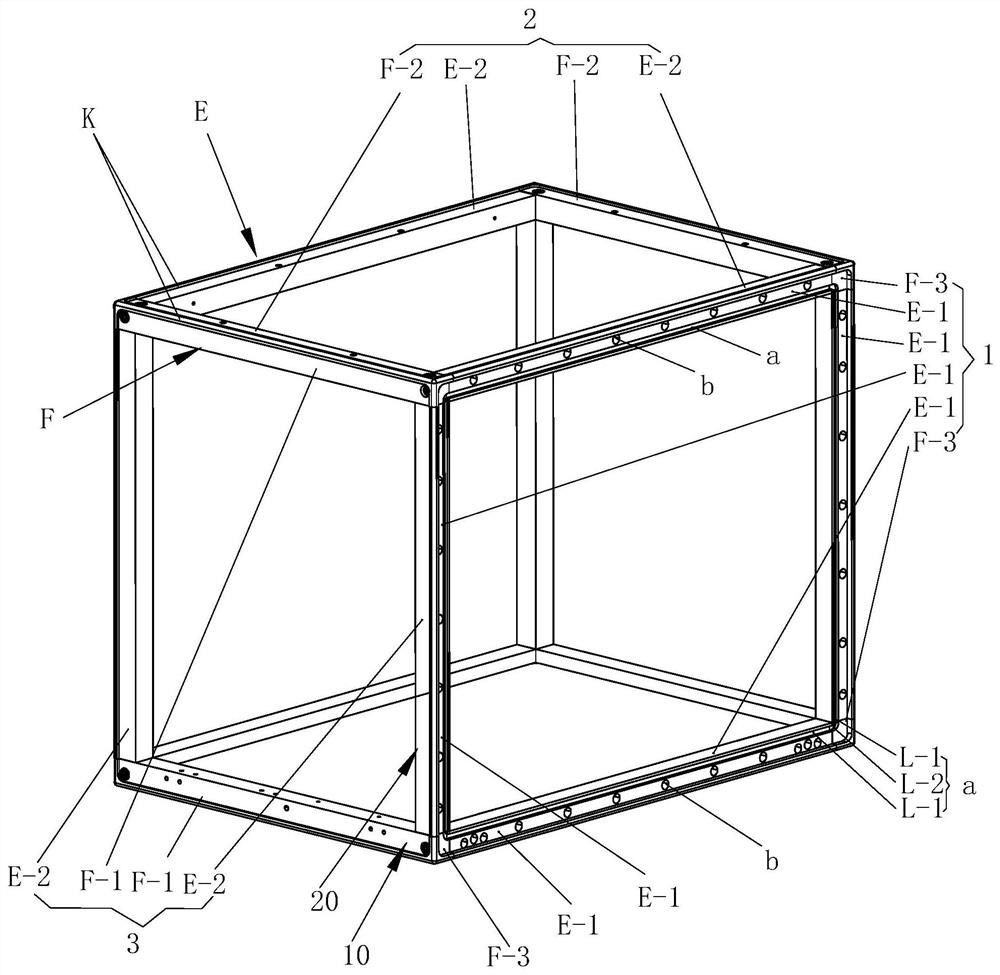

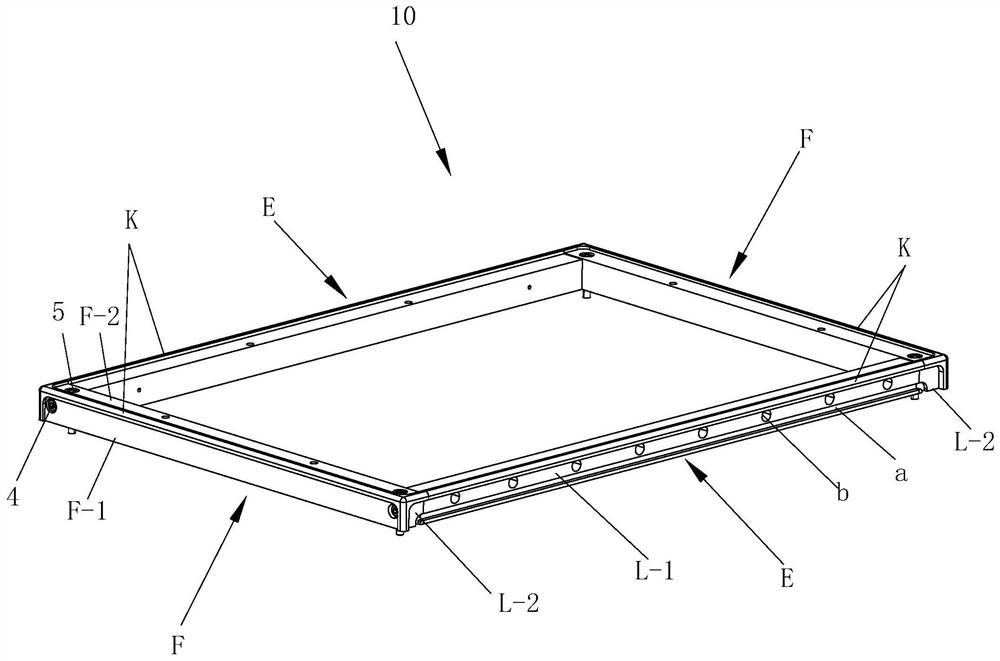

[0018] See Figure 1 to Figure 8 , this embodiment includes two planar frames 10 connected by two type I rods E and two type II rods F through first screws 4, and four uprights 20 are connected between the two planar frames 10 through second screws 5 connection, column 20 adopts type I rod E.

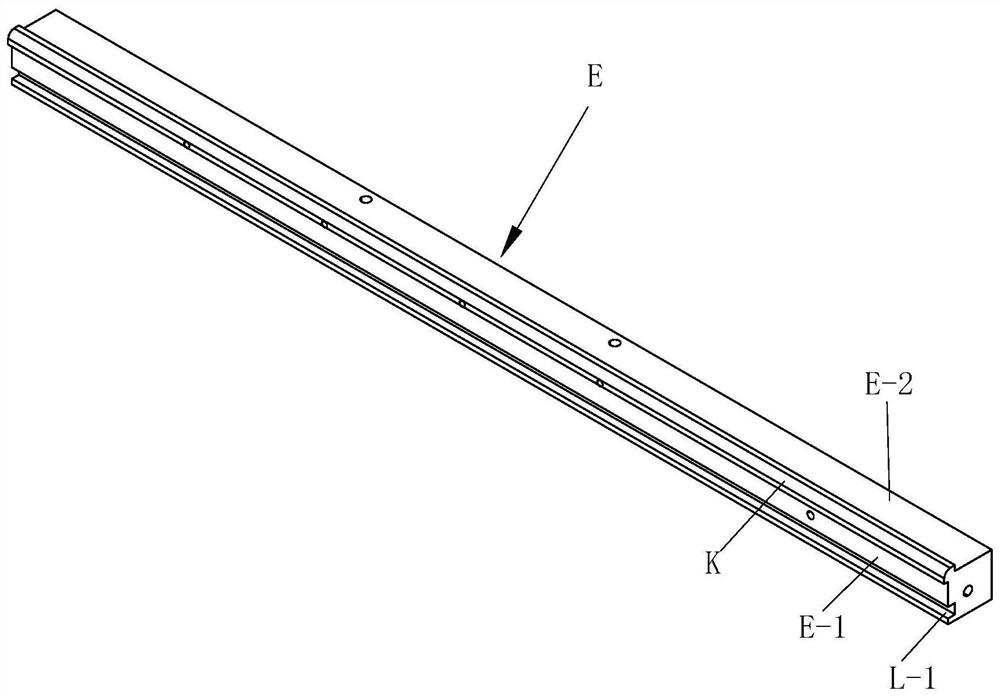

[0019] The first surface E-1 of the Type I rod is provided with a straight groove L-1 through both ends, and the surface away from the straight groove L-1 and perpendicular to the first surface E-1 of the Type I rod is the second surface E of the Type I rod -2. A flange K is provided at the junction of the first surface E-1 of the type I rod and the second surface E-2 of the type I rod.

[0020] The end face F-3 of the type II rod is provided with an arc groove L-2, and the two perpendicular surfaces opposite to the arc groove L-2 are the first face F-1 of the type II rod and the second face of the type II rod. Two faces F-2, the junction of the first face F-1 of type II rod and the s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com