Tufting processing treatment method for producing cotton textile yarns

A textile yarn and processing method technology, which is applied in the field of cotton textile yarn manufacturing and delinting processing, can solve the problems of textile cotton thread being difficult to scrape off, textile yarn breaking, and textile yarn lint being difficult to remove, so as to avoid scratching The effect of breaking and convenient reversing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

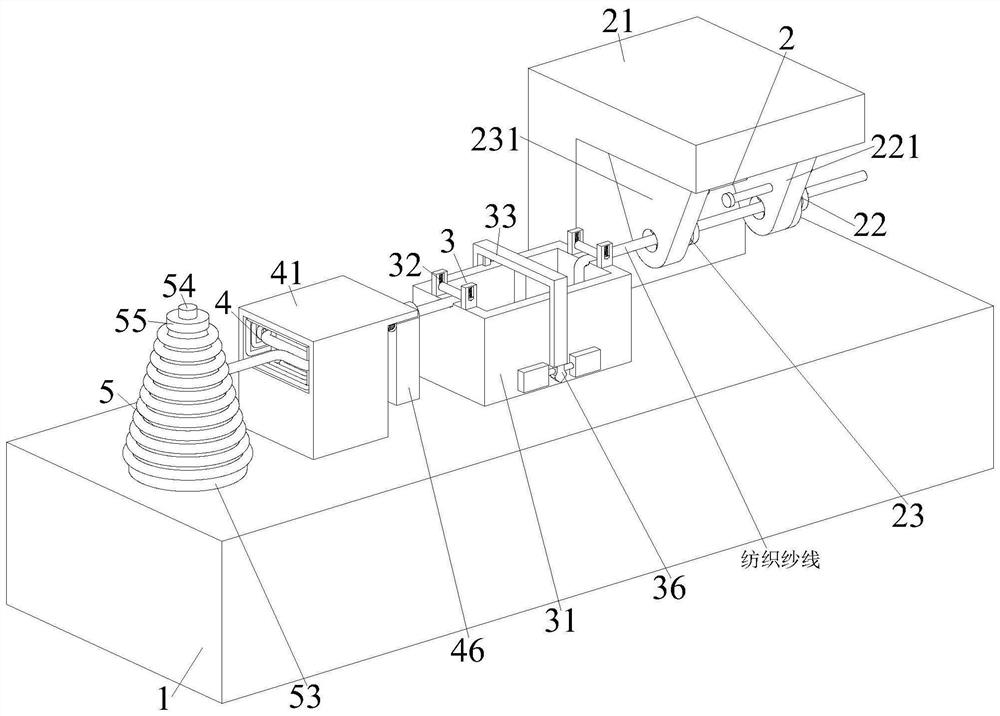

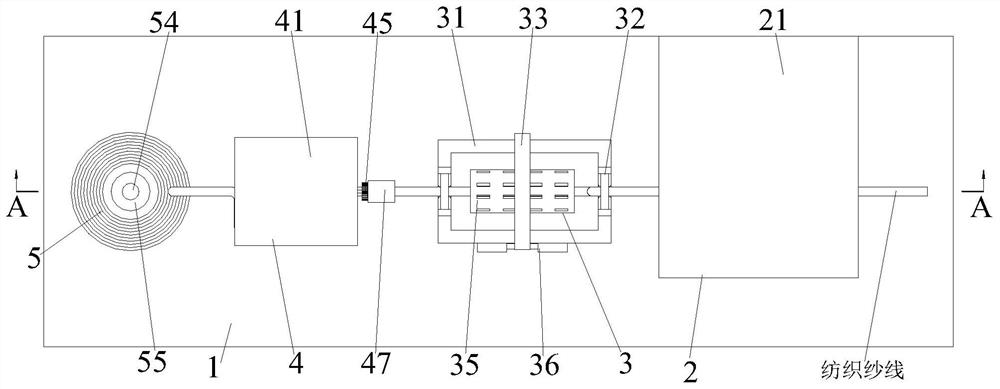

[0042] In order to make the technical means realized by the present invention, creative features, goals and effects easy to understand, the following combination Figure 1 to Figure 11 , to further elaborate the present invention.

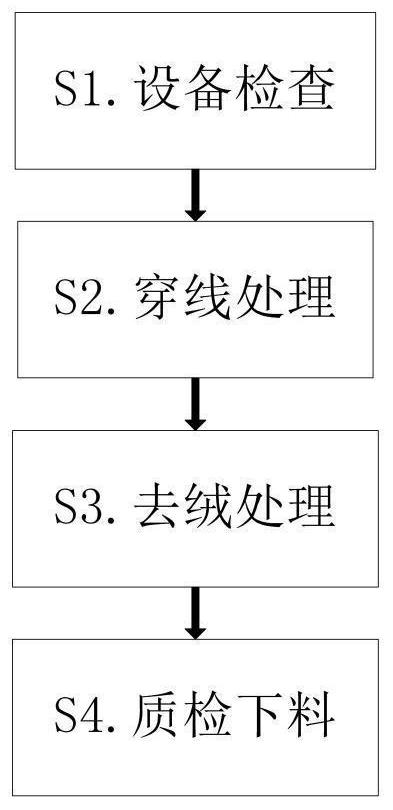

[0043] A cotton textile yarn manufacturing delint processing method, the specific processing method is as follows:

[0044] S1. Equipment inspection: before using the textile yarn delinting equipment to delint the textile yarn, check it;

[0045] S2. Threading treatment: manually pass the textile yarn through the velvet device 2, the soaking device 3, and the scraping and drying device 4, so that the yarn is wound on the winding device 5;

[0046] S3. Delint treatment: scrape off the outer suede of the textile yarn through the delint device 2, and smooth the surface of the yarn after the delint through the soaking device 3 and the scraping and drying device 4, and pass the yarn through the collection Roll device 5 rewinds;

[0047] S4. Quality i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com