A wireline core drilling tool

A technology of core drilling tools and ropes, which is applied in the direction of extracting undisturbed core devices, earthwork drilling, wellbore/well components, etc., which can solve the problems of unrecoverable ejection, increased difficulty of core extraction, and poor reliability, etc. To achieve the effect of ensuring quality and recovery rate, shortening the time of exporting work, and improving the reliability of use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0064] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

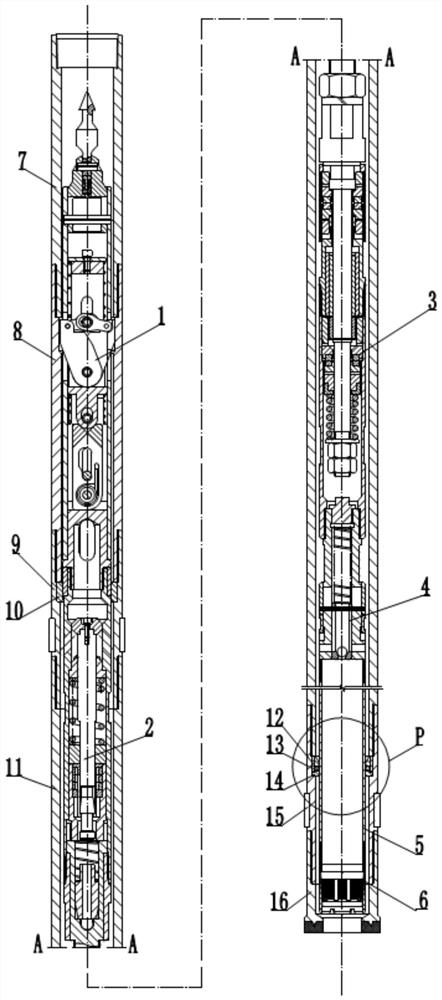

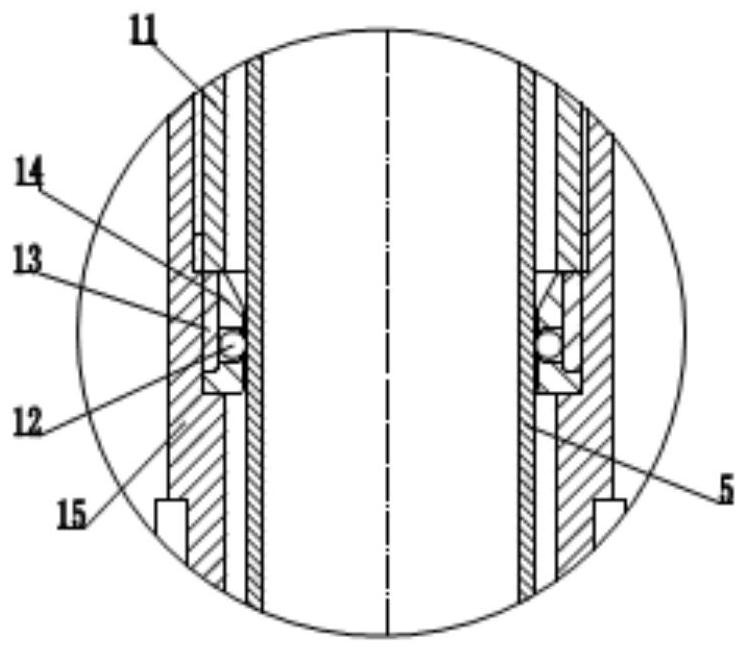

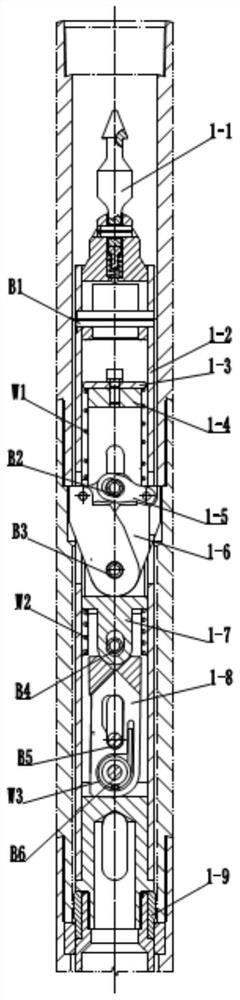

[0065] see figure 1 , figure 2 , the present invention provides a wireline coring drilling tool, which includes an outer tube assembly and an inner tube assembly; the inner tube assembly is sequentially provided with a bullet positioning mechanism 1, an in-position reporting and a core blockage alarming mechanism 2 from top to bottom , a single-action mechanism 3, a core tube one-way valve mechanism 4, a core tube 5 and a core breaking mechanism 6, the bullet clamp positioning mechanism 1 adopts a multi-point hinged mode, and the in-place reporting and core blockage alarm mechanism 2 are integrated into one, The single-action mechanism 3 adopts an upper and lower group of PDC bearings and a TC bearing arranged in the middle, and the core tube one-way valve mechanism 4 controls the opening and closing of the one-way valve through the cooperati...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com