Quick installing device of hydraulic annular wellhead casing flange

A casing method and fast technology, applied in the direction of wellbore/well components, earthwork drilling, sealing/isolation, etc., can solve the problems of high risk, the inability of operators to install close to the wellhead, time-consuming and labor-intensive problems, and protect life safety , The clamping process is convenient and fast, and the effect of shortening the rescue time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

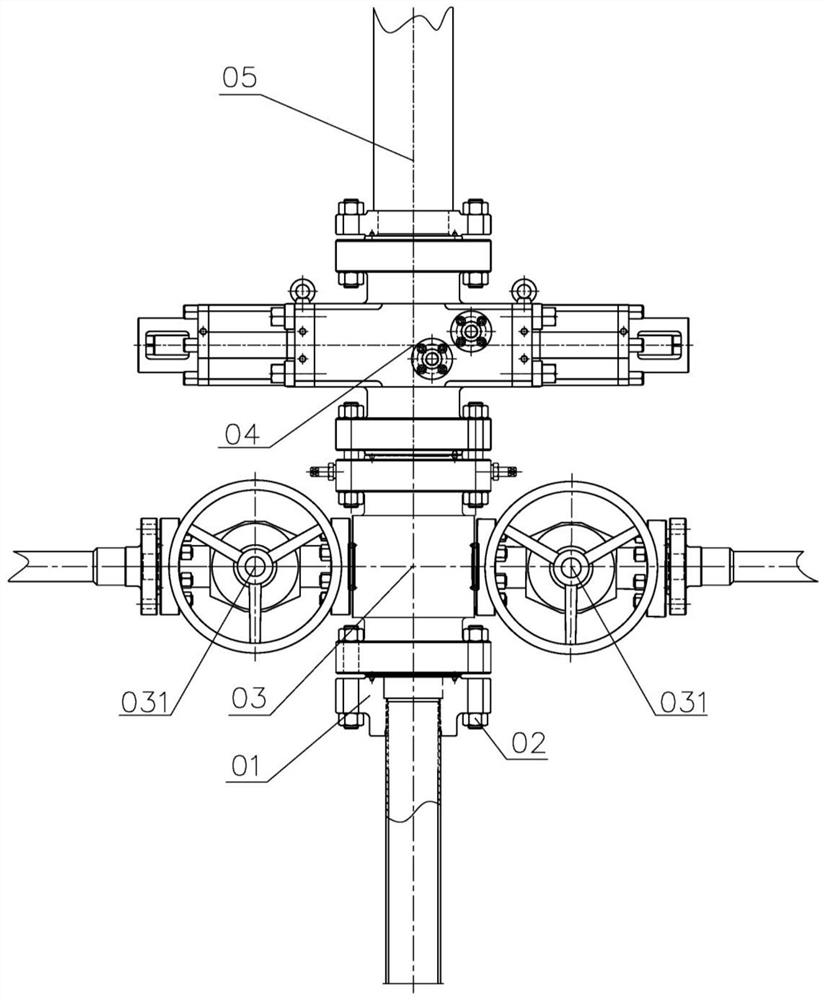

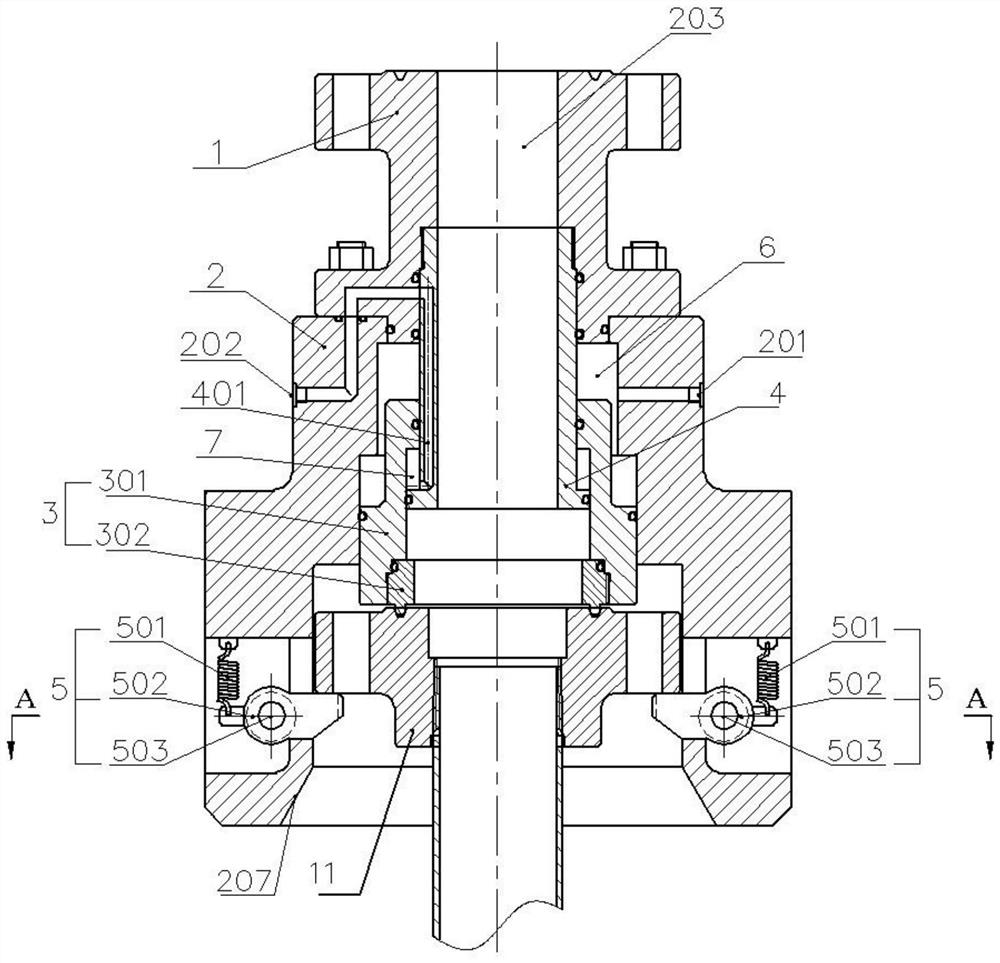

[0054] In order to make the purpose, advantages and features of the present invention more clear, the hydraulic annular wellhead casing flange quick-installing device proposed by the present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

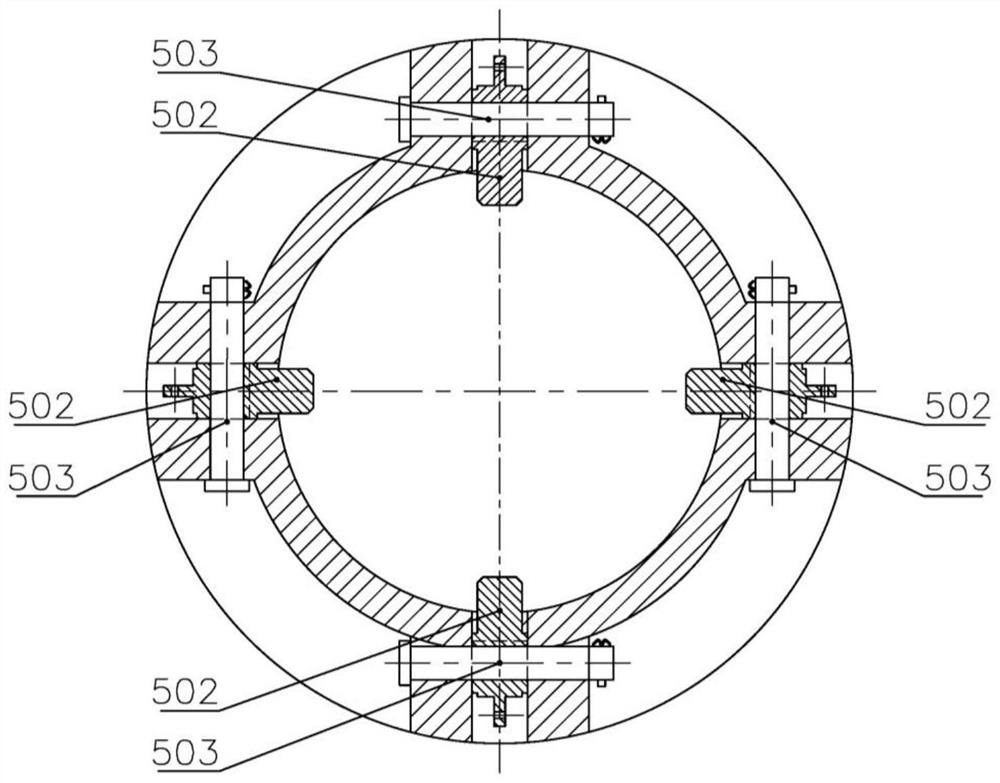

[0055] Such as figure 2 As shown, the device includes a main housing, an inner cylinder 4 , a piston assembly 3 , and at least two quick locking assemblies 5 .

[0056] The main shell such as Figure 2 to Figure 5 As shown, it includes the body 2, the upper transition flange 1 arranged on the upper end of the body 2, and the inner cavity 203 that penetrates up and down. Cavity, in this embodiment, the upper opening cavity is located in the upper transition flange 1, and the piston cavity and sleeve flange accommodating cavity are located in the body 2. The inner cylinder 4 is coaxially arranged in the inner cavity 203, and its upper part is fixedly connected with...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com