Pistons for internal combustion engines

An internal combustion engine and piston technology, applied in the field of internal combustion engines, can solve problems such as ignition belt rupture and pressure fluctuation amplification, and achieve the effect of reducing the risk of rupture

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

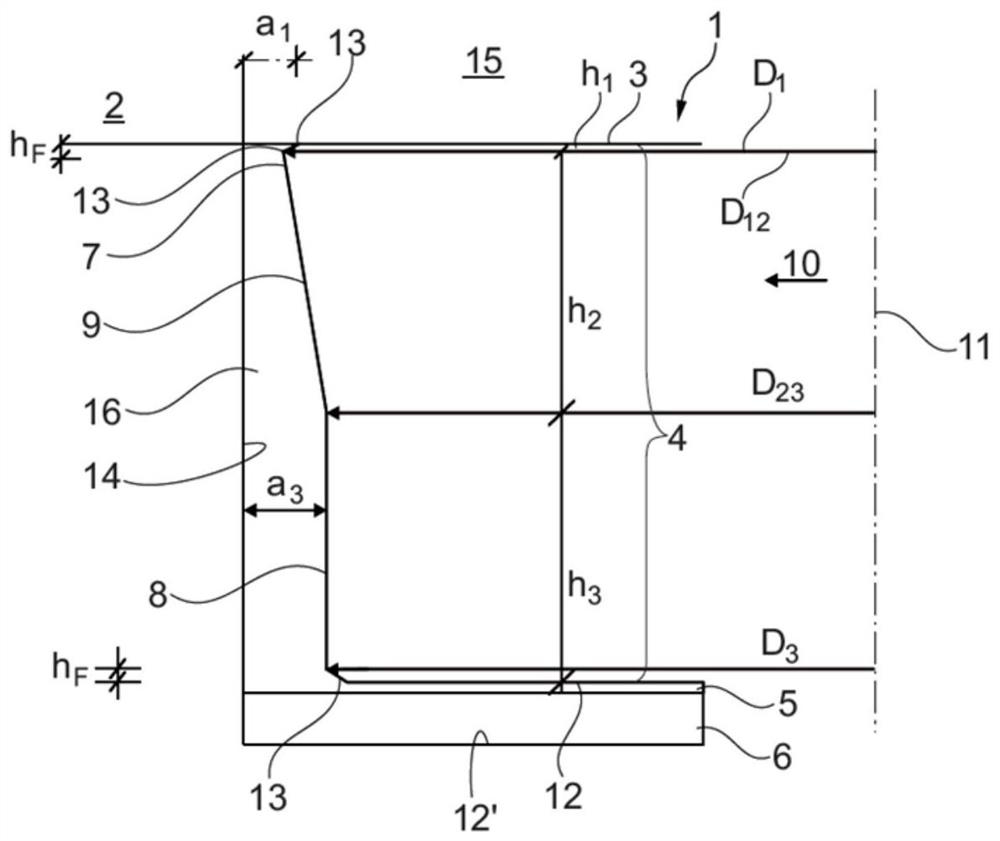

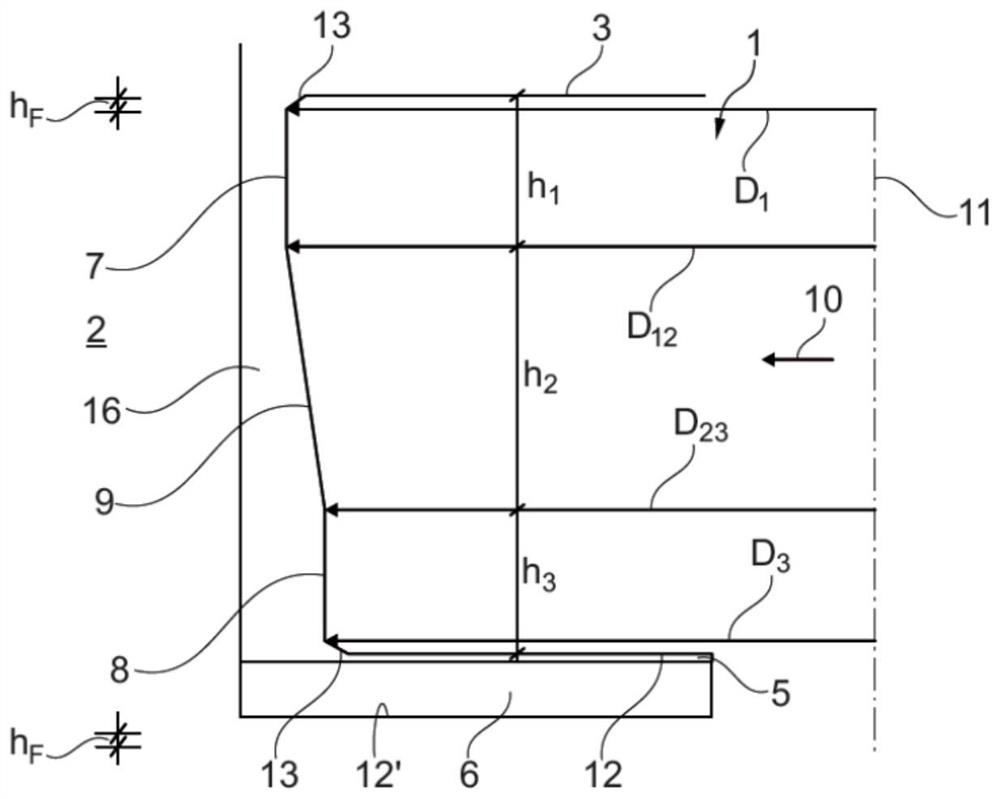

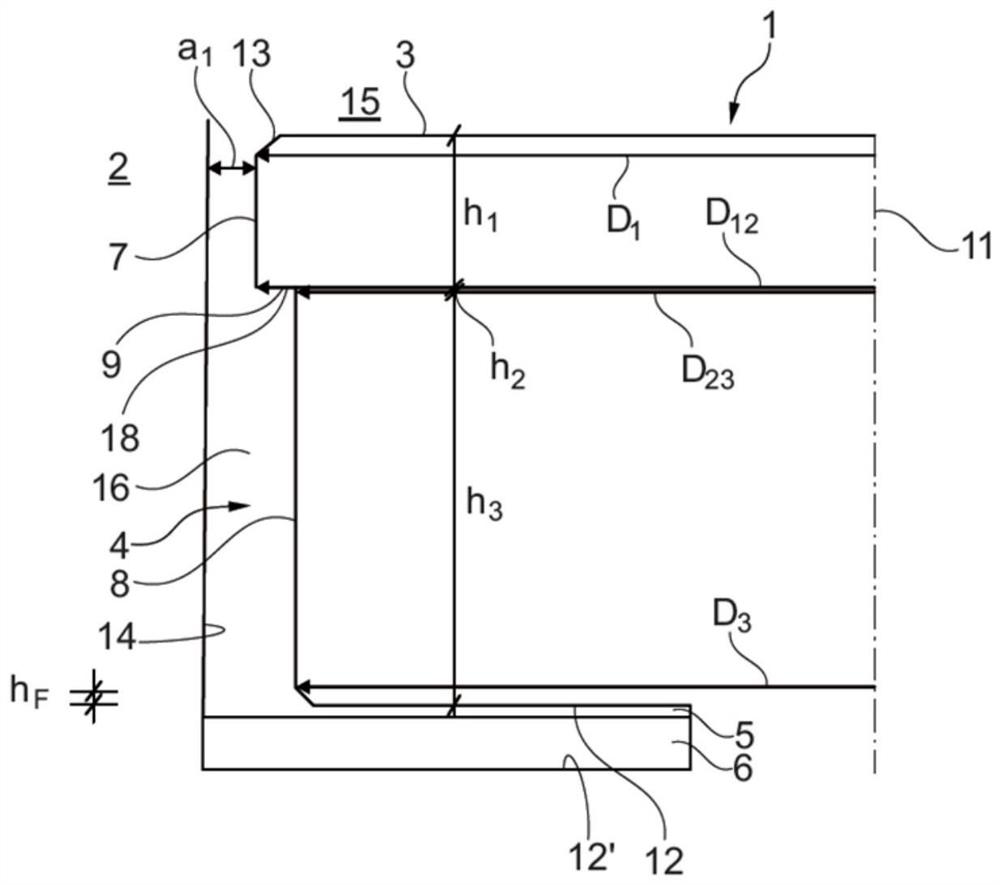

[0029] corresponds to Figure 1 to Figure 6 A piston 1 according to the invention for an internal combustion engine 2 comprises a piston head 3 , a surrounding ignition band 4 and at least one annular groove 5 adjoining the ignition band for receiving a piston ring 6 . Now provided according to the invention is a first ignition band part 7 adjacent to the piston head 3, a third ignition band part 8 adjacent to the annular groove 5 and a second ignition band part 9, the second ignition band part 9 connecting the two The ignition strip parts 7, 8 are arranged between them. The annular groove 5 has groove sides 12, 12', preferably parallel to the piston axis 11 and extending in a radial direction 10, in particular a groove side 12 of the proximal end of the piston head and a distal end of the piston head. 12' of groove sides. The first ignition strip part 7 has an axial height h 1 , the second ignition strip portion 9 has an axial height h 2 , the third ignition strip portion...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com