A device and method for measuring inner hole size suitable for rotary parts

A technology of inner hole size and measuring device, which is applied in the direction of mechanical diameter measurement, etc., can solve the problems of poor stability and accuracy of measurement results, machining accuracy error of rotating body parts, and difficulty in ensuring parallelism of measuring tool bars. The effect of avoiding gap errors and simplifying the clamping process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

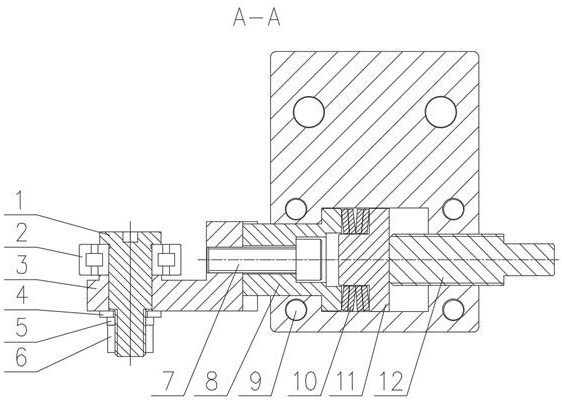

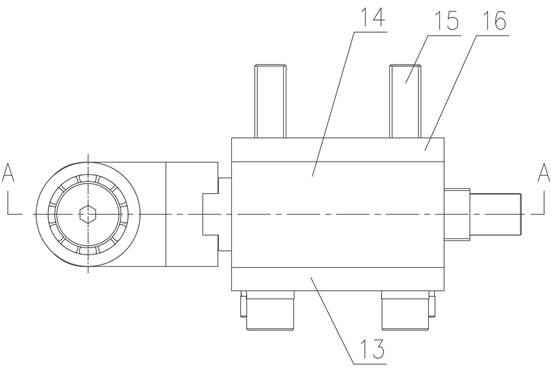

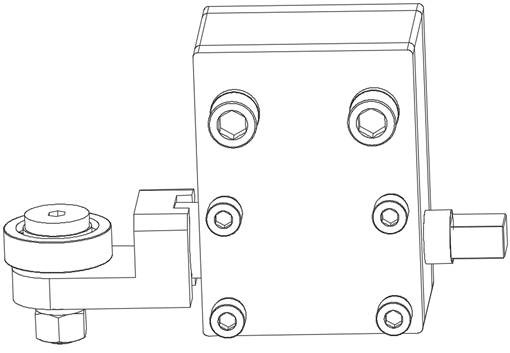

[0044] see Figure 1~7 In the preferred embodiment of the present invention, the device for measuring the inner hole size of parts of a revolving body includes a pallet 18 and a measuring rod 22 arranged in the guide rail of a lathe 17 . Wherein, the guide rail includes two guide rail pairs 19 oppositely arranged, and a chute 20 is formed between the two guide rail pairs 19 , and then the supporting plate 18 is matched and arranged in the chute 20 , and can slide reciprocally in the chute 20 . It should be noted that, in the preferred embodiment, the extending direction of the chute 20 is recorded as the longitudinal direction of the lathe (ie Figure 5 The horizontal direction shown in ), and the horizontal direction perpendicular to the longitudinal direction of the lathe is recorded as the transverse direction of the lathe (ie Figure 5 vertical orientation shown in ). In addition, during actual measurement, the axial direction of the workpiece to be measured after being ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com