Shield tail brush dynamic sealing performance testing device and testing method thereof

A technology of dynamic sealing and testing device, which is applied in liquid/vacuum measurement for liquid tightness, and by detecting the appearance of fluid at the leakage point, etc., can solve the problem of low test accuracy of the pressure bearing capacity of the shield tail brush, and achieve accurate The effect of data support

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 3

[0041] Embodiment 3, a kind of test method of dynamic sealability testing device of shield tail brush, the steps are as follows:

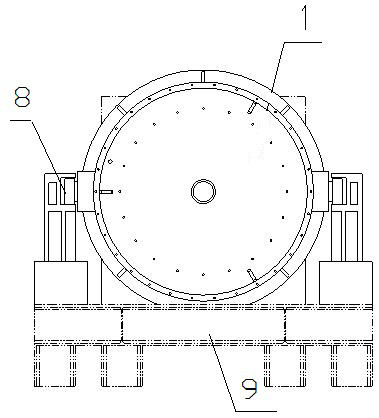

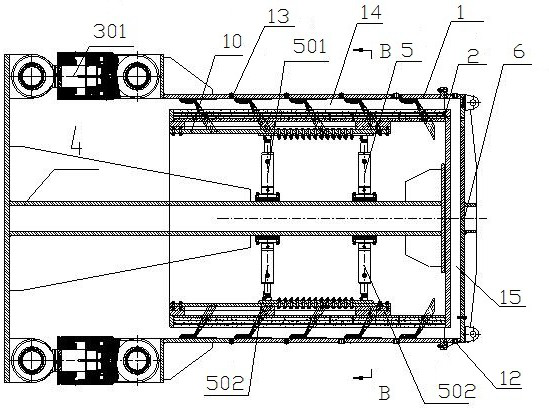

[0042] S1: Assemble the test device so that the inner cylinder 2 is located in the outer cylinder 1, and the side wall of the outer cylinder 1 and the side wall of the inner cylinder 2 form a sealed grease chamber 14; A sealed pressurized chamber 15 is formed at the rear of the cylinder body 2 ; the shield tail brush 11 is located in the sealed grease chamber 14 . Wherein, the steps of test device assembly are as follows:

[0043] S1.1: Fix the mounting frame 9 at the designated position;

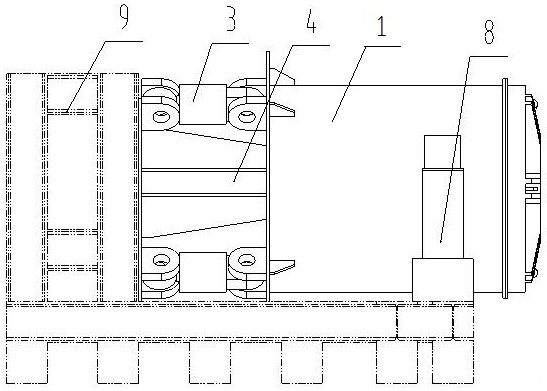

[0044] S1.2: Install the supporting beam 4 and the hinged supporting frame 8 on the mounting frame 9 in sequence;

[0045] S1.3: Install the upper radial telescopic oil cylinder 501 and the lower radial telescopic oil cylinder 502 on the support beam 4;

[0046] S1.4: Connect the inner cylinder 2 to the upper radially telescopic oil cylinder 501 and the lower...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com