Plug-in switch device with concave surface

A switchgear, pluggable technology, applied in protection switches, emergency protection devices, parts of protection switches, etc., can solve the problems of wear and tear of nameplates and signs, reduce complaints, improve economic benefits, and improve long-term reliability. sexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

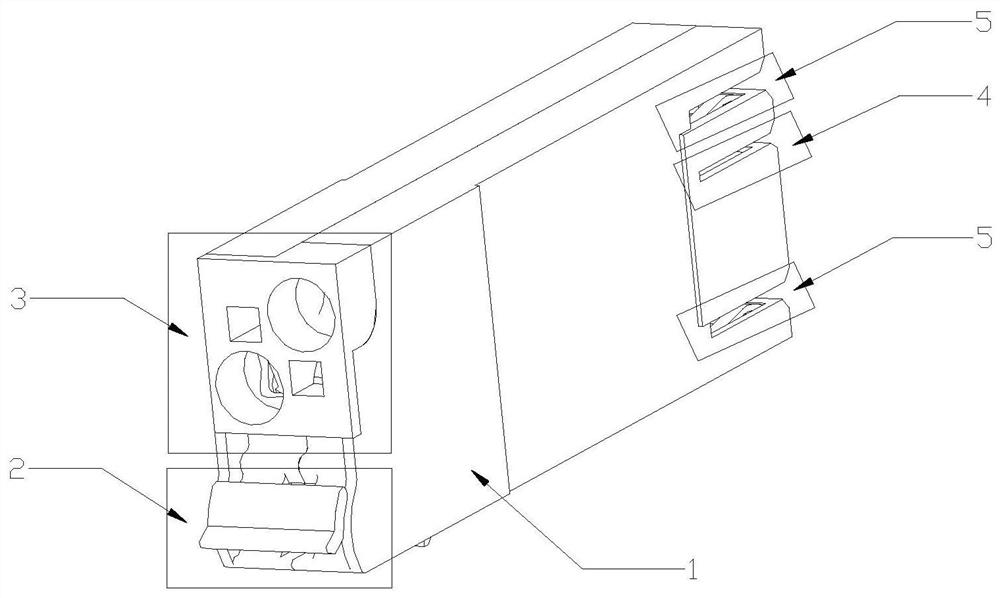

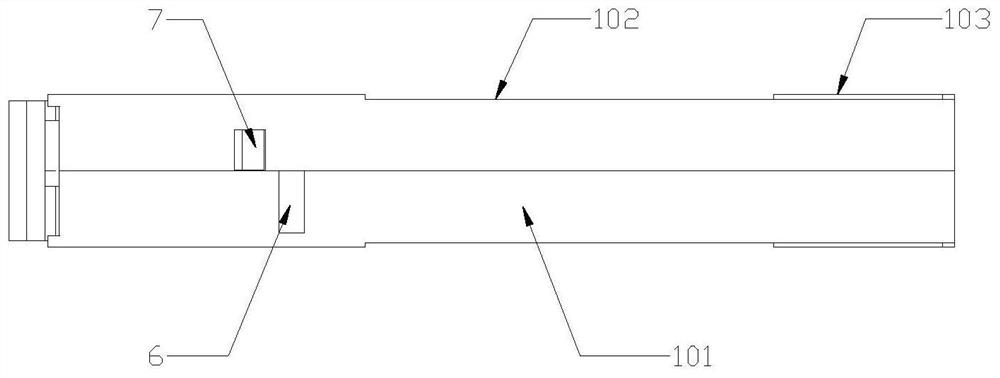

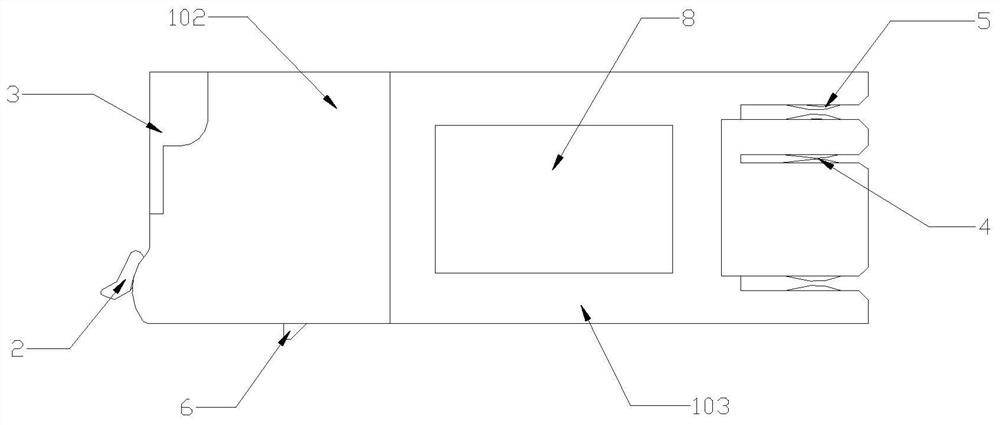

[0025] see Figure 1-4 , in an embodiment of the present invention, a pluggable switch device with a concave surface, including a housing 1, a housing body 101, a positioning surface 102, a groove 103, an operating end 2, an incoming and outgoing wire end 3, a signal port 4, an incoming and outgoing wire Clamping port 5, buckle 6, positioning groove 7, product nameplate 8, the overall shell (1) is a long rectangle, the side surface of the shell 1 is provided with a groove 103, and the front end surface of the shell 1 is provided with an operating end 2 and the cable inlet and outlet terminal 3, the signal port 4 and the cable inlet and outlet clamping port 5 are arranged on the rear end surface, and the buckle 6 and the positioning groove 7 are arranged on the bottom surface.

[0026] Wherein: the shell 1 includes a shell main body 101, and the left and right sides of the shell main body 101 are provided with a positioning surface 102 and a groove 103, and the positioning surf...

Embodiment 2

[0034] see Figure 5 , in an embodiment of the present invention, a pluggable switch device with a concave surface, including a housing 1, a housing body 101, a positioning surface 102, a groove 103, an operating end 2, an incoming and outgoing wire end 3, a signal port 4, an incoming and outgoing wire Clamping port 5, buckle 6, positioning groove 7, product nameplate 8, the overall shell (1) is a long rectangle, the side surface of the shell 1 is provided with a groove 103, and the front end surface of the shell 1 is provided with an operating end 2 and the cable inlet and outlet terminal 3, the signal port 4 and the cable inlet and outlet clamping port 5 are arranged on the rear end surface, and the buckle 6 and the positioning groove 7 are arranged on the bottom surface.

[0035] Wherein: the shell 1 includes a shell main body 101, and the left and right sides of the shell main body 101 are provided with a positioning surface 102 and a groove 103, and the positioning surfac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com