Multifunctional terminal machine

A multi-functional terminal and integrated technology, applied in the direction of electrical components, circuits, connections, etc., can solve the problems of increasing land cost, easy to produce errors, and low work efficiency, so as to improve work efficiency, reduce working time, and save land occupation resource effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

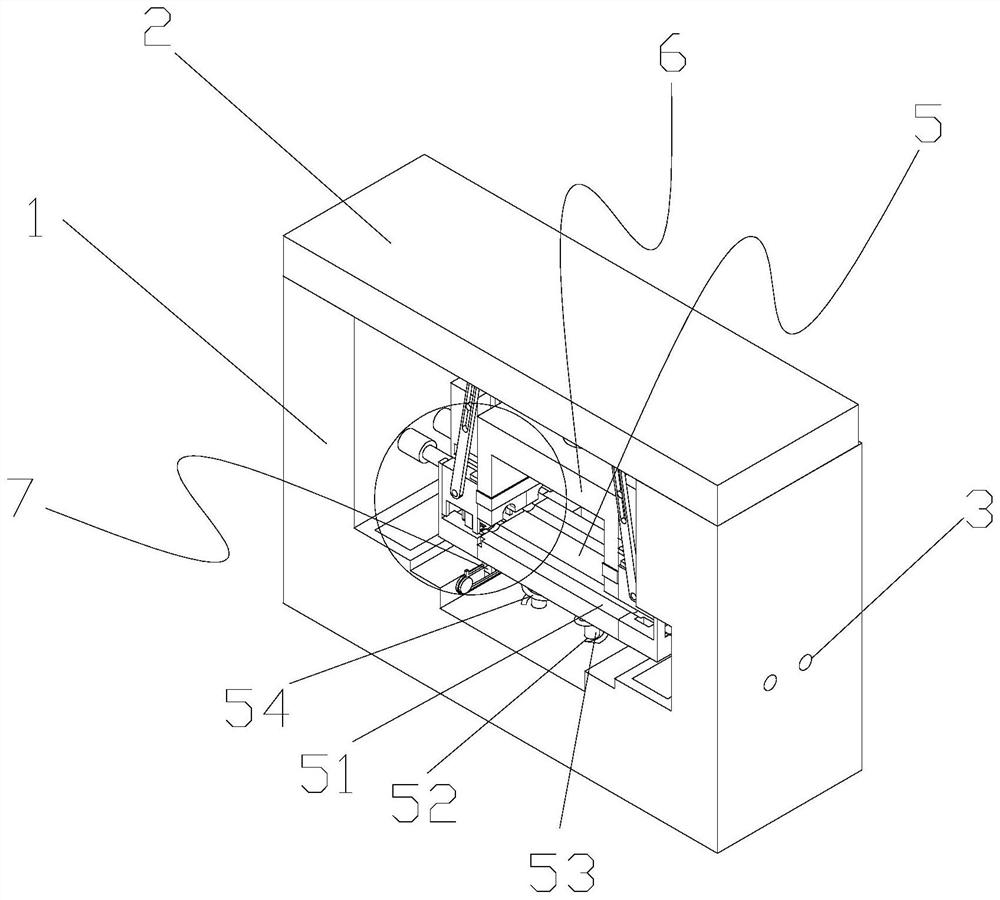

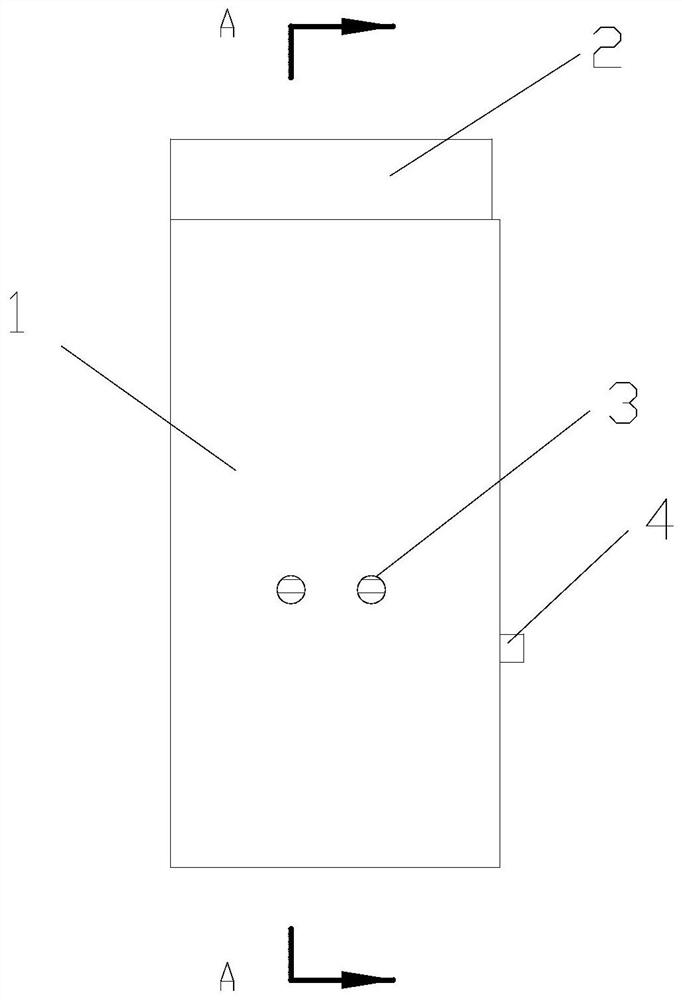

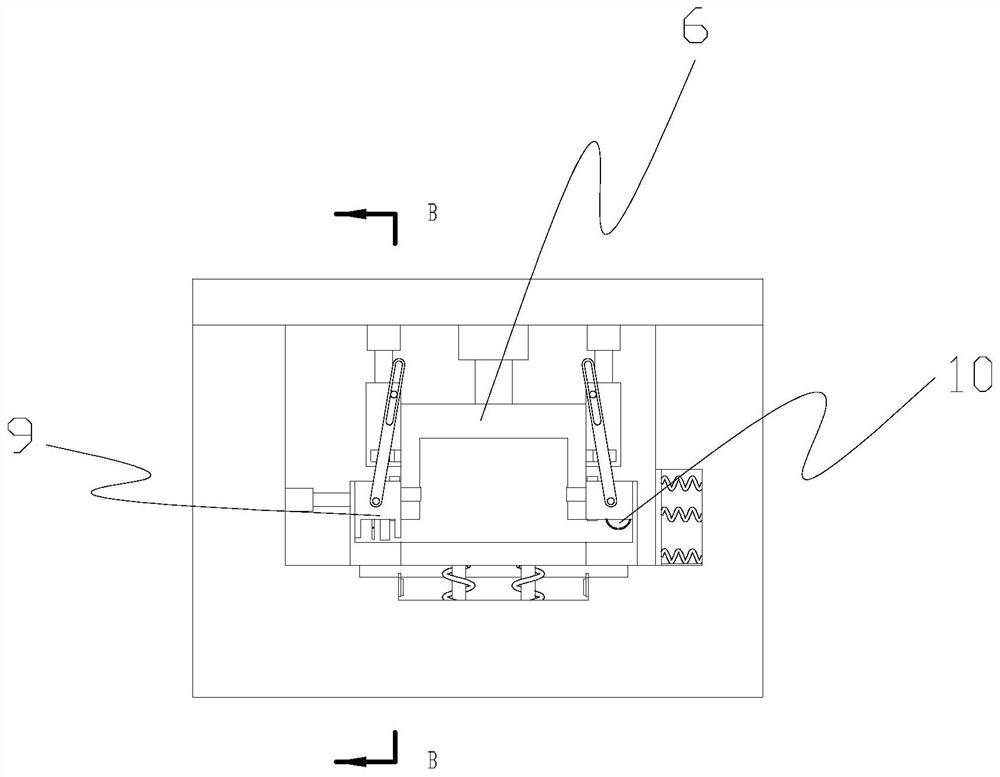

[0025] Such as Figure 1-11 As shown, a multifunctional terminal machine includes a box body 1, a cover body 2, a wire inlet 3, a discharge port 4, and an integrated terminal device 5; the box body 1 is set on the ground, and the cover body 2 is set on the ground. Above the housing, the wire inlet 3 is set on the box body, the discharge port 4 is opened on the box body, and there are multiple sets of integrated end-typing devices 5, which are evenly arranged inside the box body. Arranged in the form of strips, which effectively reduces the occupied space. Here, only two groups are set for the convenience of expression, which can be added according to requirements; the integrated end-typing device 5 includes a lifting plate 51, a guide hole 52, and a guide post 53 , the first elastic member 54, the fixing structure 6, the end structure 7, the peeling assembly 8; the lifting plate 51 is located in the box body, the guide hole 52 is opened at the bottom of the box body, and the g...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com