Tidal current energy permanent magnet generator with tooth crest temperature measurement structure

A permanent magnet generator and tidal current energy technology, which is applied in ocean energy power generation, synchronous motors with stationary armatures and rotating magnets, structural connections, etc., can solve problems such as inability to reflect the real temperature of stator teeth, and achieve accurate measurement results , the effect of a reliable reference

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

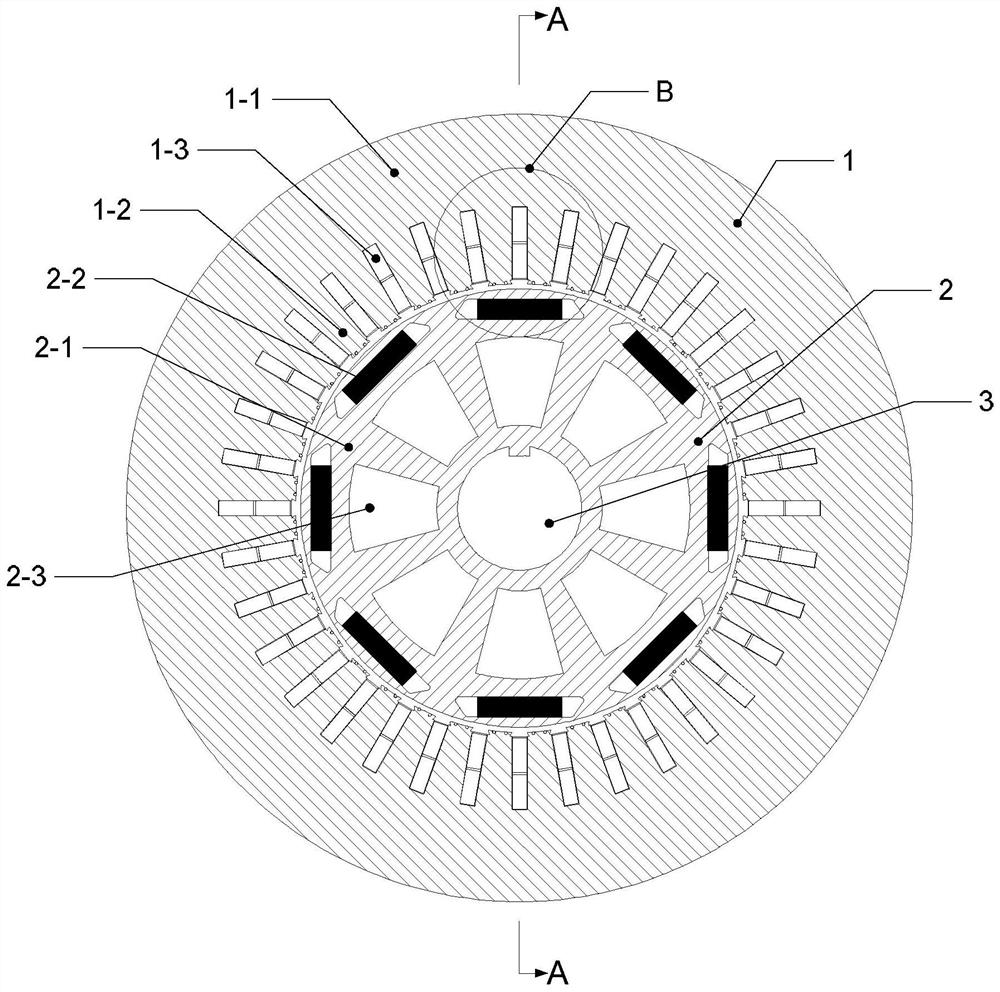

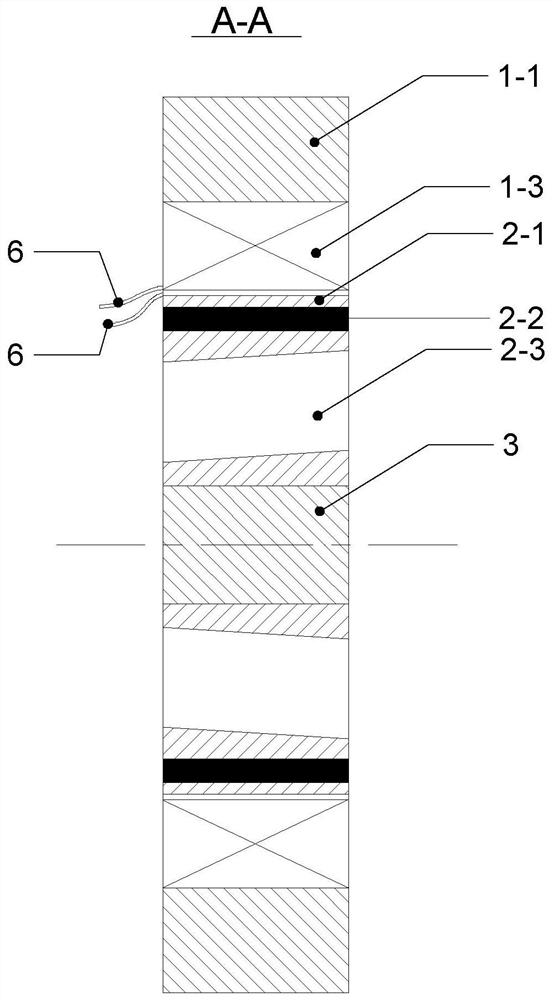

[0021] Specific implementation mode one: the following combination Figure 1 to Figure 4 This embodiment is described. The tidal current energy permanent magnet generator with tooth tip temperature measurement structure described in this embodiment includes a stator 1, a rotor 2 and a rotating shaft 3. The rotor 2 is fixed on the rotating shaft 3, and the stator 1 is arranged outside the rotor 2. , there is a radial gap between stator 1 and rotor 2;

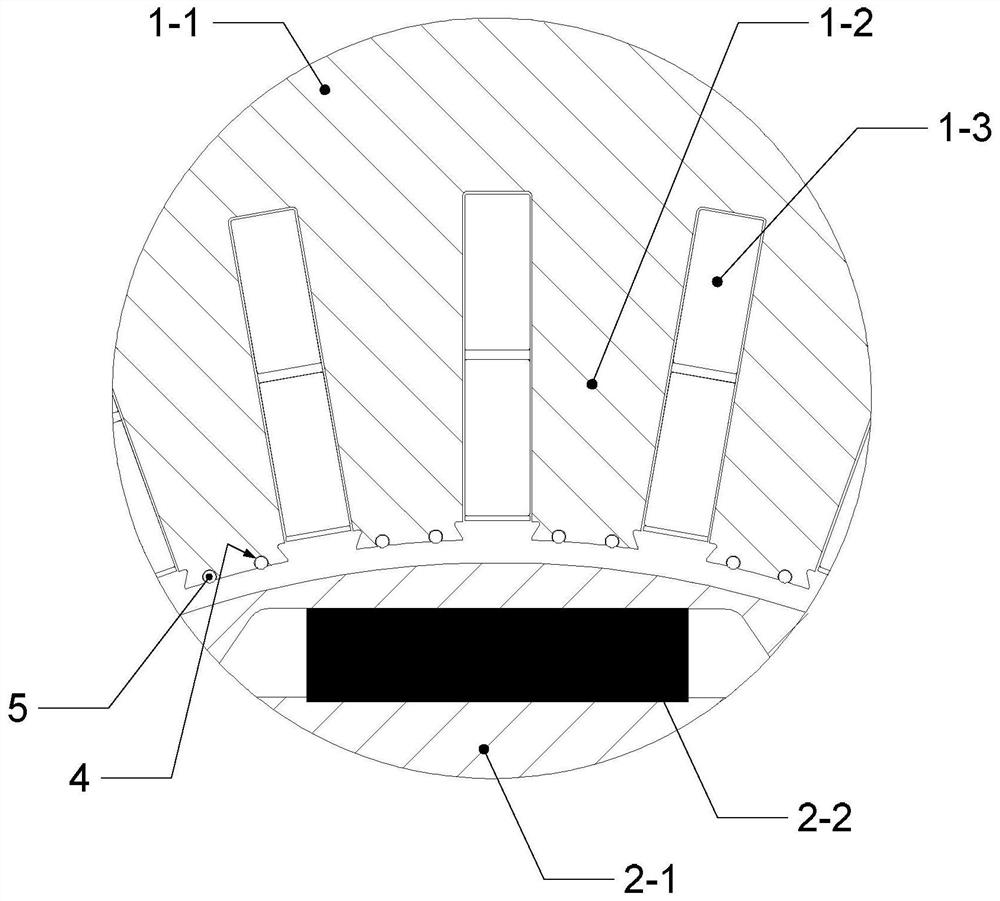

[0022] The stator 1 includes a stator core 1-1, a stator tooth 1-2 and a stator winding 1-3. The inner surface of the stator core 1-1 is uniformly distributed with 2N stator teeth 1-2 along the circumferential direction, and between two adjacent stator teeth 1-2 The stator windings 1-3 are arranged in the stator slots formed between them;

[0023] The rotor 2 includes a rotor core 2-1 and a permanent magnetic pole 2-2. The rotor core 2-1 is embedded with 2P permanent magnetic poles 2-2 along the circumferential direction. The pe...

specific Embodiment approach 2

[0036] Specific Embodiment 2: This embodiment further explains Embodiment 1, and fan-shaped oblique ventilation slots 2-3 are also provided, and 2P fan-shaped oblique ventilation slots 2-3 are evenly distributed along the circumferential direction of the rotor core 2-1. The ventilation slot 2 - 3 is an axial slot passing through the rotor core, and is located between the permanent magnet pole 2 - 2 and the rotating shaft 3 .

[0037] The fan-shaped oblique ventilation slots 2-3 are axially inclined.

[0038] The stator can dissipate heat with the help of water channels in the casing, but it is difficult for the rotor to dissipate heat. Usually, there are axial ventilation slots parallel to the rotating shaft on the rotor body, but the heat dissipation effect is not good. Opening oblique ventilation grooves not only saves materials and reduces the moment of inertia, but also improves the heat dissipation effect of the rotor and effectively reduces the temperature of the rotor.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com