Vamp with multilayer structure and shoe with vamp

A technology of multi-layer structure and upper, which is applied to shoe uppers, footwear, boot legs, etc., can solve the problems of easy environmental pollution, high cost, and many processes, and achieves good protection and support, good coverage, and enhanced three-dimensional sense. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

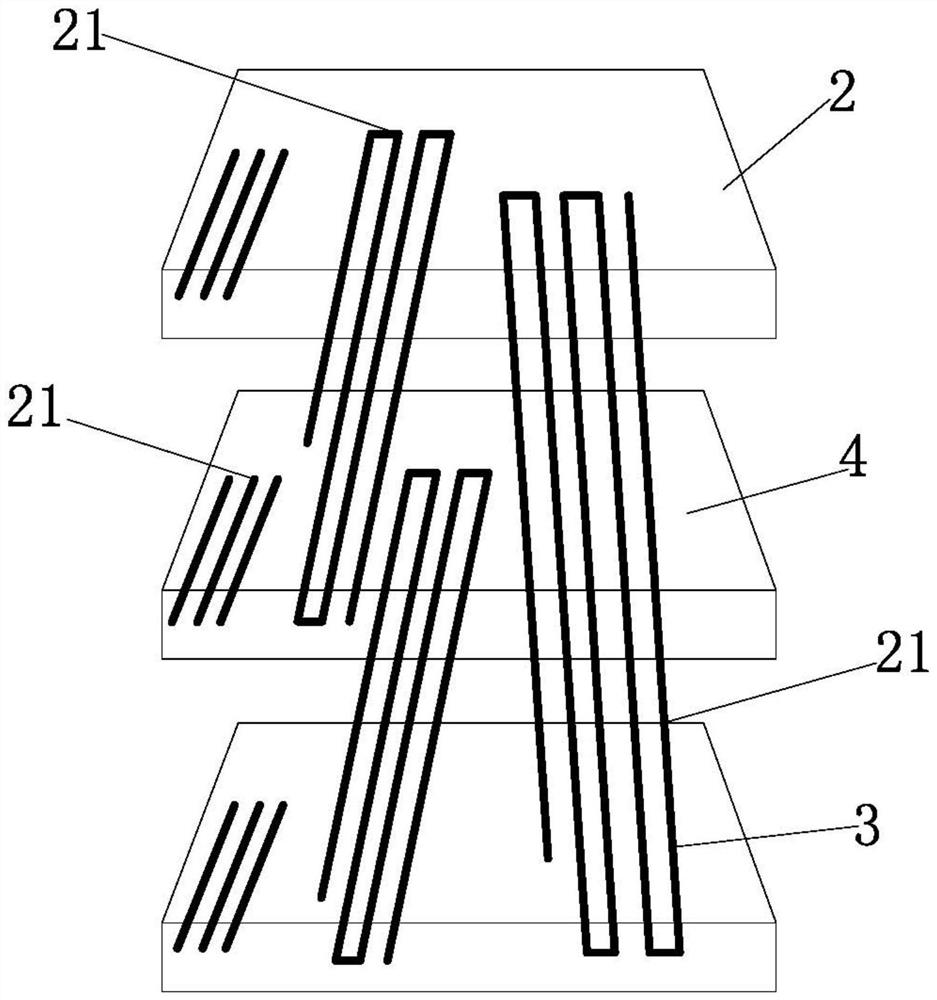

[0029] like Figure 1-2 As shown, a shoe upper 1 with a multi-layer structure includes a shoe upper 1, the shoe upper 1 includes a knitted component formed by integral knitting, and the knitted component includes a first knitted layer 2, which is arranged on the first knitted layer 2. Below the second braided layer 3 , an intermediate gap layer 4 for connecting the first braided layer 2 and the second braided layer 3 is provided between the first braided layer 2 and the second braided layer 3 .

[0030] The first woven layer 2 is woven with a first jacquard structure 21 having a regular or irregular jacquard pattern.

[0031] The weaving method of the first jacquard structure 21 can be weaving in the first weaving layer 2;

[0032] The weaving method of the first jacquard structure 21 may be weaving in the intermediate gap layer 4;

[0033] The weaving method of the first jacquard structure 21 can be weaving on the second weaving layer 3;

[0034] The weaving method of the ...

Embodiment 2

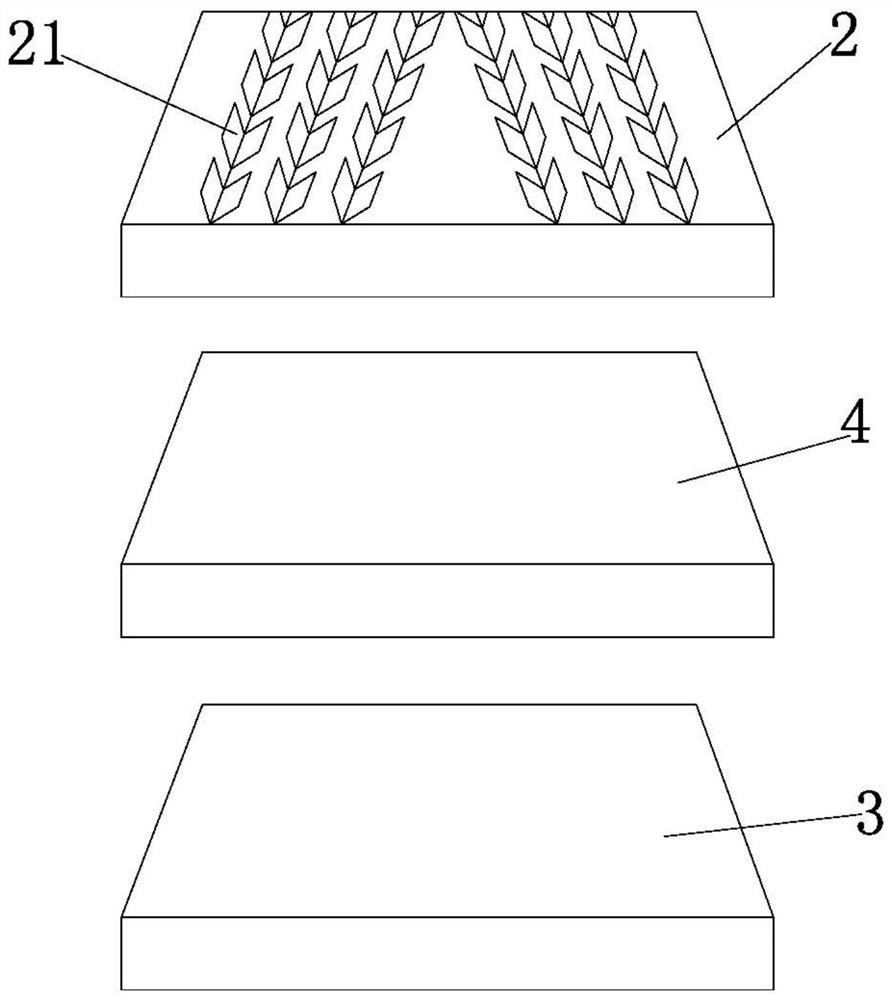

[0042] like Figure 3-4 As shown, a shoe upper with a multi-layer structure includes a shoe upper 1, and the shoe upper 1 includes a knitted component formed by integral knitting, and the knitted component includes a first knitted layer 2 arranged below the first knitted layer 2. The second braided layer 3 is provided with an intermediate gap layer 4 between the first braided layer 2 and the second braided layer 3 for connecting the first braided layer 2 and the second braided layer 3 .

[0043] The first woven layer 2 is woven with a first jacquard structure 21 having a regular or irregular jacquard pattern.

[0044] The intermediate gap layer 4 is woven with a third jacquard structure 41 having a regular or irregular jacquard pattern.

[0045] The weaving method of the first jacquard structure 21 can be weaving in the first weaving layer 2;

[0046] The weaving method of the first jacquard structure 21 may be weaving in the intermediate gap layer 4;

[0047] The weaving m...

Embodiment 3

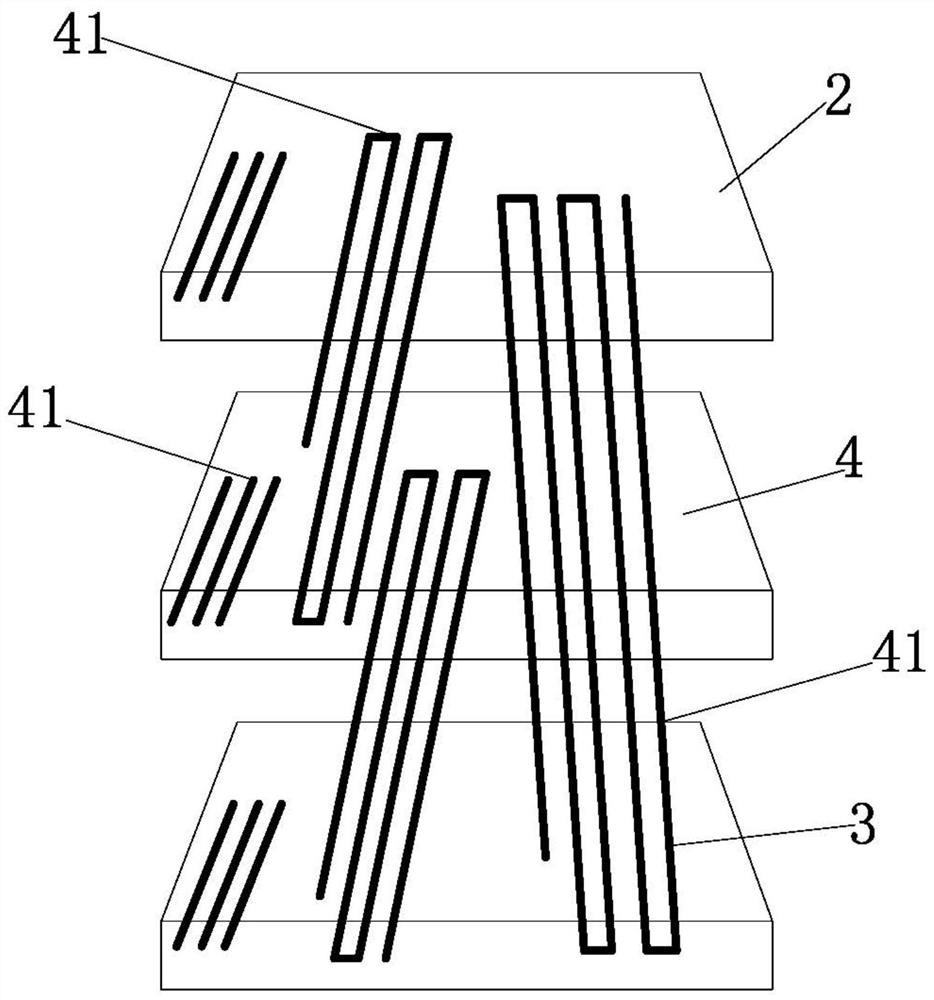

[0062] like Figure 5-6 As shown, a shoe upper with a multi-layer structure includes a shoe upper 1, and the shoe upper 1 includes a knitted component formed by integral knitting, and the knitted component includes a first knitted layer 2 arranged below the first knitted layer 2. The second braided layer 3 is provided with an intermediate gap layer 4 between the first braided layer 2 and the second braided layer 3 for connecting the first braided layer 2 and the second braided layer 3 .

[0063] The first woven layer 2 is woven with a first jacquard structure 21 having a regular or irregular jacquard pattern.

[0064] The second woven layer 3 is woven with a second jacquard structure 31 having a regular or irregular jacquard pattern.

[0065] The intermediate gap layer 4 is woven with a third jacquard structure 41 having a regular or irregular jacquard pattern.

[0066] The weaving method of the first jacquard structure 21 can be weaving in the first weaving layer 2;

[006...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap