Pickled Chinese cabbage sauce mixing stirrer

A technology for mixers and sauces, which is applied to mixers, mixer accessories, mixers with rotating mixing devices, etc., can solve the problem of material waste, insufficient mixing of sauerkraut sauce mixing and mixing devices, and easy adhesion of sauces to mixing barrels. Inner wall and other problems to achieve the effect of preventing adhesion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

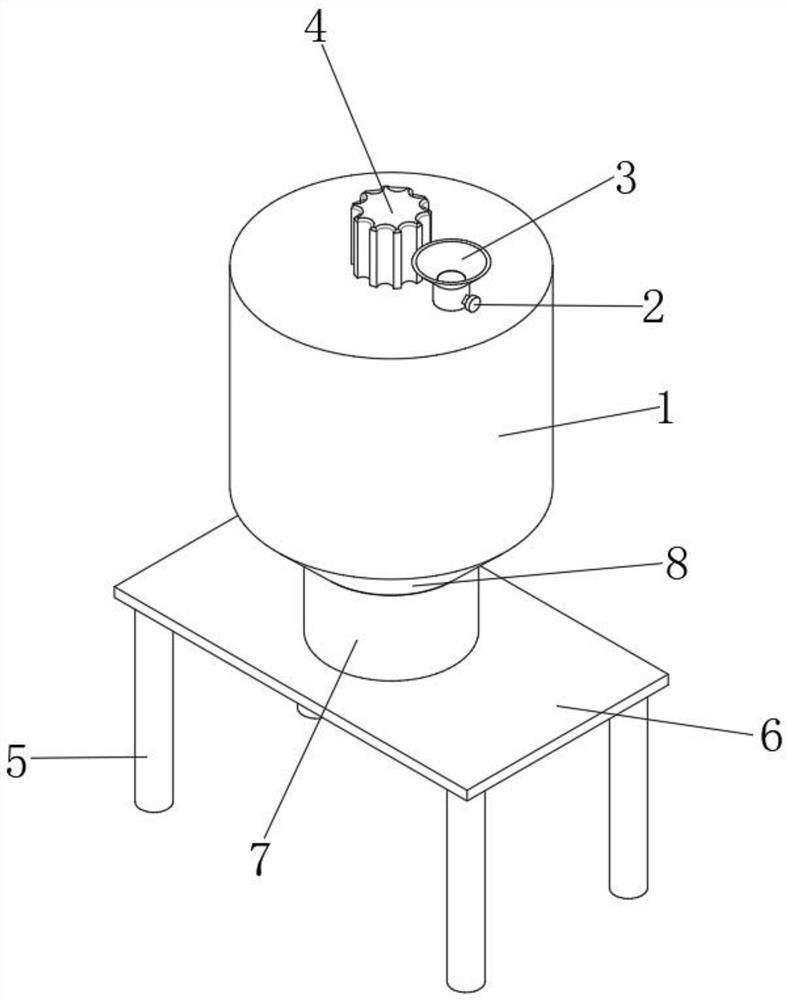

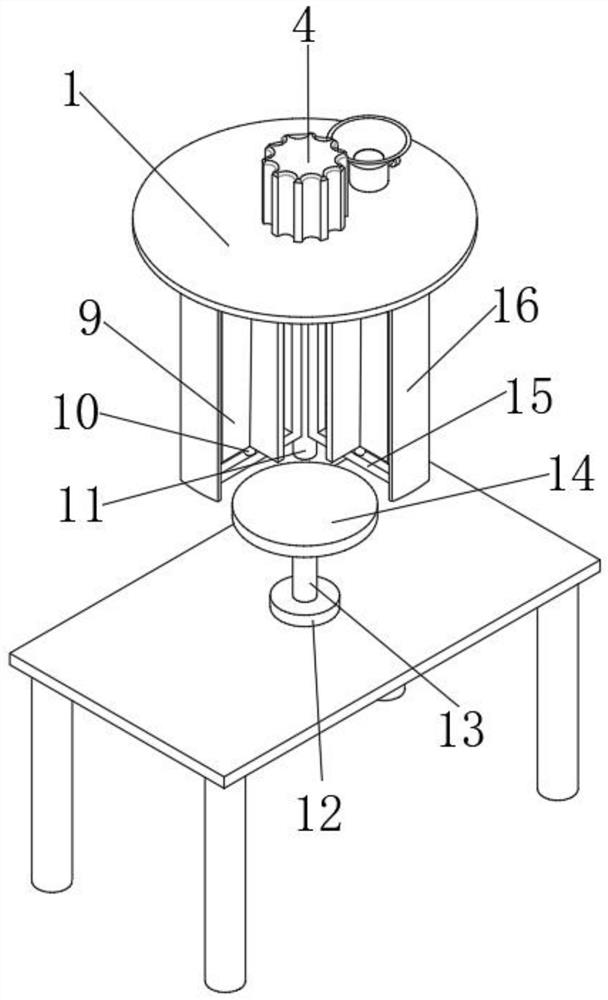

[0024] refer to Figure 1-3 , sauerkraut sauce mixing mixer, comprising a mixing tank 1, the top outer wall of the mixing tank 1 is connected with a rotating motor 4 by bolts, and the output shaft of the rotating motor 4 is connected with a first rotating shaft 11 through a coupling, and the circumference of the first rotating shaft 11 The outer wall is connected with a plurality of stirring blades 15 by bolts, and one side of the outer wall of the stirring blades 15 has a through hole, and the top inner wall and the bottom inner wall of the through hole are rotatably connected with the same second rotating shaft 10, and the circumference of the second rotating shaft 10 A plurality of stirring paddles 9 are connected to the outer wall by bolts, and a scraper 16 is connected to one side of the outer wall of the stirring blade 15 by bolts, and one side of the outer wall of the scraper 16 is attached to the circumferential inner wall of the mixing tank 1 .

[0025] In the present...

Embodiment 2

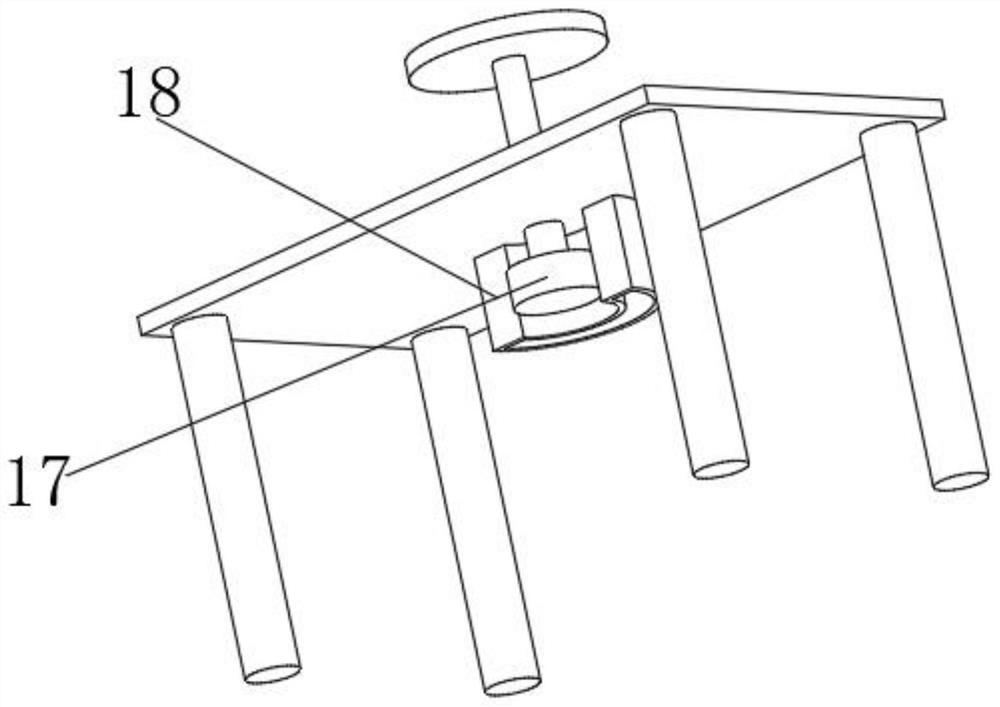

[0033] refer to Figure 4 , sauerkraut sauce mixing mixer, compared with embodiment 1, the top outer wall of support plate 6 is connected with cleaning liquid tank 20 by bolt, and one side outer wall of support plate 6 is connected with suction pump 21 by bolt, and suction pump 21 The liquid inlet pipe of the pump is connected with a liquid suction pipe extending into the cleaning liquid tank 20 through bolts, and the liquid discharge end of the liquid suction pump 21 is connected with a liquid discharge pipe extending into the mixing tank 1 through bolts, and the other end of the liquid discharge pipe A shower head 19 is connected by bolts.

[0034] During use, after the blanking is completed, the cleaning liquid is drawn into the mixing tank 1 by the liquid pump 21, and the stirring paddle 9 is driven by the rotating motor 4 to rotate, so as to clean the stirring paddle 9 and the stirring blade 15, and the scraper 16 rotates to The inner wall of the mixing tank 1 is cleaned...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com