Multifunctional novel welding table

A welding table, multi-functional technology, applied in welding equipment, auxiliary welding equipment, welding/cutting auxiliary equipment, etc., can solve problems such as single function, achieve the effect of protection device, low cost of transformation and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

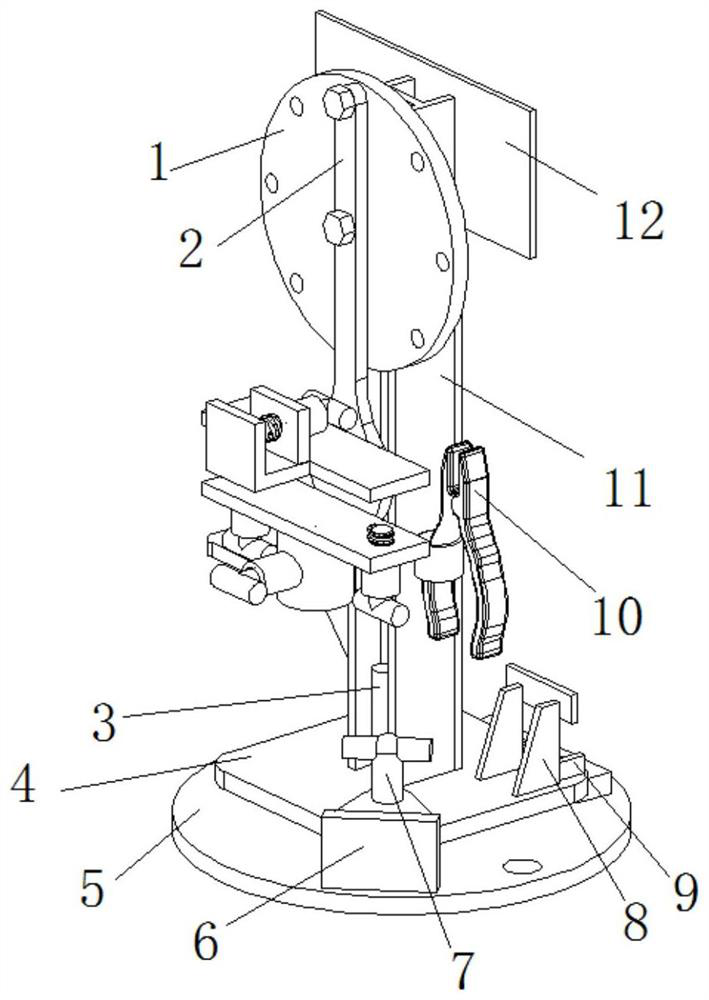

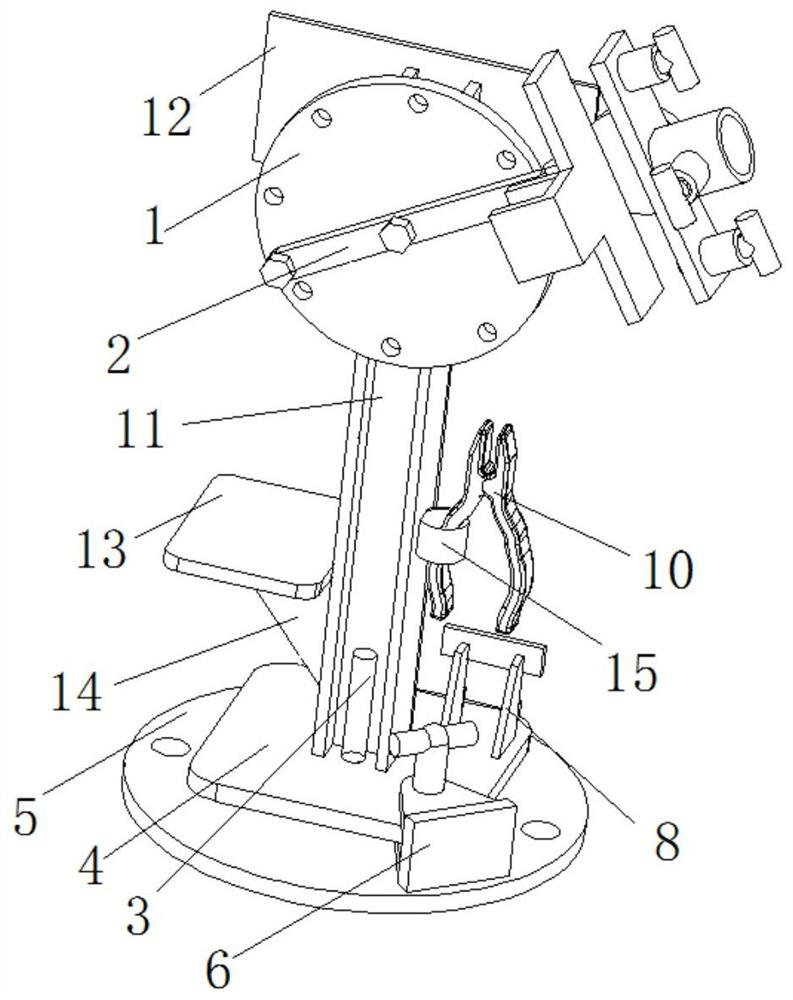

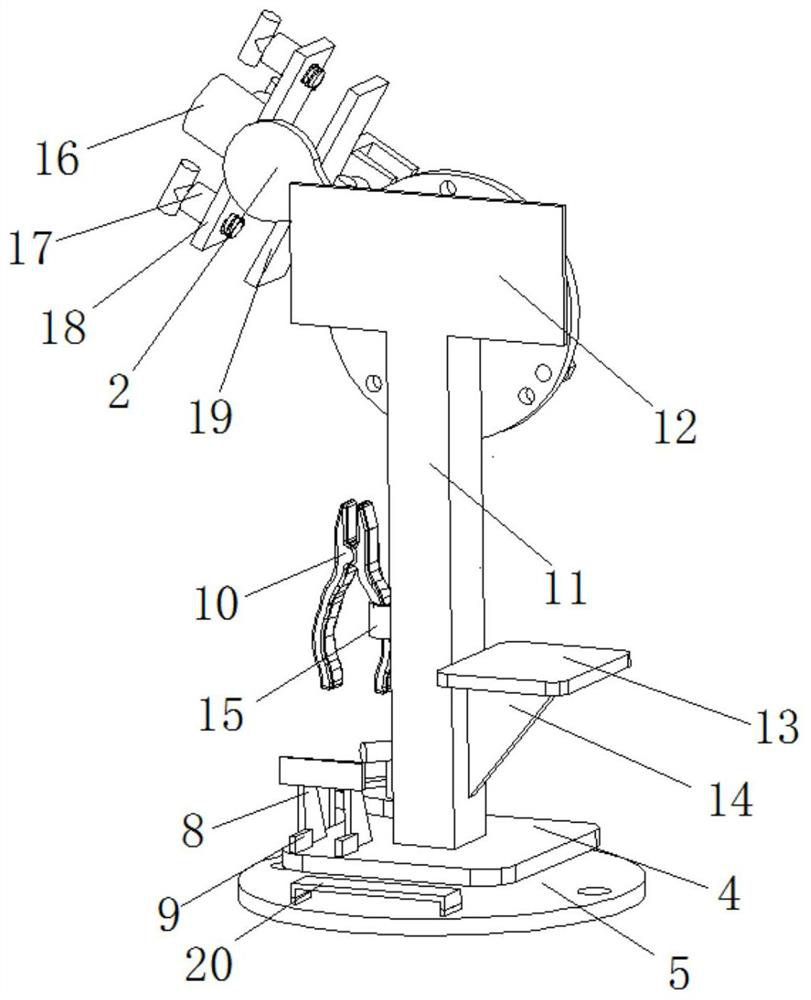

[0028] Example: During use, because the upper base plate 4 and the lower base plate 5 are in a rotary connection mode, the first working interface and the second working interface can be quickly switched by rotating the upper base plate 4, and the locking structure 6 Fix the upper base plate 4 and the lower base plate 5;

[0029] The welding parameters are adjusted by the test welding plate on the test welding area 20, and because the connecting magnet base is connected between the test welding plate and the lower bottom plate 5, the test point is fixed at the test welding area 20;

[0030] Place the weldment on the positioning block 9, assemble the fillet weld and flat butt test piece, the assembly time only takes 1 minute, which is extremely convenient and fast. After the spot welding is fixed, take out the workpiece and place it on the upper bottom plate 4 for flat welding;

[0031] Then firstly rotate the second working interface to the working point position, lock the upp...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The inside diameter of | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com