All-round lifting electric emergency repairing manned device

An electric emergency and lifting technology, which is applied in the direction of hoisting equipment safety devices, lifting devices, and vehicles used for freight transportation, can solve the problems of translation and rotation of lifting platforms, and achieves easy repair and maintenance, simple operation, simple and reliable principle Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

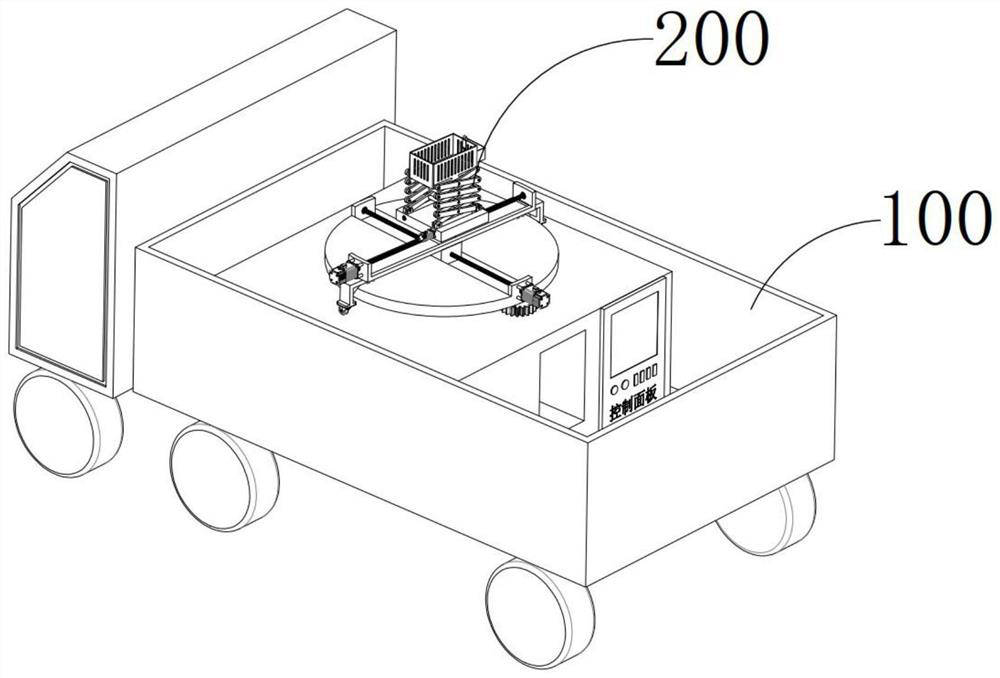

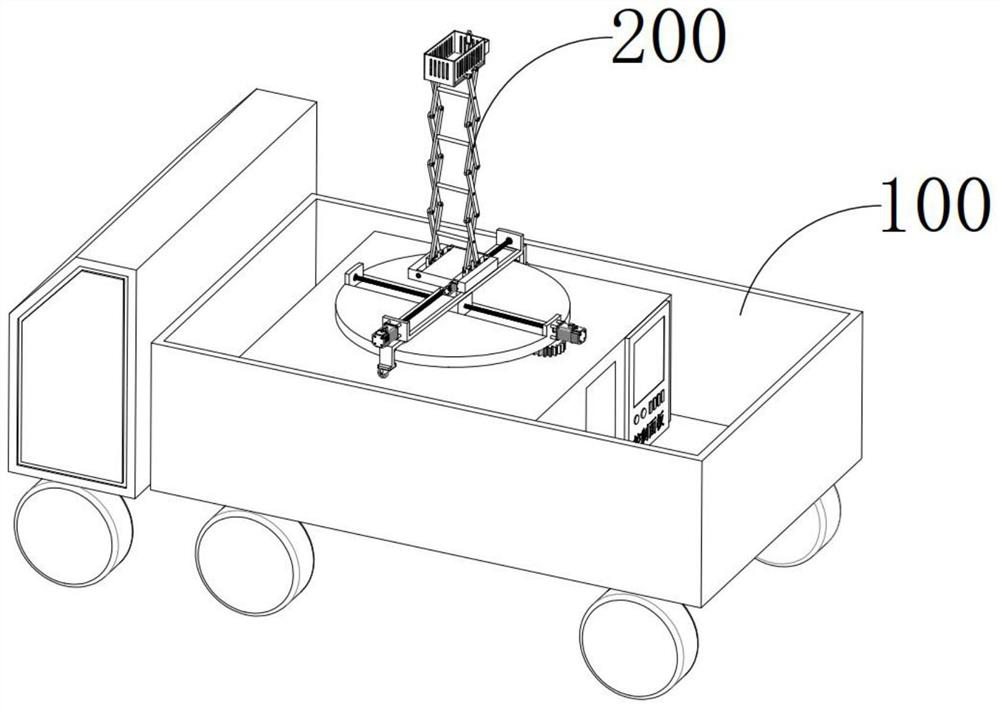

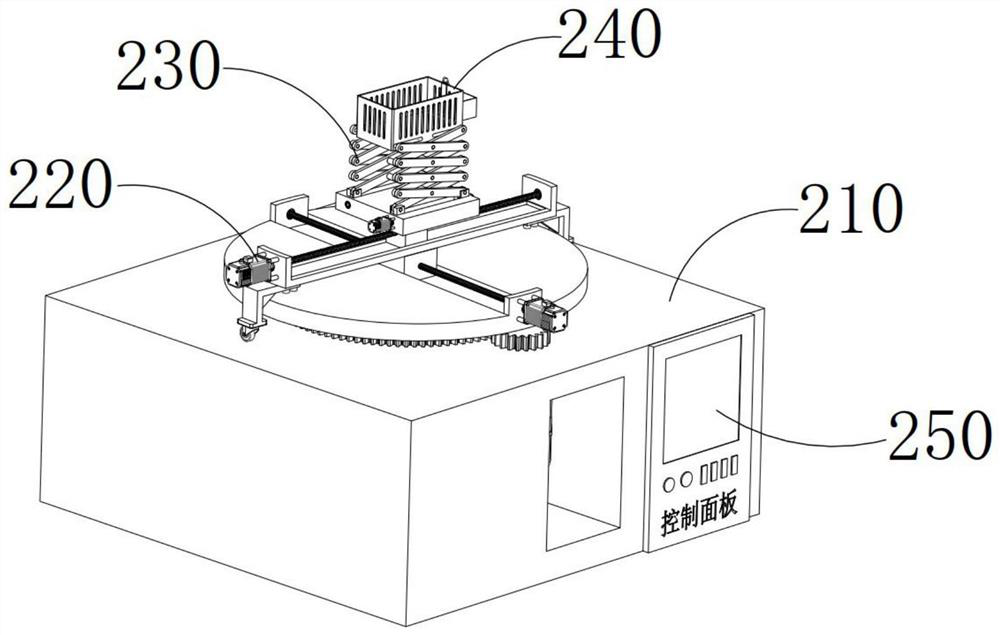

[0055] see Figure 1-18 , an all-round lift-type electric emergency repair manned equipment, which includes a construction vehicle 100 and a manned lifting device 200, the manned lifting device 200 is located in the compartment of the engineering vehicle 100, and the manned lifting device 200 includes sequentially arranged from bottom to top The rotary drive mechanism 210, the sliding drive mechanism 220, the connecting rod lifting mechanism 230, the manned lifting platform 240 and the control panel 250, the connecting rod lifting mechanism 230 can be extended and shortened and its top is connected with the manned lifting platform 240, and its bottom end is connected with the sliding driving mechanism 220, the sliding driving mechanism 220 can drive the connecting rod lifting mechanism 230 and the lifting table 240 to translate horizontally or vertically in the horizontal plane, and the rotating driving mechanism 210 can drive the sliding driving mechanism 220, the connecting r...

Embodiment 2

[0071] see Figure 12 , this embodiment is consistent with the other solutions disclosed in Embodiment 1, the only difference is that a rectangular toolbox 241 with an upward opening is installed outside the opening of the lifting table 240, and the middle position of one side of the opening of the toolbox 241 is The hook 242 formed by the continuous bending of the plate body is fixedly arranged and the opening of the hook 242 is vertically downward, and one end of the opening of the hook 242 is provided with a bent plate 243 arranged obliquely outwards. The distance between one side increases gradually from top to bottom in the vertical direction. The top of the hook 242 is fixedly provided with a ring-shaped wire handle 244. During use, the emergency repair tool is placed in the tool box 240, which saves lifting The space in the platform 240 is convenient for operators to move in the lifting platform 240.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com