Preparation method of CuFeSb thin film

A thin-film preparation and thin-film technology, which is applied in the field of CuFeSb thin-film preparation, can solve the problems of single control means and no obvious control effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

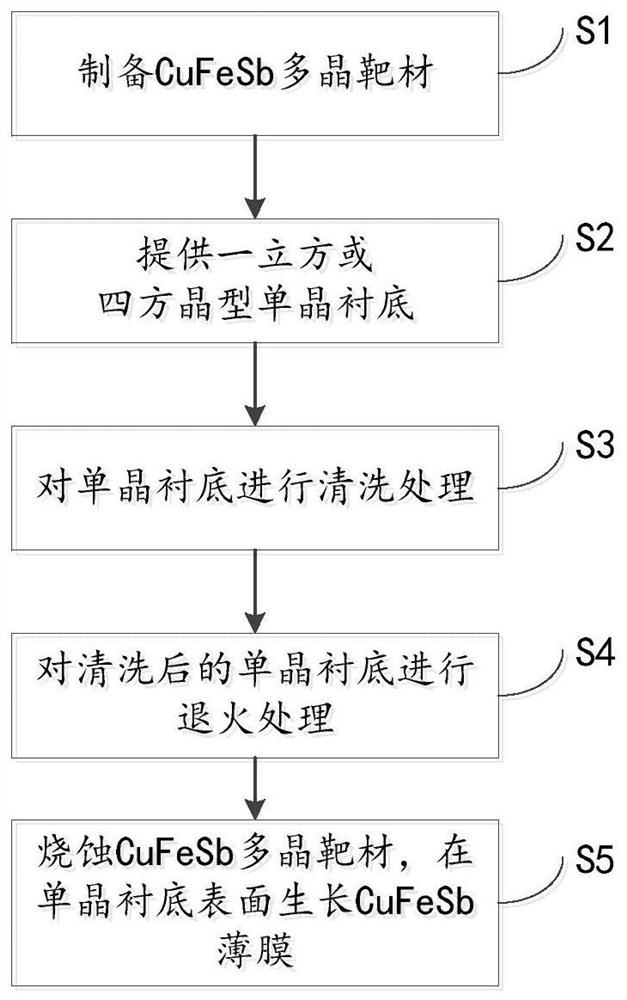

[0047] The embodiment of the present invention provides a kind of CuFeSb film preparation method, such as figure 1 As shown, the method includes the following steps:

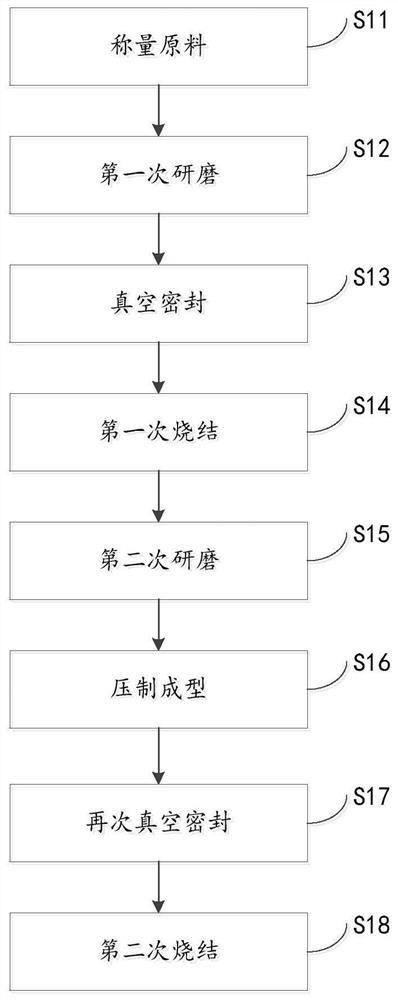

[0048] S1. Prepare CuFeSb polycrystalline target;

[0049] S2. Provide a cubic or tetragonal single crystal substrate;

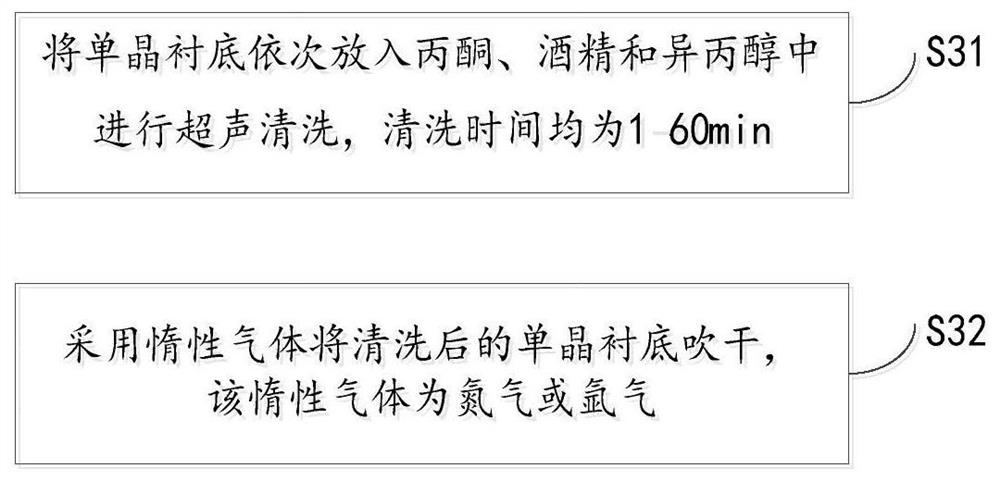

[0050] S3. Cleaning the single crystal substrate;

[0051] S4. Annealing the cleaned single crystal substrate;

[0052] S5. Ablating the CuFeSb polycrystalline target, and growing a CuFeSb thin film on the surface of the single crystal substrate.

[0053] In the embodiment of the present invention, the basic principle and process of using the pulsed laser deposition method to prepare thin films is that the focused laser beam interacts with the target to generate plasma, and the plasma is transported in space to form a highly oriented plume, which carries The high-energy particles condense on the substrate to form a thin film. Therefore, the acquisition of the target is the first step in t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com