A Milling and Grinding Device for Eliminating Arching Defects on Railway Sleepers

A railway rail, milling and grinding technology, applied in the directions of roads, tracks, laying tracks, etc., can solve the problems of low efficiency and high labor costs, and achieve the effect of flexible tool setting operation, reducing labor costs, and improving the accuracy of milling and grinding.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0070] The present invention will be described in detail below by way of a particular embodiment in order to further explain the present invention.

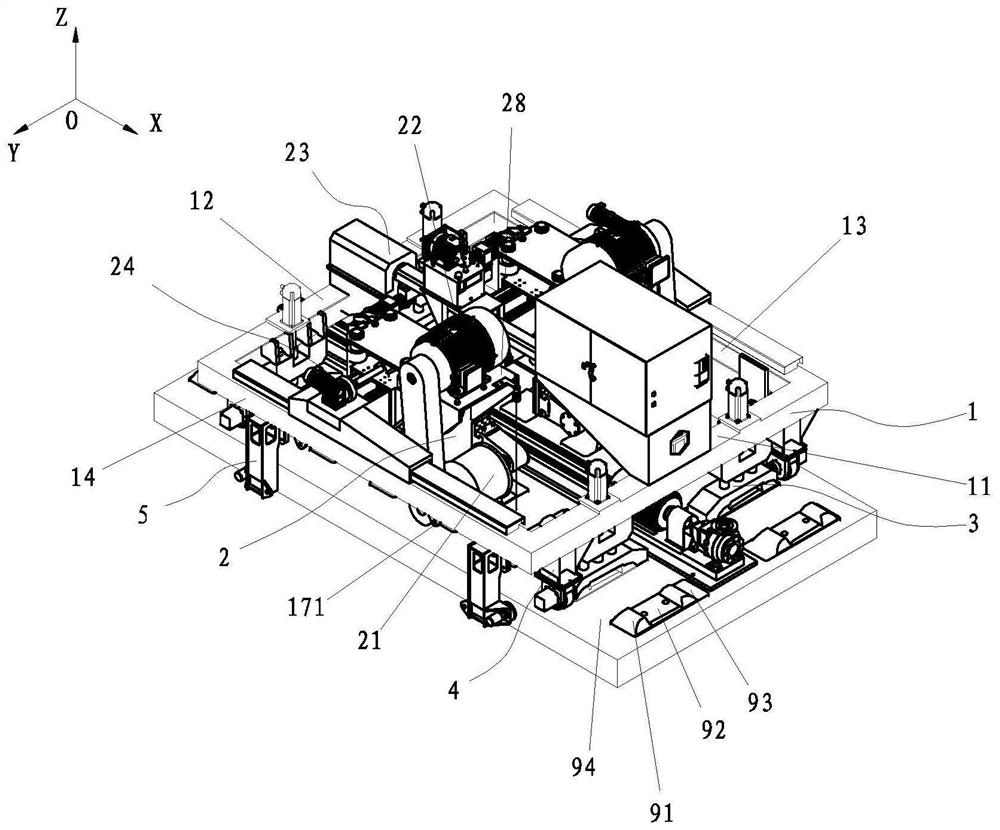

[0071] In the figure, the coordinate axes X, Y, and Z represent the front-rear direction of the present invention, the left-right direction, and the up and down direction, and the coordinate axis X is directed in the forward direction, the coordinate axis Y points to the right direction, the coordinate axis z is directed in the upper direction, the coordinate axis X, Y The intersection of z is O point.

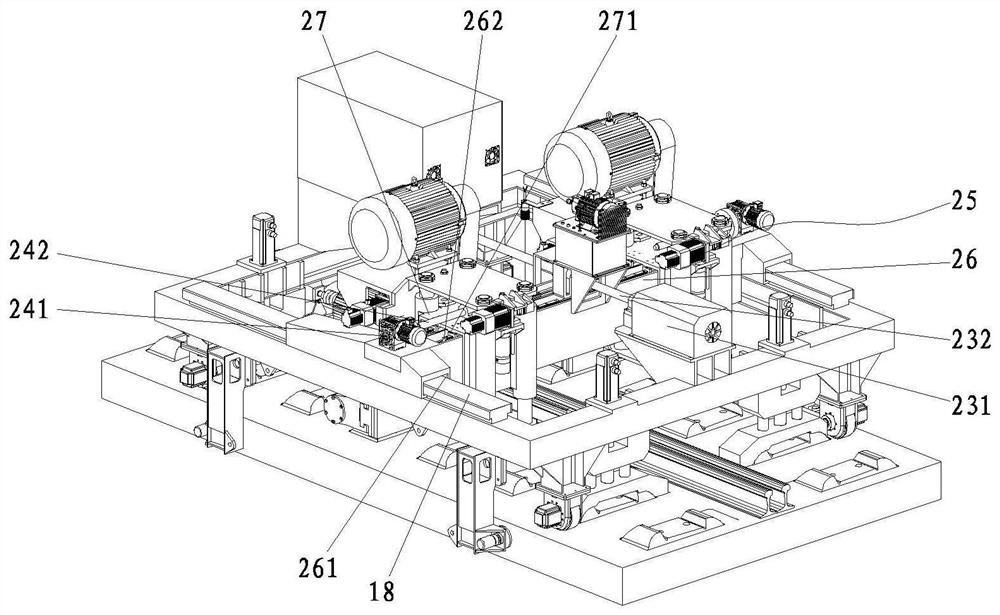

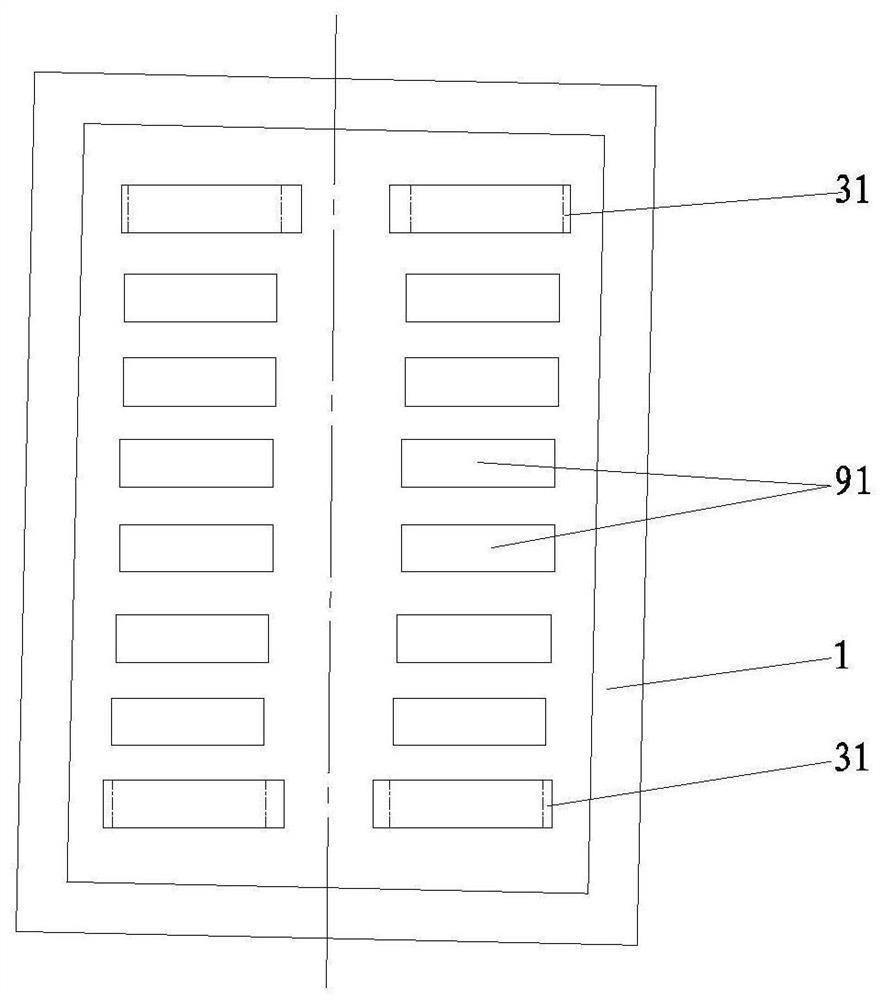

[0072] Such as Figure 1-13 As shown, a milling apparatus that eliminates the rolling of the railway pillow, wherein the processed cutter head 21 that milling the sleeper is rotated, the tool head rotating the drive device 22 drives the machining cutter head, and the drive processing cutter head moves. Tarn head motion drive mechanism. Also includes the moving frame 1, the moving frame 1 is a rectangular frame structure, including a f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com