Multi-layer sliding zone landslide and slide-resistant pile model test system and method

A model test, anti-sliding pile technology, applied in the test of foundation structure, construction, foundation structure engineering, etc., can solve the problems of large size, non-sliding pile and surrounding soil real-time monitoring, complex control system, etc. Moderate size, overcoming the effects of long production cycle and high data accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] In order to make the purpose, technical solution and advantages of the present invention clearer, the embodiments of the present invention will be further described below in conjunction with the accompanying drawings.

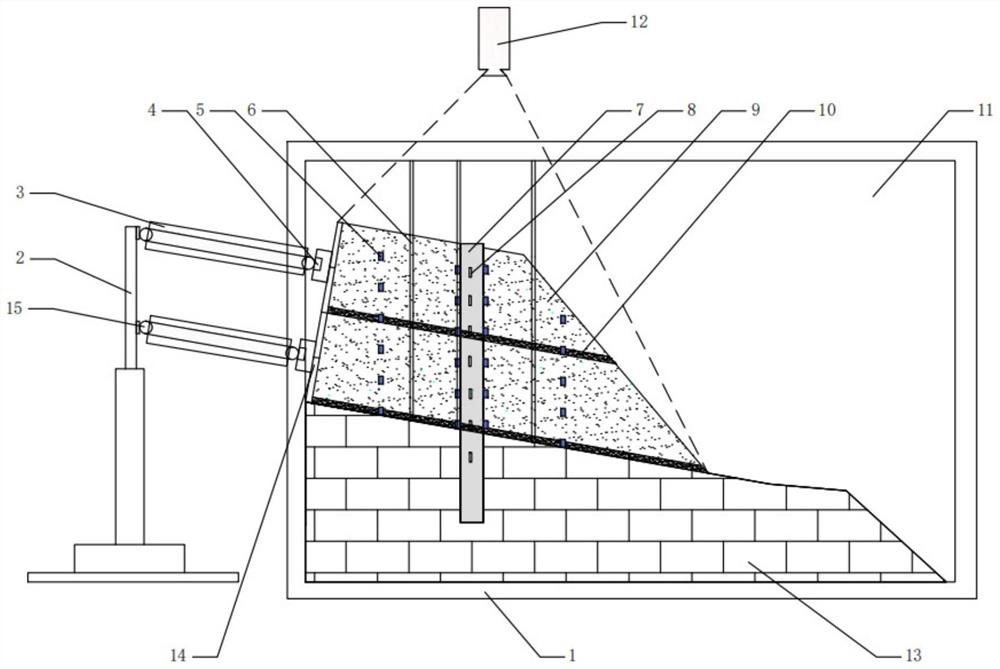

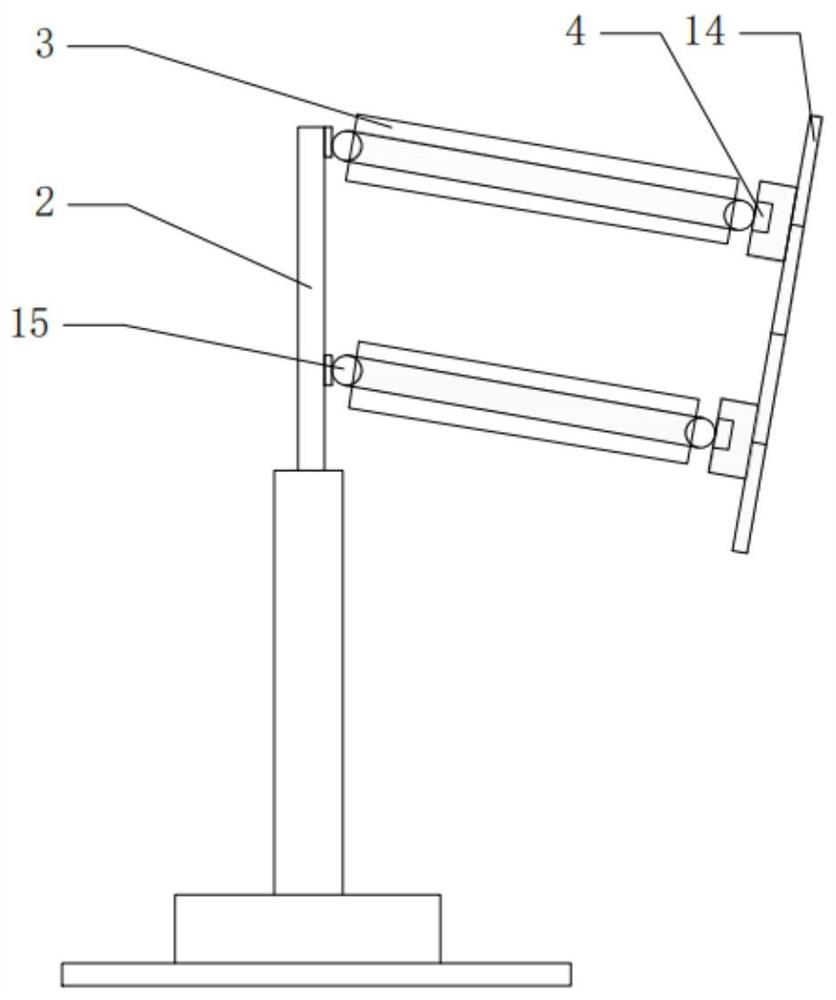

[0033] Please refer to figure 1 , the embodiment of the present invention provides a multilayer slide belt landslide-anti-slide pile model test system, including a model box 1, an active loading device and a landslide monitoring device.

[0034] Specifically, the model box 1 in this embodiment is a rectangular box with openings at its front end, rear end and upper end. In order to facilitate the observation of the test situation in the model box 1, the left and right sides of the model box 1 are set as clear tempered glass baffles, which can be accurately controlled for real-time monitoring of the test situation in the model box 1 on the side. The slope surface shape of the landslide, the distribution and shape of the sliding body, the sliding zone and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com