Chain drive mechanism

A chain transmission mechanism and chain technology, applied in transmission devices, belts/chains/gears, mechanical equipment, etc., can solve torque transmission blockage, disengagement, and inability to maintain the first engaging part 8 and the second engaging part 9 Problems such as the snapping state, to achieve the effect of suppressing the impact sound and reducing the cost of raw materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] Next, a chain transmission mechanism according to an embodiment of the present invention will be described based on the drawings.

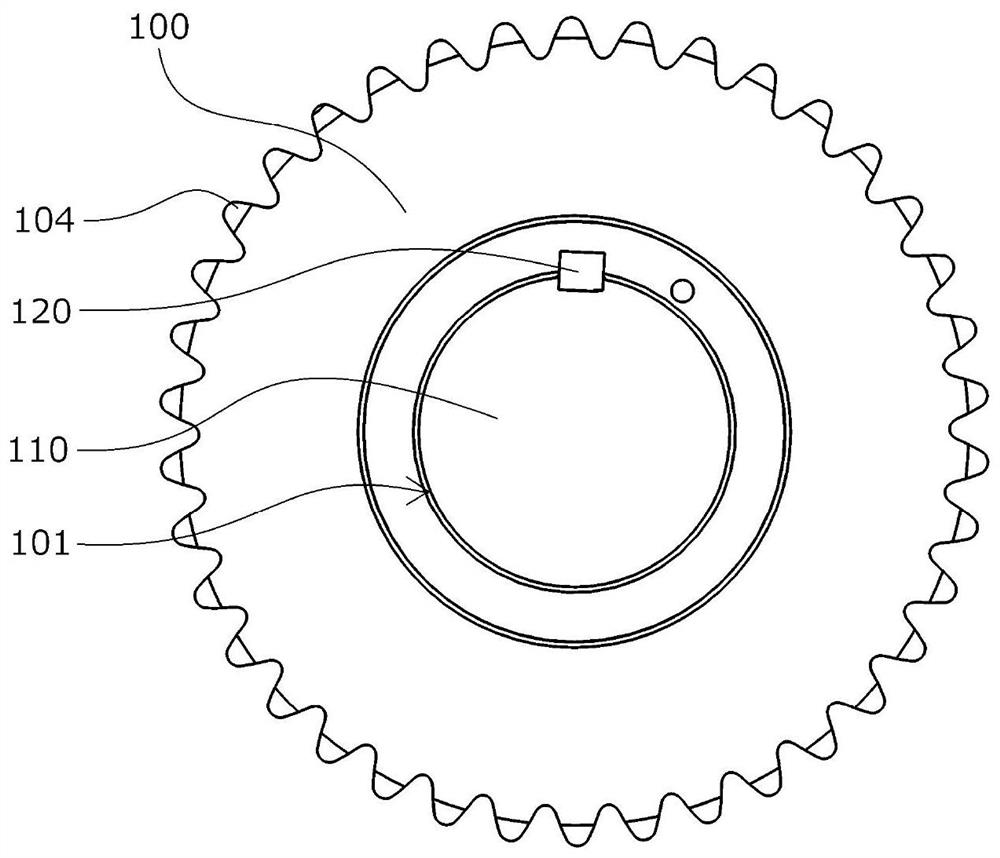

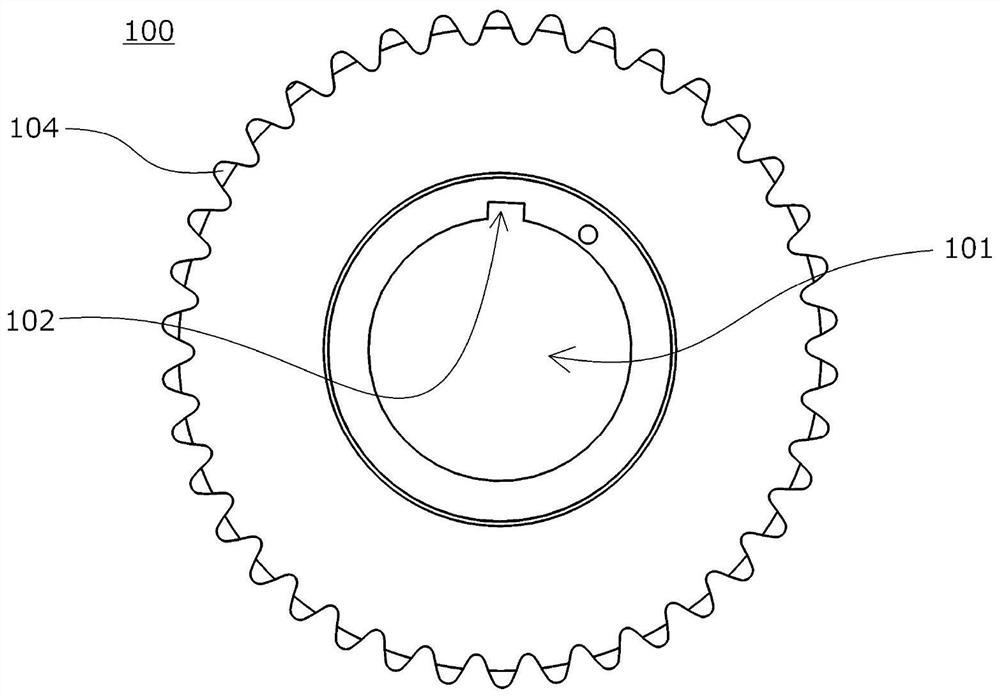

[0041] Such as Figure 1 to Figure 3 As shown, the chain transmission mechanism which is an embodiment of the present invention has a rotating shaft 110 , a sprocket 100 having a shaft hole 101 pierced by the rotating shaft 110 , and a chain (not shown) wound around the sprocket 100 .

[0042] On the inner peripheral surface of the shaft hole 101 , a groove-shaped rotation transmission groove 102 is provided along the opening direction of the shaft hole 101 .

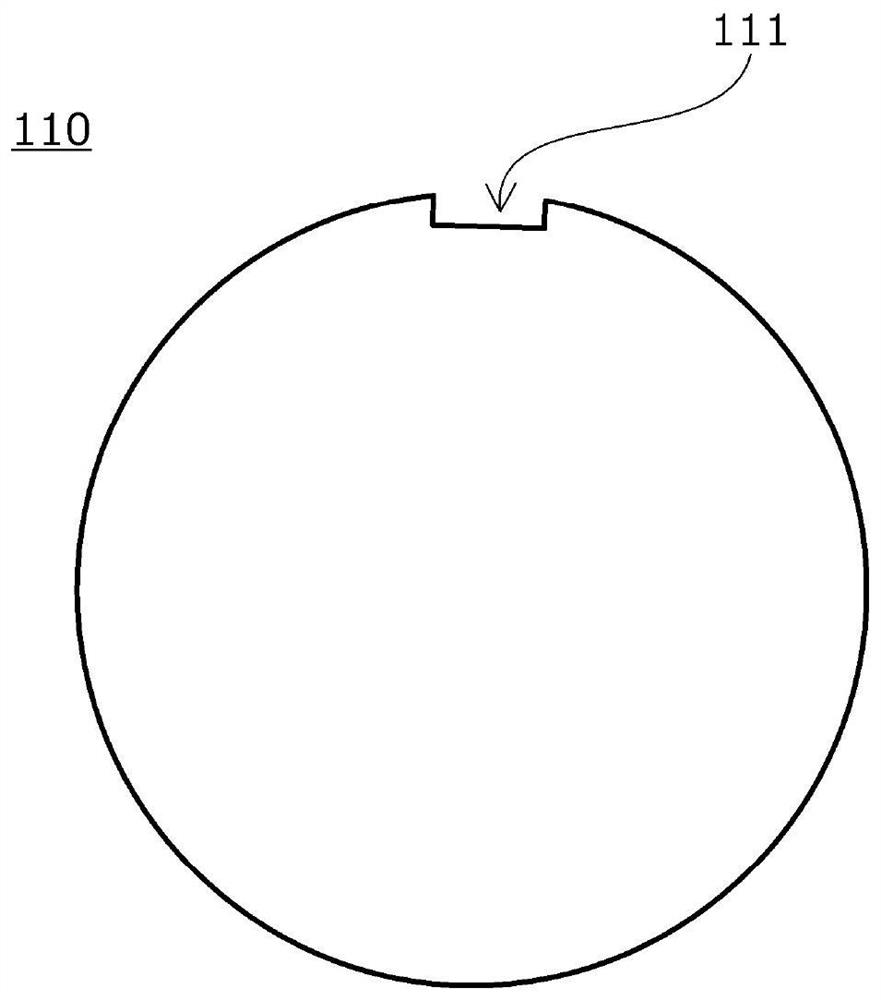

[0043] On the outer peripheral surface of the rotating shaft 110 , a groove-shaped receiving groove 111 is provided along the central axis of the rotating shaft 110 , and the receiving groove 111 and the rotation transmission groove 102 are formed to have equal circumferential widths.

[0044] In the receiving groove 111, a rotation transmission member 120 made of an elastic member ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com