Compact type multi-stage series PCHE heat exchanger and heat exchange method

A heat exchanger, compact technology, applied in the field of compact multi-stage series PCHE heat exchanger and heat exchange, can solve the problems of large space occupation, low utilization rate of heat exchanger space, multiple heat exchangers, etc., to achieve reduction Small direct heat transfer, effect of mitigating thermal stress problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

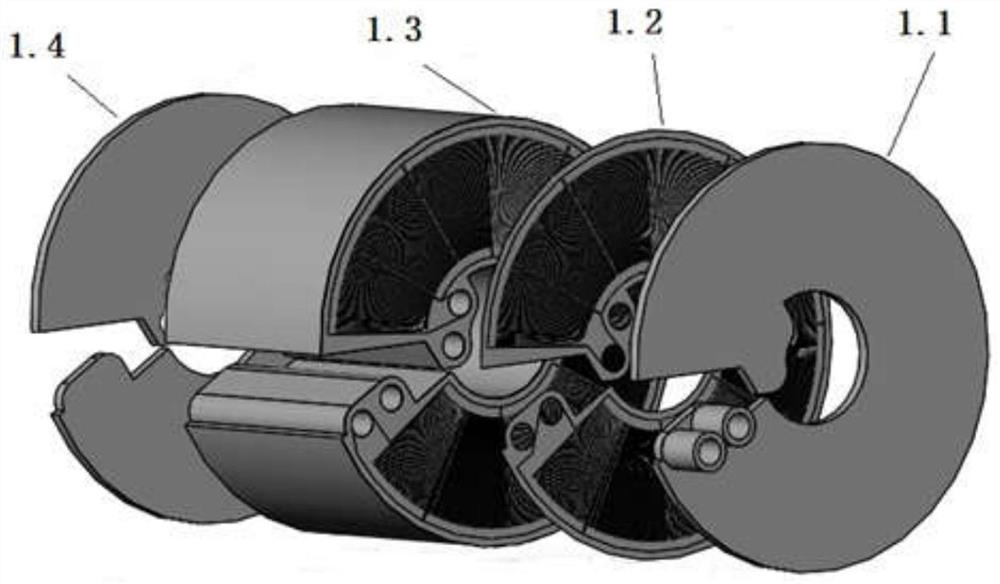

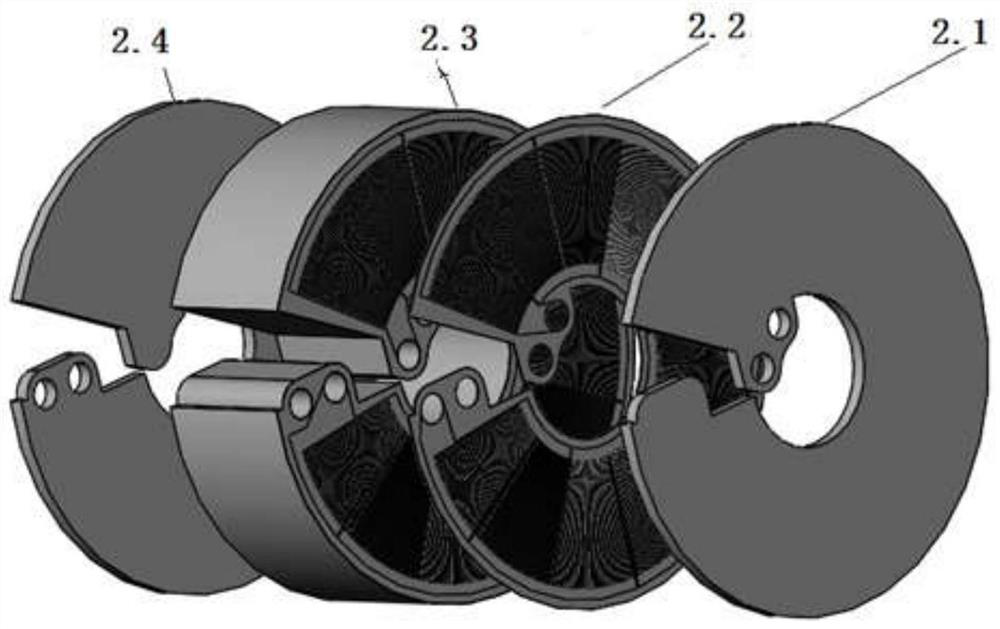

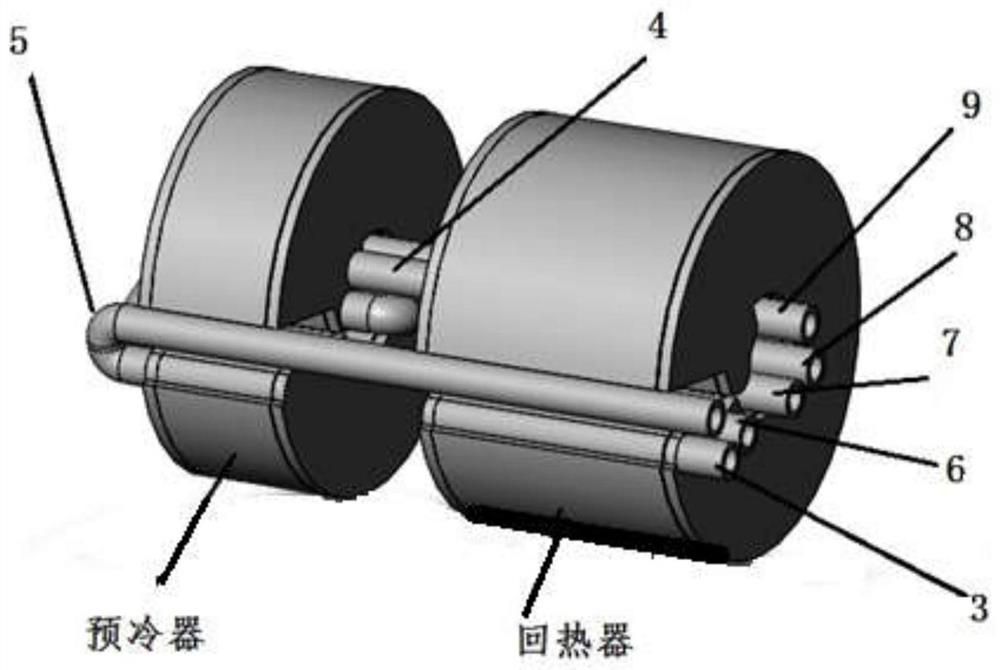

[0033] Such as figure 1 , figure 2 with image 3 As shown, the present invention is a compact multi-stage series PCHE heat exchanger. The heat exchanger system can realize the functions of the regenerator and precooler in the supercritical CO2 power generation system, and the whole is cylindrical. The system includes a regenerator Heater, precooler, inlet and outlet pipes and connecting pipes; the regenerator includes a regenerator front cover plate 1.1 welded and connected as a whole from front to back, several regenerator cold medium plates 1.2, and several regenerator The heat medium plate 1.3 of the precooler and the rear cover plate 1.4 of the regenerator. The cold medium plate 2.3 of the cooler and the rear cover plate 2.4 of the precooler, the inlet and outlet pipes include the inlet pipe 3 on the hot side of the regenerato...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com