Heat exchanger structure optimization method based on hot melt type gas-liquid double-phase heat exchange structure

A technology of heat exchange structure and optimization method, applied in design optimization/simulation, instruments, special data processing applications, etc., to achieve the effect of increasing heat transfer area, improving heat exchange efficiency, and reducing weight

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

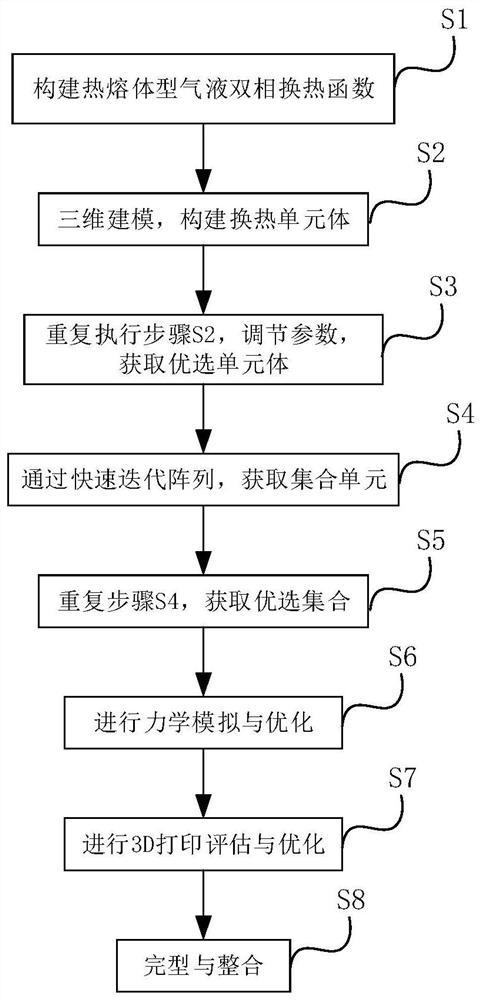

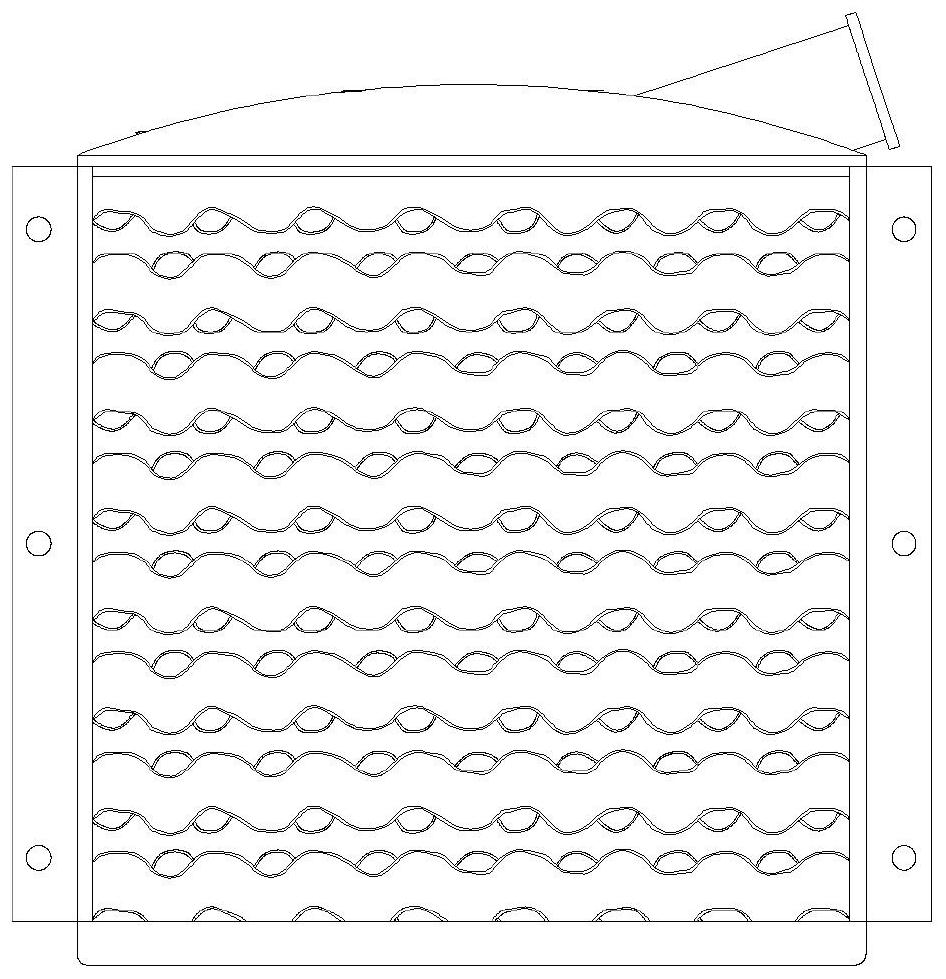

[0046] Such as figure 2 As shown, this embodiment provides a heat exchanger structure optimization method based on a hot-melt type gas-liquid two-phase heat exchange structure. The type gas-liquid two-phase heat transfer parameters are used as the main control to achieve heat dissipation efficiency and weight reduction of the overall radiator, including the following steps:

[0047] S1: According to the heat-melt type gas-liquid two-phase heat transfer structure, based on the sine and cosine functions, construct the hot-melt type gas-liquid two-phase heat transfer function;

[0048] It is equivalent to analyzing the mathematical principles of heat transfer in existing designs, conducting an in-depth analysis of the gas-liquid two-phase composition structure contained in the existing heat transfer structure, and cooperating with the means of additive manufacturing, and obtained the basic hot-melt type gas-liquid Two-phase heat transfer function construction strategy. Through...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com