A method for bonding multiple materials of large graphite heating elements used in the production of vacuum induction furnaces

A vacuum induction furnace and bonding method technology, applied in bonding methods, heating element materials, furnaces, etc., can solve the problems of low yield, high sales price, curb production and research and development, etc., and achieve the effect of high yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] (1) Preparation of high temperature graphite glue

[0029] High temperature graphite glue is mixed with cementing agent and cementing powder;

[0030] The binder is composed of 20wt% furfuryl alcohol (molecular formula: C 5 H 6 O 2 ), 80wt% tall acid TEA salt composition;

[0031] The cementitious powder is composed of 10wt% superconducting carbon black and 90wt% ultrafine artificial graphite powder;

[0032] When using, mix the cementing agent with 100-mesh-1000-mesh cement powder according to the mass ratio of 1:80 to prepare a paste, ready for use;

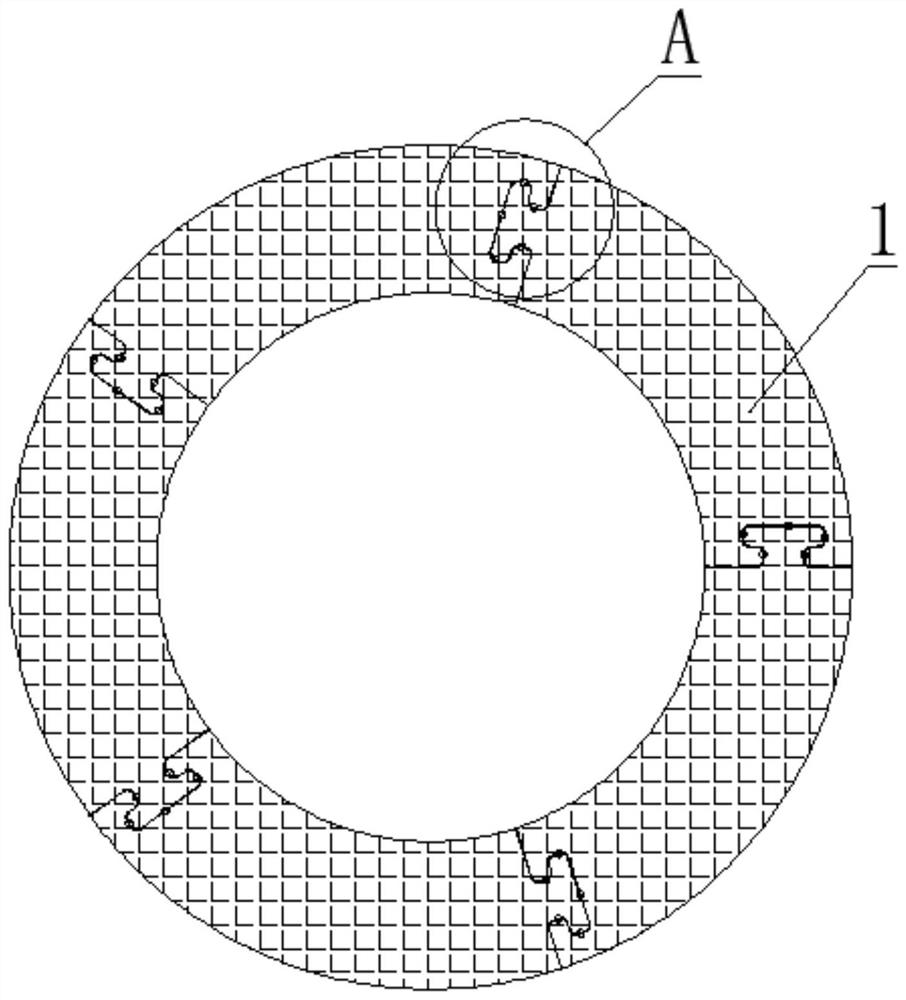

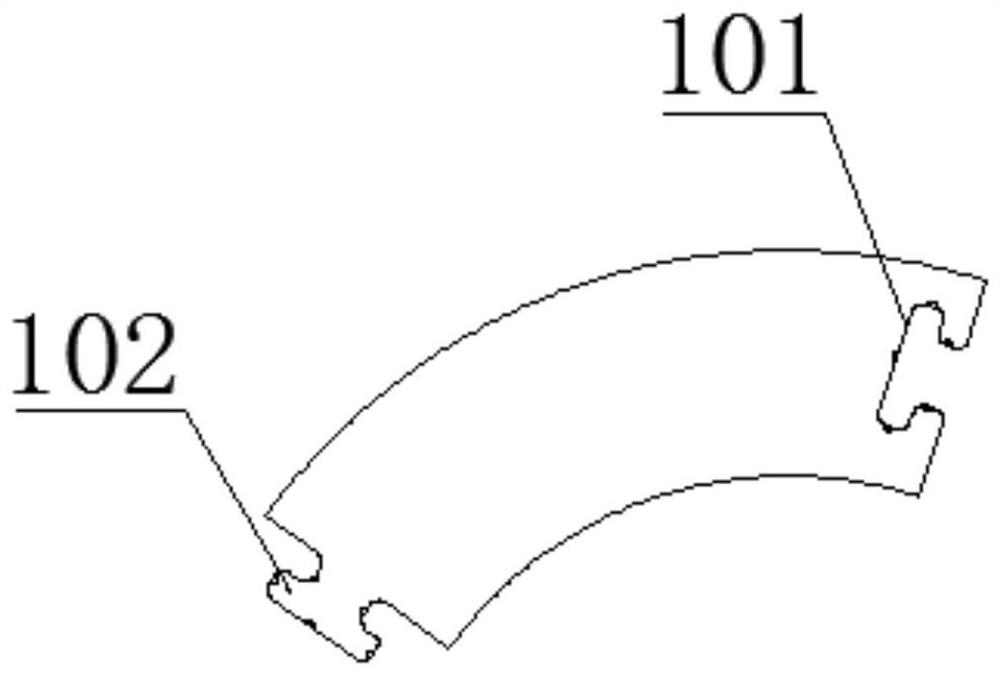

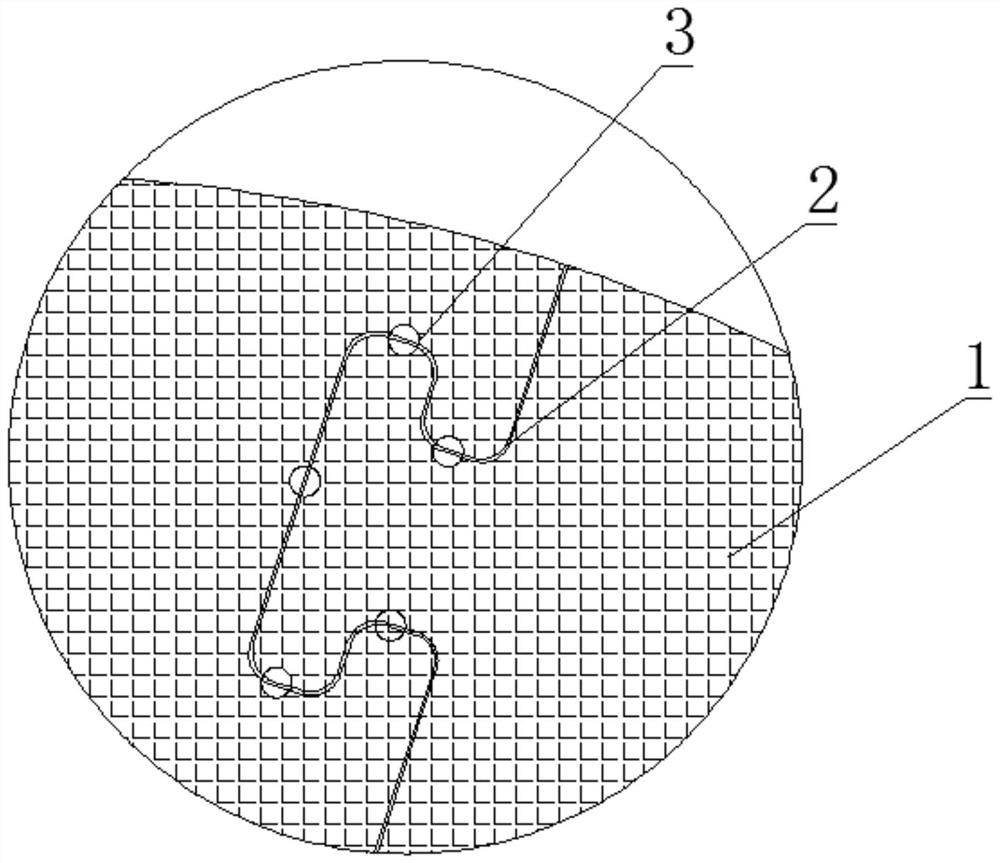

[0033] (2) Processing and splicing graphite heating element

[0034] a. According to the size of the large graphite heating body, 5 graphite blocks 1 are spliced together, and the size of the graphite blocks 1 is the same. The diameter of the large graphite heating body is 2000mm, and the two end faces of each graphite block 1 are respectively provided with The "T"-shaped bosses 102 and the "T"-shaped card slots ...

Embodiment 2

[0037] (1) Preparation of high temperature graphite glue

[0038] High temperature graphite glue is mixed with cementing agent and cementing powder;

[0039] The adhesive is made of 80wt% furfuryl alcohol (molecular formula: C 5 H 6 O 2 ), 20wt% tall acid TEA salt composition;

[0040] The cementitious powder is composed of 20wt% superconducting carbon black and 80wt% ultrafine artificial graphite powder;

[0041] When in use, mix the cementing agent and the 100-mesh-1000-mesh cement powder according to the mass ratio of 1:15 to prepare a paste, ready for use;

[0042] (2) Processing and splicing graphite heating element

[0043] a. According to the size of the large graphite heating body, 5 graphite blocks 1 are spliced together, and the size of the graphite blocks 1 is the same. The diameter of the large graphite heating body is 2000mm, and the two end faces of each graphite block 1 are respectively provided with The "T"-shaped bosses 102 and the "T"-shaped card slot...

Embodiment 3

[0046] (1) Preparation of high temperature graphite glue

[0047] High temperature graphite glue is mixed with cementing agent and cementing powder;

[0048]The binder is composed of 60wt% furfuryl alcohol (molecular formula: C 5 H 6 O 2 ), 40wt% tall acid TEA salt composition;

[0049] The cementitious powder is composed of 40wt% superconducting carbon black and 60wt% ultrafine artificial graphite powder;

[0050] When in use, mix the cementing agent and the 100-mesh-1000-mesh cement powder according to the mass ratio of 1:50 to prepare a paste, ready for use;

[0051] (2) Processing and splicing graphite heating element

[0052] a. According to the size of the large graphite heating body, 5 graphite blocks 1 are spliced together, and the size of the graphite blocks 1 is the same. The diameter of the large graphite heating body is 2000mm, and the two end faces of each graphite block 1 are respectively provided with The "T"-shaped bosses 102 and the "T"-shaped card slo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com