Automatic-temperature-control electrothermal coating for ice removal and prevention of railway vehicles, and preparation method and application thereof

A technology for electrothermal coatings and railway vehicles, which is applied in epoxy resin coatings, polyurea/polyurethane coatings, coatings, etc., can solve the problems of undisclosed self-temperature control of coatings, thick heating coatings, and thick electrothermal coatings, etc. Achieve the effect of eliminating the process of installation and running tests, reducing the difficulty of installation and reducing the thickness of the coating

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0069]

[0070]

[0071] Add the alkyl-modified carbon nanotubes, conductive carbon black and conductive titanium dioxide to the polyether polyurethane resin in proportion, then add the solvent propylene glycol methyl ether acetate and methyl isobutyl ketone and stir at a speed of 1500rpm for 0.5h Finally, ultrasonicate at 20°C and 40kHz for 20min, then continue to add various additives while stirring at a speed of 1000rpm (add in order of defoamer, dispersant, rheological agent, and drier), and finally add curing The dose is ready.

[0072]Spray the paint on the deicing and anti-icing parts of the locomotives. After it dries, spread copper paste electrodes on the surface according to the needs and existing conditions. The control module turns on or off the heating module, which can be used to prevent and remove icing of the rolling stock.

Embodiment 2

[0074]

[0075]

[0076] Add brominated n-hexadecane modified carbon nanotubes, graphite, graphene, conductive zinc powder and silver powder to bisphenol A epoxy resin E44 in proportion, and then add solvent methyl isobutyl ketone and butyl acetate After stirring with chloroform at a speed of 1000rpm for 1h, ultrasonic at 30°C and 60kHz for 40min, then continue to add various additives while stirring at a speed of 800rpm (according to defoamer, dispersant, rheological agent, catalyst, etc.) Add the dry agent sequentially), and finally add the curing agent.

[0077] Brush the paint on the deicing and anti-icing parts of the locomotives. After it dries, spread silver paste electrodes on the surface according to the needs and existing conditions. The heating module is turned on or off by using the control module, which can be used to prevent and remove the icing of the rolling stock.

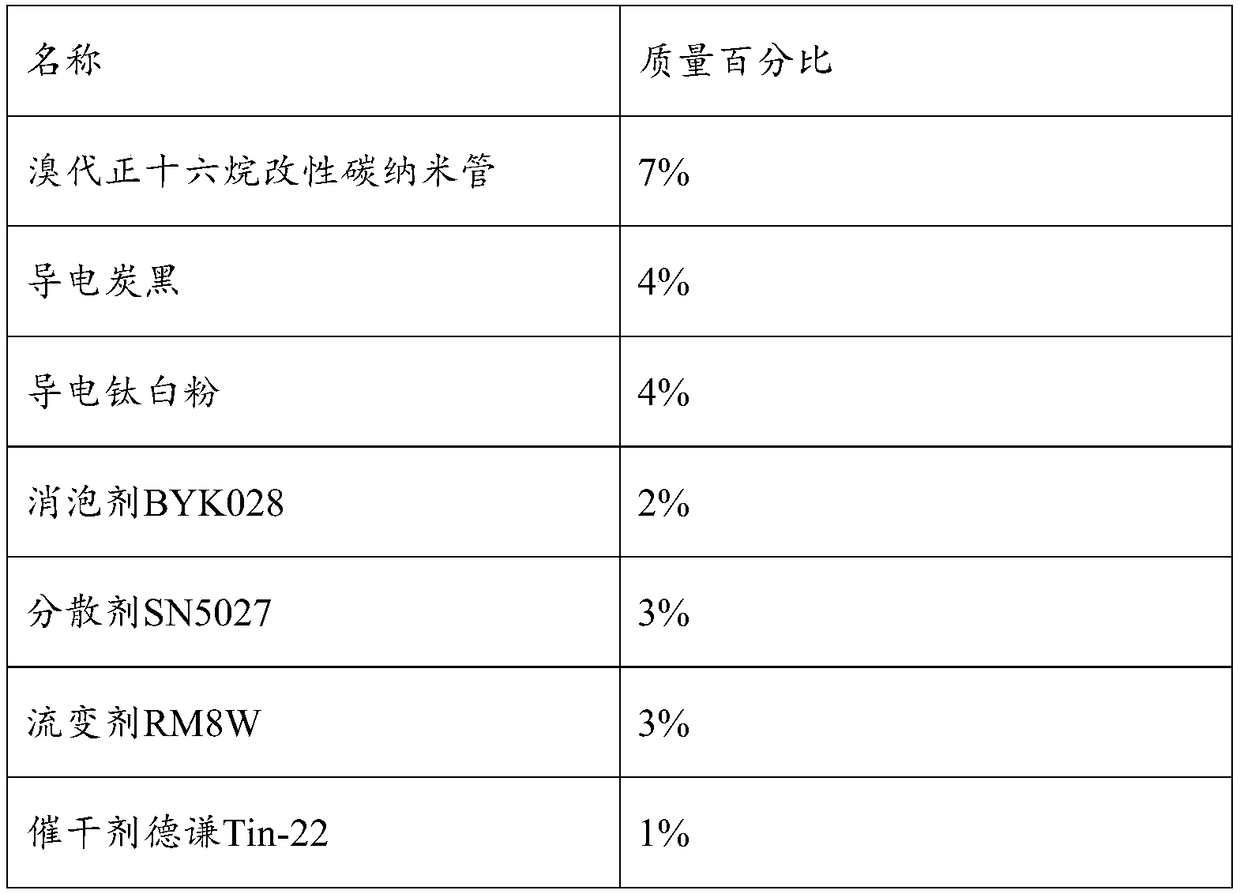

Embodiment 3

[0079]

[0080]

[0081] Add bromo-n-hexadecane modified carbon nanotubes, graphene, and silver-coated graphite powder into hydroxyacrylic resin in proportion, then add solvent toluene and methyl ethyl ketone at a speed of 1000rpm and stir for 1h. Ultrasound for 30 minutes, then continue to add various additives while stirring at a speed of 1000rpm (add in the order of defoamer, dispersant, rheological agent, and drier), and finally add curing agent.

[0082] Roll-coat the paint on the deicing and anti-icing parts of the locomotive and wait for it to dry. Spread copper wire electrodes on the surface according to the needs and existing conditions. After the power is turned on, use the ability of the coating film to conduct current to convert electrical energy into heat energy. The heating module is turned on or off by using the control module, which can be used to prevent and remove the icing of the rolling stock.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com