Series elutriation deep concentration process for extremely difficult-to-separate magnetite

A magnetite and elutriation technology, which is applied in the field of mineral processing, can solve the problems that the refractory magnetite concentrate cannot reach the standard, and achieve the effect of improving the sorting environment and reducing the viscosity of the pulp

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

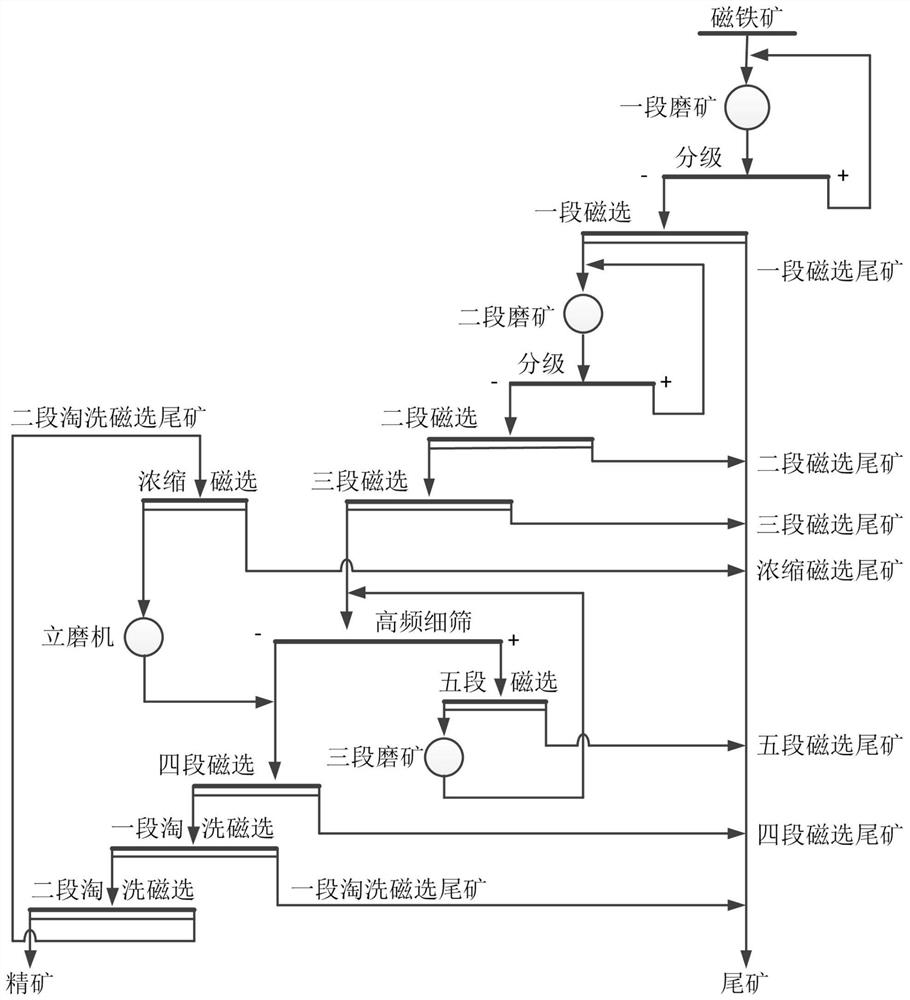

[0038] The above ore is sorted by adopting the technique of the present invention, and the technological process is as follows figure 1 As shown, the steps are:

[0039] 1) Feed the raw ore crushed below 16mm into the first stage of mill, and carry out a stage of grinding and classification operations to obtain a stage of graded overflow pulp and sand settling. The sand is returned to the first-stage mill for closed-circuit grinding;

[0040] 2) One section of graded overflow is given to one section of magnetic separation, and the field strength of one section of magnetic separation is 2500Oe to obtain one section of magnetic separation concentrate and one section of magnetic separation tailings;

[0041] 3) Put the first-stage magnetic separation concentrate into the second-stage grinding, and carry out the second-stage grinding and classification operation to obtain the second-stage classification overflow pulp and sand settling. The fineness of the overflow pulp is -0.074 ...

Embodiment 2

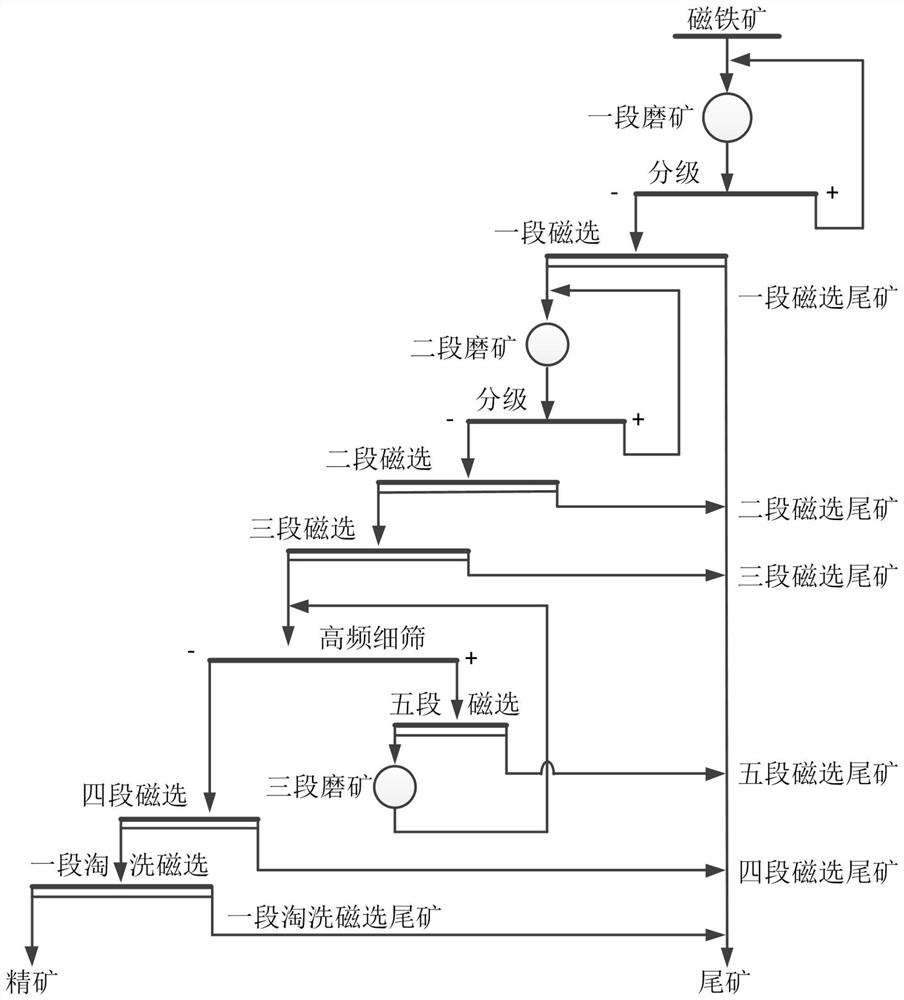

[0060] The current common "stage grinding-stage weak magnetic separation-concentrate elutriation magnetic separation process" is adopted for raw ore samples. The process flow is as follows figure 2 As shown, the steps are:

[0061] 1) Feed the raw ore crushed below 16mm into the first stage of mill, and carry out a stage of grinding and classification operations to obtain a stage of graded overflow pulp and sand settling. The sand is returned to the first-stage mill for closed-circuit grinding;

[0062] 2) One section of graded overflow is given to one section of magnetic separation, and the field strength of one section of magnetic separation is 2500Oe to obtain one section of magnetic separation concentrate and one section of magnetic separation tailings;

[0063] 3) Put the first-stage magnetic separation concentrate into the second-stage grinding, and carry out the second-stage grinding and classification operation to obtain the second-stage classification overflow pulp ...

Embodiment 3

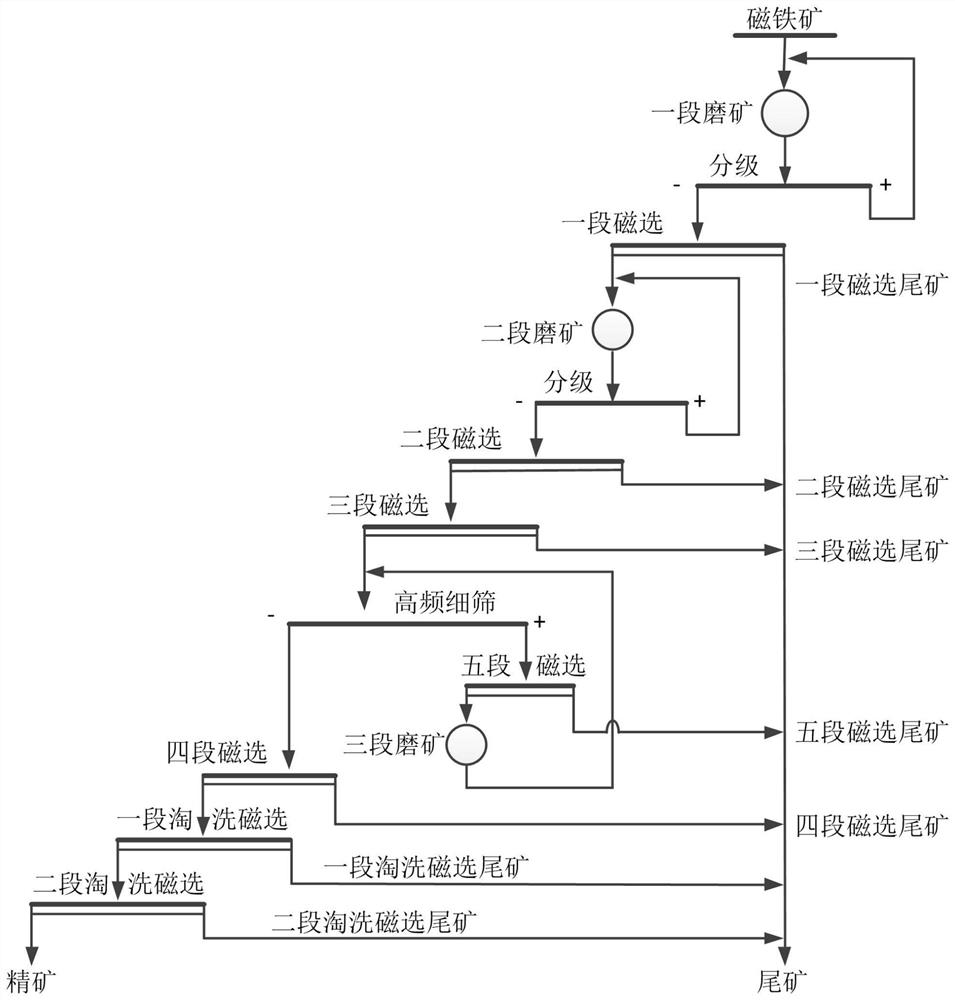

[0079] The raw ore samples are sorted by "open circuit series elutriation process". The process flow is as follows: image 3 As shown, the steps are:

[0080] 1) Feed the raw ore crushed below 16mm into the first stage of mill, and carry out a stage of grinding and classification operations to obtain a stage of graded overflow pulp and sand settling. The sand is returned to the first-stage mill for closed-circuit grinding;

[0081] 2) One section of graded overflow is given to one section of magnetic separation, and the field strength of one section of magnetic separation is 2500Oe to obtain one section of magnetic separation concentrate and one section of magnetic separation tailings;

[0082] 3) Put the first-stage magnetic separation concentrate into the second-stage grinding, and carry out the second-stage grinding and classification operation to obtain the second-stage classification overflow pulp and sand settling. The fineness of the overflow pulp is -0.074 and the par...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Fineness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com