Multi-dimensional swinging sand stone sieving device based on swinging feeding

A multi-dimensional, sand and gravel technology, applied in the field of engineering construction and sand and gravel screening, can solve the problems of low contact sufficiency, insufficient screening efficiency, and limited screen movement dimensions.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

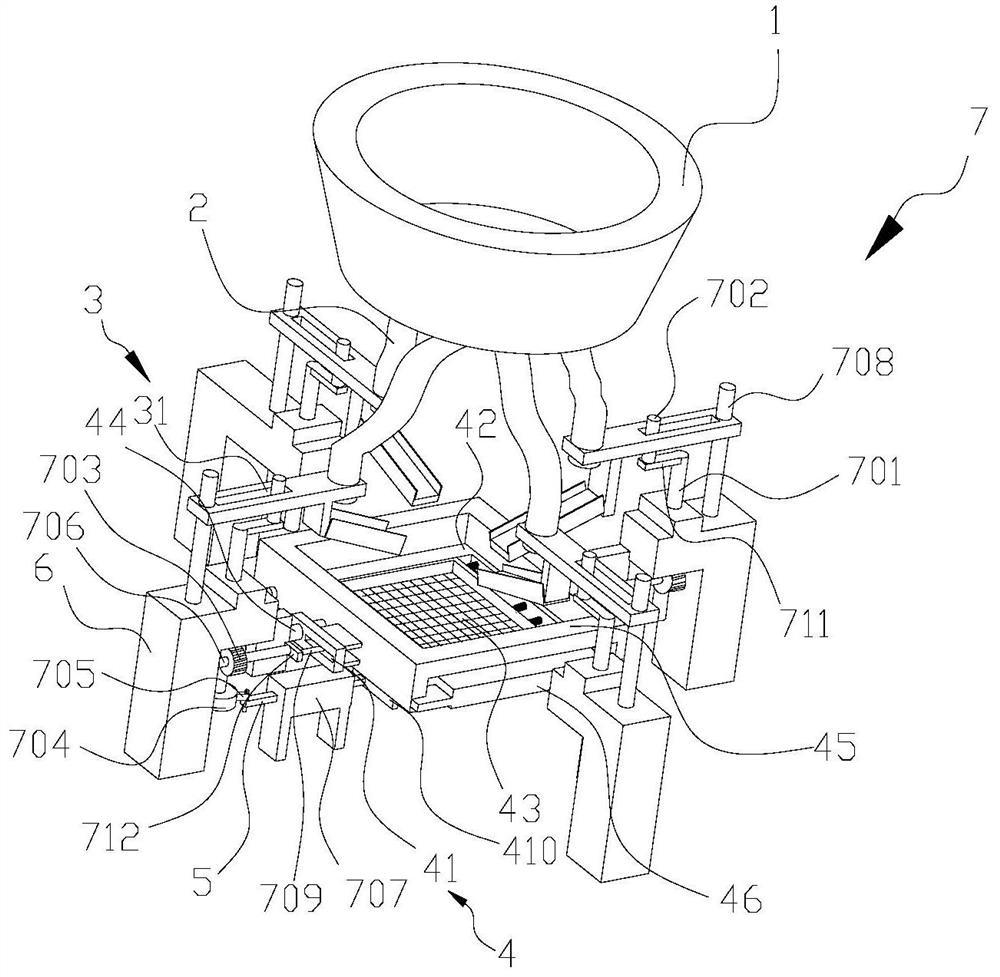

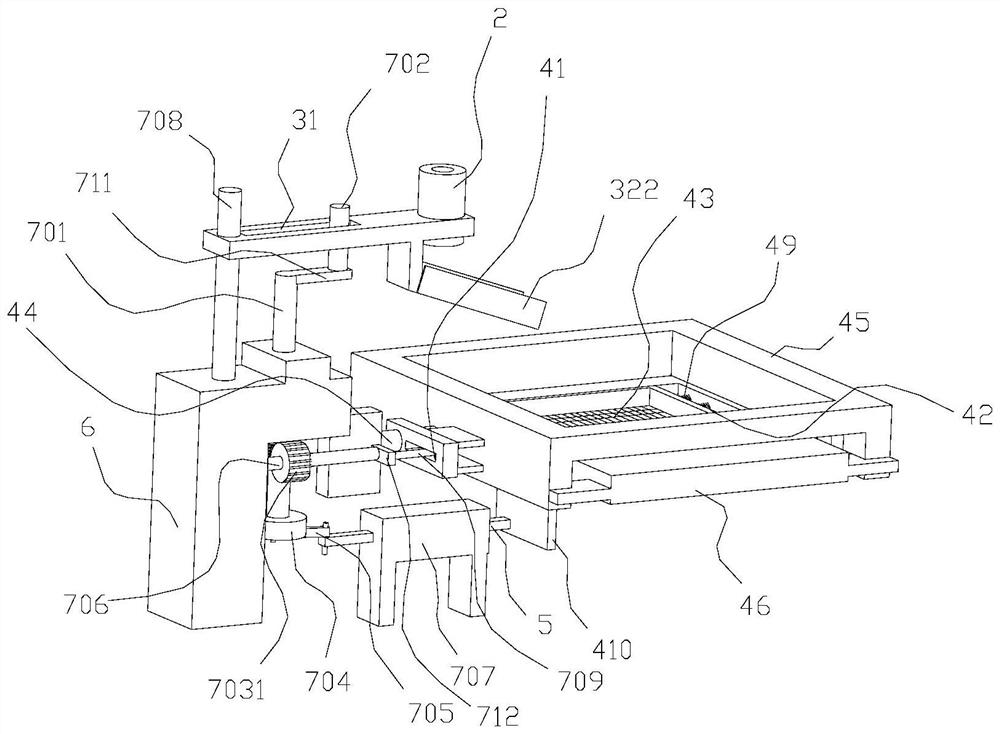

[0060] Such as figure 1 As shown, this embodiment discloses a multi-dimensional rocking sand screening device based on swing feeding, including a feeding bin 1, a feeding pipe 2, a swing feeding rack 3, a screening device 4, a reciprocating translation rod 5, Frame 6, linkage device 7.

[0061] The feeding bin 1 is located above the screening device 4 , the feeding end of the feeding pipe 2 communicates with the feeding bin 1 , and the discharging end of the feeding pipe 2 is arranged on the swing loading rack 3 . The swing of the swing loading rack 3 drives the feed pipe 2 to swing, and the sand flowing out from the discharge end of the feed pipe 2 can fall onto the screen 43 of the sieving device 4 .

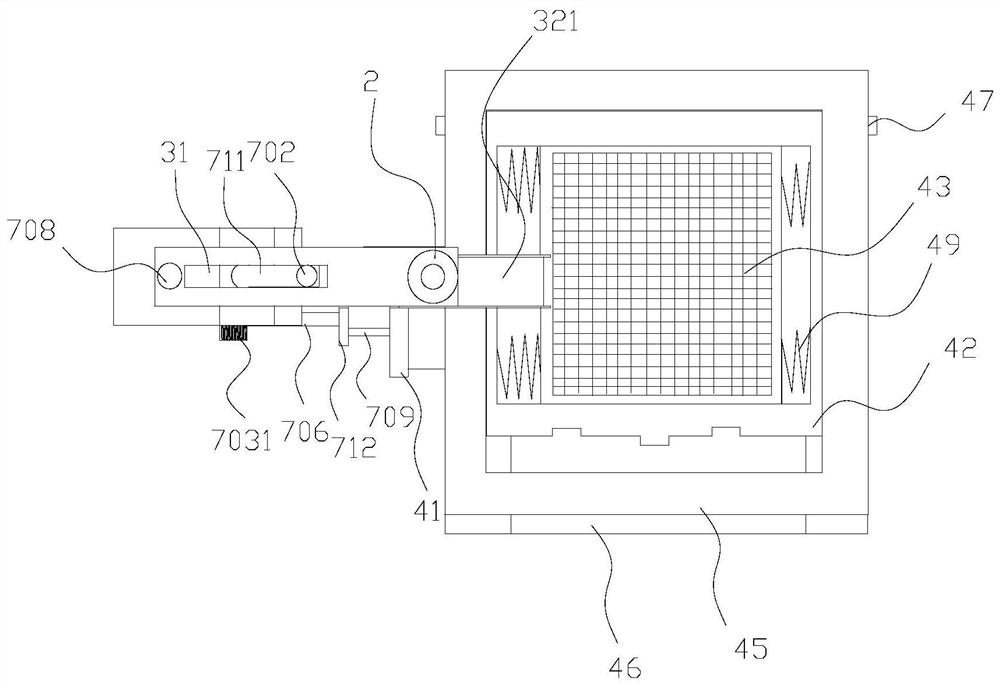

[0062] Such as Figure 2-4 As shown, the sieving device 4 rotates and cooperates with the frame 6 through a rotating shaft. The sieving device 4 includes a sieving frame 42 and a sieve 43 , and the sieve 43 is built in the sieving frame 42 . A push plate 410 is also connect...

Embodiment 2

[0071] Such as Figure 5-7 As shown, the difference between this embodiment and the above-mentioned embodiments is that a plurality of swinging feeding frames 3 surround the periphery of the screening device 4 . Each rotating shaft 701 is sleeved with a pulley 713 , and all the pulleys 713 are linked by a belt 714 .

[0072] The present invention further satisfies the uniformity of large-scale and large-scale dispersion of sand and gravel in the large-scale screening device by arranging multiple swinging feeding racks 3 and surrounding the multiple swinging feeding racks 3 on the periphery of the screening device 4; And by being all sleeved with pulley 713 on each rotating shaft 701, all pulleys 713 are sleeved on the belt 714, have realized that all swing feeding racks 3 work synchronously, during construction, on one of rotating shaft 701 Just configure the motor on it. Belt pulley 713 of the present invention also can adopt gear to replace, and belt 714 adopts chain to re...

Embodiment 3

[0076] When there are many stones and large grains of sand accumulated in the screen cloth 43, they need to be unloaded in time, otherwise the normal screening of the screen cloth 43 will be affected.

[0077] Such as Figure 8 , 9 As shown, in order to realize the timely and efficient discharge of the stones and large grains of sand accumulated in the screen 43 , the screening device 4 of this embodiment also includes a peripheral frame 45 and a locking member 46 .

[0078] The peripheral frame 45 is hollowed out up and down, closed on three sides, and opened on one side. One end of the sieve frame 42 is pivotally connected with the peripheral frame 45, the other end of the sieve frame 42 is a free end and can extend toward the open end of the peripheral frame 45, and the locking member 46 is slidably fitted with the open end of the peripheral frame 45 to Sliding the lock piece 46 inside (towards the free end direction of the screen frame 42) can cause the end of the lock p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com