A clamping device for machining

A mechanical processing and splint technology, applied in metal processing and other directions, can solve the problems of easy falling off and inconvenient clamping of heavy objects, and achieve the effect of strengthening the clamping effect and facilitating mechanical processing.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

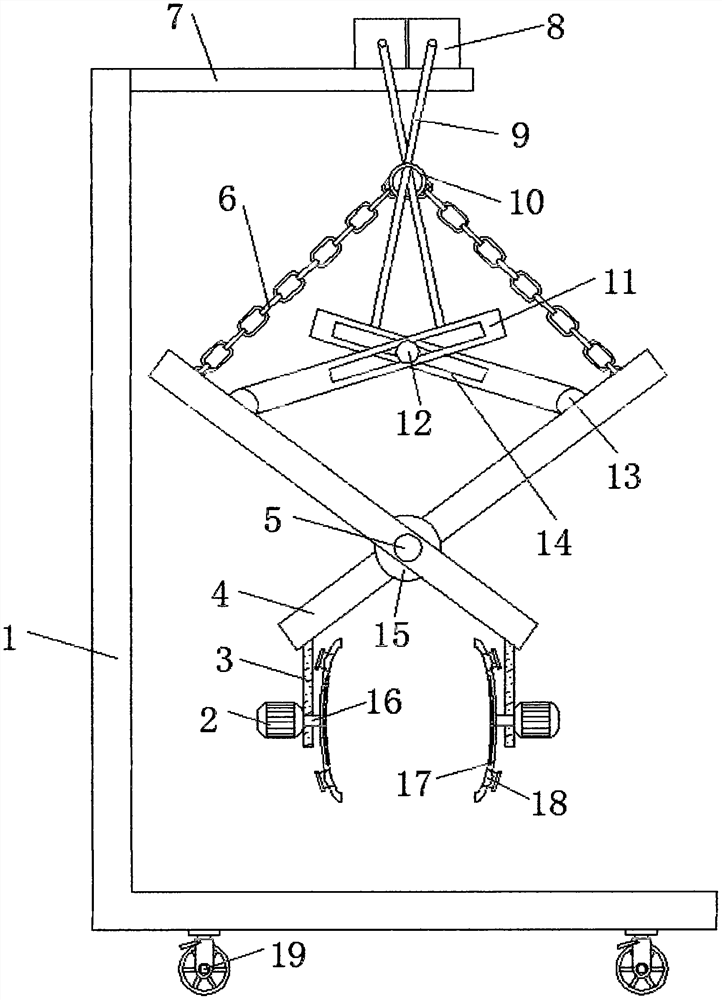

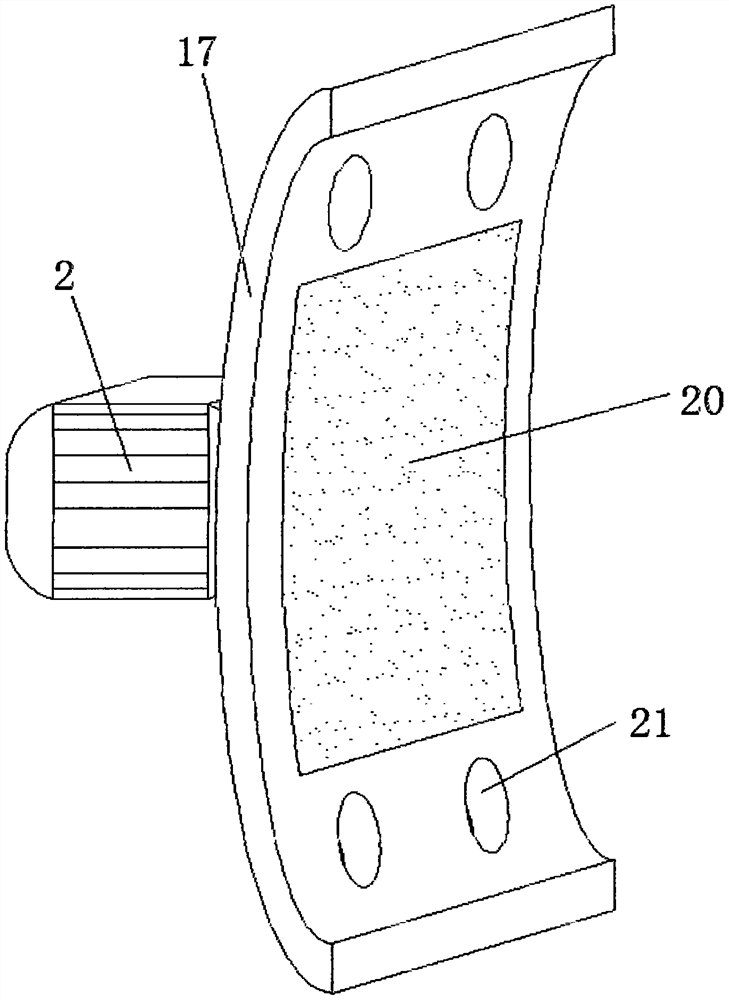

[0025] refer to Figure 1-2 , a clamping device for mechanical processing, including an L-shaped plate 1 and two steering handles 4, a top plate 7 is fixed by bolts on one side of the outer wall of the L-shaped plate 1 near the top, and the top outer wall of the top plate 7 is fixed by bolts There are two servo motors 8, and the same round rod 5 is inserted and rotated on one side of the outer wall of the two steering handles 4, and the outer wall of one side of the round rod 5 is fixed with a fixing seat 15 by bolts, and the two steering handles 4 are opposite to each other. A clamping mechanism is provided on one side of the outer wall near the bottom, and a hinge seat 13 is installed on the opposite side of the two steering handles 4 near the top, and the outer walls of the two hinge seats 13 are hinged with connecting rods 11. A rope 9 is wound around one end of the output shafts of the two servo motors 8 , and one end of the rope 9 is respectively bolted to one side outer...

Embodiment 2

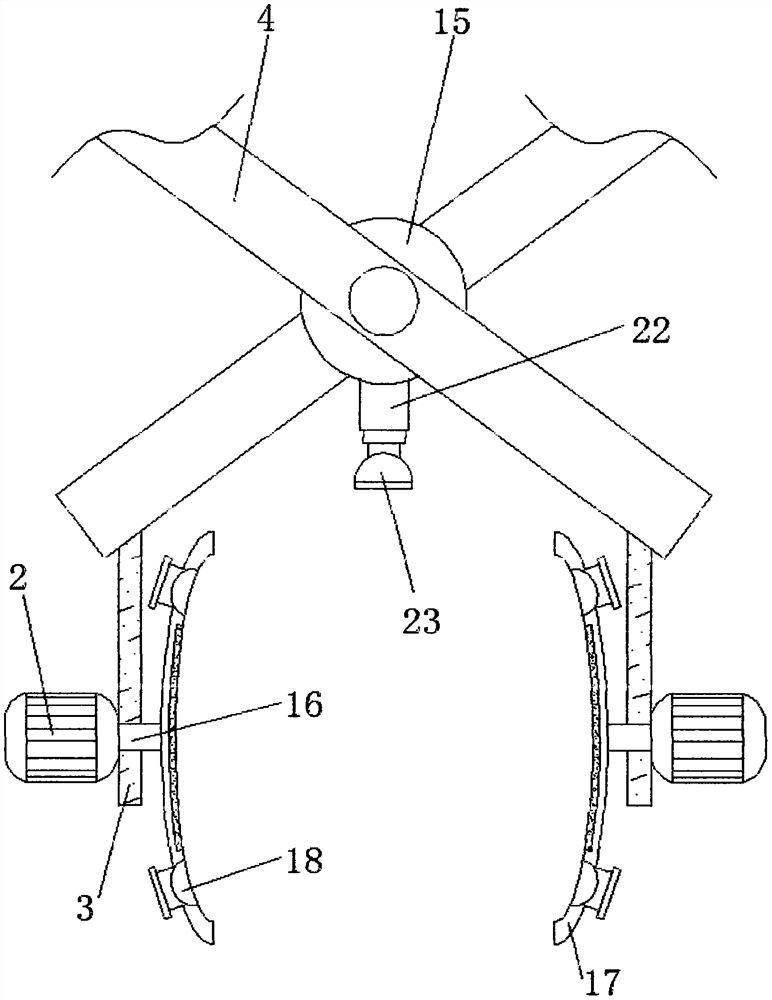

[0030] refer to image 3 , a clamping device for mechanical processing. Compared with Embodiment 1, the outer wall of the bottom of the fixed seat 15 is fixed with an electric telescopic rod 22 through a bolt, and one end of the extension rod of the electric telescopic rod 22 is fixed with a second bolt. Two electromagnetic chucks 23.

[0031] During use, the second electromagnetic chuck 23 can be used for auxiliary adsorption on the top of the clamping part when clamping, and the electric telescopic rod 22 is used to move the second electromagnetic chuck 23 to the surface of the clamping part, and then start the second electromagnetic chuck 23 carries out adsorption, and the fixing of auxiliary clip.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com