A kind of wormwood modified veneer and preparation method thereof

A veneer and wormwood technology, applied in veneer presses, manufacturing tools, plywood presses, etc., can solve the problems of restricting the use of veneer panels, reducing the impact resistance of veneer panels, etc., and achieve strong self-extinguishing ability and excellent antibacterial Anti-mildew and anti-insect performance, high surface waterproof effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

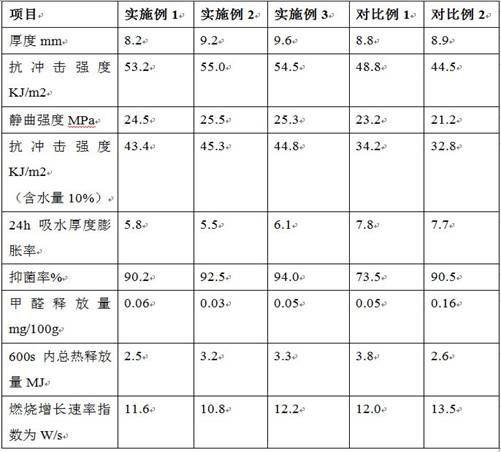

Examples

Embodiment 1

[0042] Embodiment 1 A kind of wormwood modified veneer and preparation method thereof

[0043] 1. Material selection

[0044] Select high-quality wood, process the wood into planks with a thickness of 8mm, then put the planks into a microwave dryer for drying, reduce the moisture content of the planks to 4.5%, and obtain the base material for use;

[0045] The wood is eucalyptus;

[0046] 2. Preparation of modified melamine formaldehyde resin

[0047] 1) Dissolve formaldehyde in ethanol solution, add urotropine, then add dropwise 40% NaOH solution to adjust the pH to 8.0, stir and mix well;

[0048] 2) Add melamine while stirring, heat up to 70°C, keep warm and react, and the solution is clear and transparent;

[0049] 3) Add modifier ethylenediamine tetramethylene phosphonic acid to the system, increase the stirring rate, continue to stir for 1 hour until the viscosity of the system increases, stop heating, and cool with room temperature to obtain a colorless, transparent ...

Embodiment 2

[0077] Embodiment 2 A kind of wormwood modified veneer and preparation method thereof

[0078] 1. Material selection

[0079] Select high-quality wood, process the wood into planks with a thickness of 8mm, then put the planks into a microwave dryer for drying, reduce the moisture content of the planks to 4.0%, and obtain the base material for use;

[0080] The wood is eucalyptus;

[0081] 2. Preparation of modified melamine formaldehyde resin

[0082] 1) Dissolve formaldehyde in ethanol solution, add urotropine, then add dropwise 40% NaOH solution to adjust the pH to 8.8, stir and mix well;

[0083] 2) Add melamine while stirring, heat up to 70°C, keep warm and react, and the solution is clear and transparent;

[0084] 3) Add modifier ethylenediaminetetramethylene phosphonic acid to the system, increase the stirring rate, and continue to stir for 1.5 hours until the viscosity of the system increases, stop heating, and cool with room temperature to obtain a colorless, transp...

Embodiment 3

[0112] Embodiment 3 A kind of wormwood modified veneer and preparation method thereof

[0113] 1. Material selection

[0114] Select high-quality wood, process the wood into planks with a thickness of 8mm, then put the planks into a microwave dryer for drying, reduce the moisture content of the planks to 3.5%, and obtain the base material for use;

[0115] The wood is eucalyptus;

[0116] 2. Preparation of modified melamine formaldehyde resin

[0117] 1) Dissolve formaldehyde in ethanol solution, add urotropine, then add dropwise 40% NaOH solution to adjust the pH to 8.9, stir and mix well;

[0118] 2) Add melamine while stirring, heat up to 70°C, keep warm and react, and the solution is clear and transparent;

[0119] 3) Add modifier ethylenediamine tetramethylene phosphonic acid to the system, increase the stirring rate, continue to stir for 1 hour until the viscosity of the system increases, stop heating, and cool with room temperature to obtain a colorless, transparent ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| impact strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com