Loading station chute for mixed unit train and loading method

A loading station and chute technology, which is applied in the field of loading station chute and vehicle loading for mixed trains, can solve the problems of less serious problems, poor precision, large volume, etc., and achieve the effect of improving the uniformity of loading

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

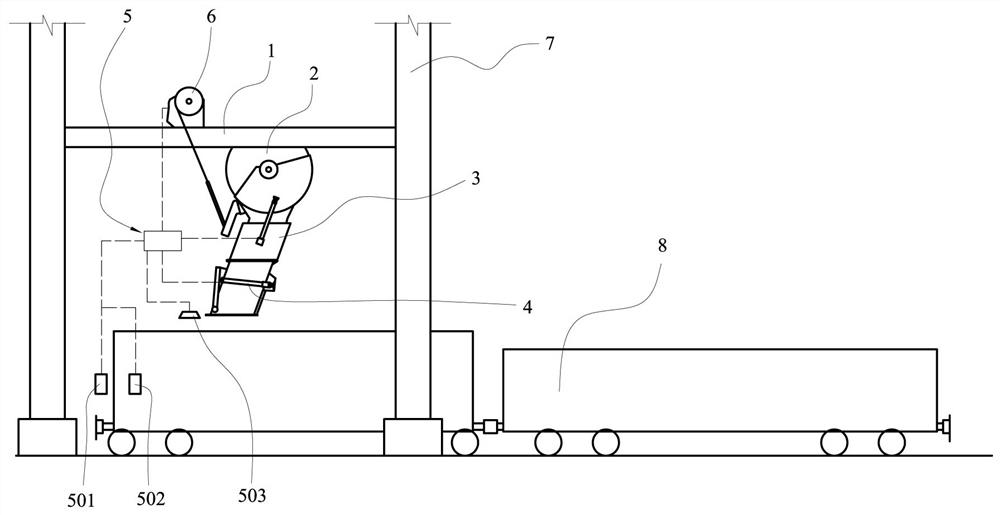

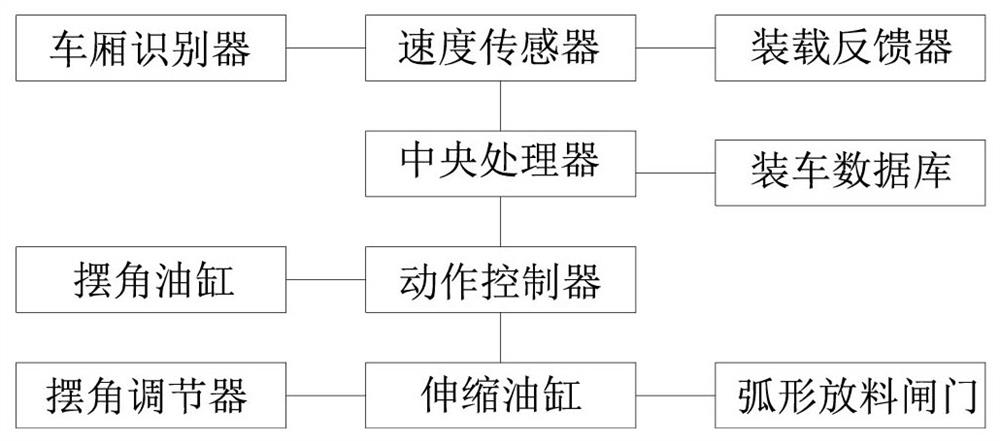

[0034] This embodiment is a loading station chute for mixed trains, such as figure 1 , 2 , 3 shown. This embodiment is applied to the automatic fast loading of bulk materials with high density, realizes the loading of mixed compartments 8 of different heights, and effectively avoids the problem of unbalanced load. The chute described in this embodiment includes: a chute fixing frame 1 , a fixed arc pod 2 , a swinging distribution pipe 3 , a swing angle regulator 6 , and an intelligent control device 5 . The chute fixed frame is fixedly connected on the steel structure frame 7 of loading station. The loading station described in this embodiment is an automatic loading device specially used for loading bulk goods for train carriages. There are various forms of loading stations. The main structure of the conventional loading station is the steel frame as the main body, and the belt machine head, buffer warehouse, quantitative warehouse and chute are arranged in sequence from t...

Embodiment 2

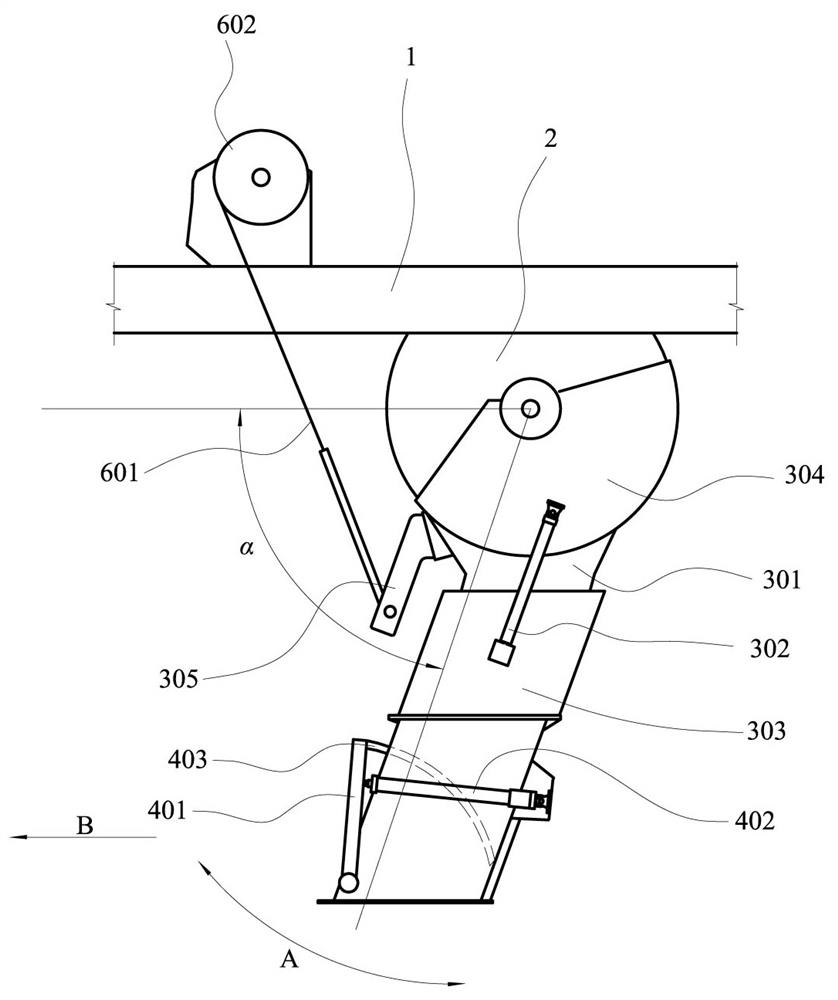

[0045] This embodiment is an improvement of the above-mentioned embodiment, and it is a refinement of the above-mentioned embodiment on the swinging distribution pipe. The swing angle adjuster described in this embodiment controls the swing angle between the swinging distribution pipe and the horizontal plane α Swing within 15° to 75°, such as image 3 shown.

[0046] The swinging cloth pipe is provided with a connection seat 305, which connects the traction wire rope 601 of the swing angle adjuster, and the swing angle adjuster is arranged on the chute fixed mount. The swing angle regulator controls the tilt angle between the swing cloth pipe and the horizontal plane to swing between 15° and 75°. image 3 The arrow A in the figure indicates the direction of the train movement, and the arrow B indicates the swing direction of the swinging distribution pipe. The counterclockwise rotation is negative, and the clockwise rotation is positive.

[0047] Implementation three:

[0...

Embodiment 4

[0051] This embodiment is an improvement of the above-mentioned embodiment, and it is a refinement of the telescopic section of the swinging cloth pipe in the above-mentioned embodiment. A plurality of rolling bodies are uniformly arranged between the inner sleeve and the four walls of the outer sleeve of the telescopic section described in this embodiment as needle rollers. rolling guide 306, such as Figure 4 shown.

[0052] The slideway between the inner and outer jackets of this embodiment is different from the guide rail of the conventional chute. It adopts a high-precision, impact-resistant needle roller as a rolling guide rail, and realizes the stable expansion and contraction of the inner and outer chute under the control of the telescopic oil cylinder. Deformation, no deviation.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com