Making method of rose Maotai-flavor liquor

A production method, the technology of rose sauce, applied in the field of wine making, can solve the problems of large floating fragrance, small aftertaste, unstable shelf life, etc., and achieve the effect of full and soft fragrance and realization of upgrading

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

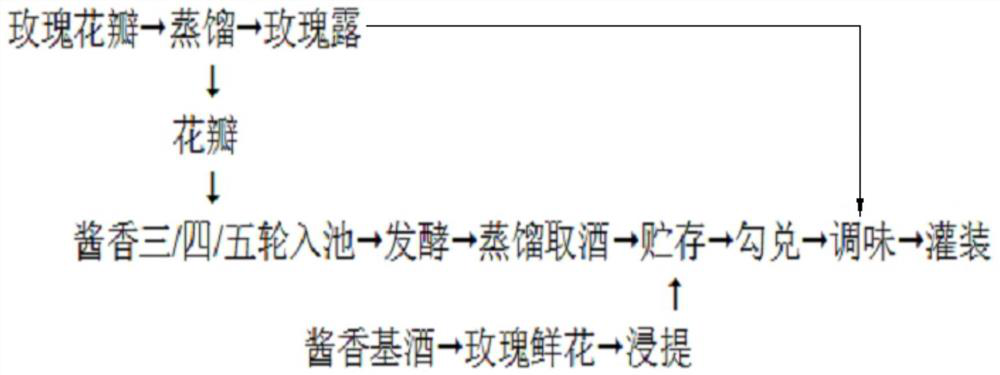

Method used

Image

Examples

Embodiment 1

[0036] S1. Distillation of roses: heat the picked fresh roses in hot water at 60-65°C to extract rose water, collect low-boiling aroma components, and avoid losses during subsequent fermentation, distillation, and storage. Has a very good pre-fragrance effect;

[0037] S2. Fermentation with rose petals: from the third round of brewing of the Maotai-flavored wine, add koji when the fermented grains drop to 28-30°C, and add rose petals that account for 2-3% of the weight of the feed at the same time after distilling rose water. After mixing evenly, continue to pile up and ferment into the tank according to the normal operation; because the petals contain rich floral components, after fermentation, some components become the precursor substances of fermentation aroma to generate new aromas, and some components are directly dissolved in wine, which is normal to white wine The aroma produced by fermentation complements and complements each other to make the aroma more plentiful. Wh...

Embodiment 2

[0045] S1. Soak the rose petals after distilling rose dew with 53% vol sauce-flavored liquor for 15-20 days, take the extracted wine and reduce the concentration to 10-20% vol as aroma-enhancing wine for later use;

[0046] S2. From the third round of brewing of Maotai-flavored liquor, add koji when the fermented grains drop to 28-30°C, and add the rose petals extracted from the wine at the same time, and continue to pile up in the same way as Maotai-flavored liquor. Sprinkle aroma-enhancing wine evenly in the medium for fermentation, and bring the rich floral ingredients contained in the petals into the cellar;

[0047] S3. The operations of the fourth and fifth rounds are the same as those of the third round;

[0048]S4. Distilling wine: mix the fermented grains out of the pond into the steamed rice husk, see steaming steamer, slowly distill, and control the time of steamer filling at 36-40min, avoiding the rapid filling of steamer on high fire, causing the temperature to be...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com