Energy dissipation connecting piece for bamboo-wood shear wall

A technology of connectors and shear walls, applied in the direction of walls, building components, building structures, etc., can solve the problems that the performance of bamboo and wood materials cannot be fully exerted, the structural safety factor is reduced, and the bolts and nails are deformed. Service life and applicability, the effect of improving shear resistance and improving seismic performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

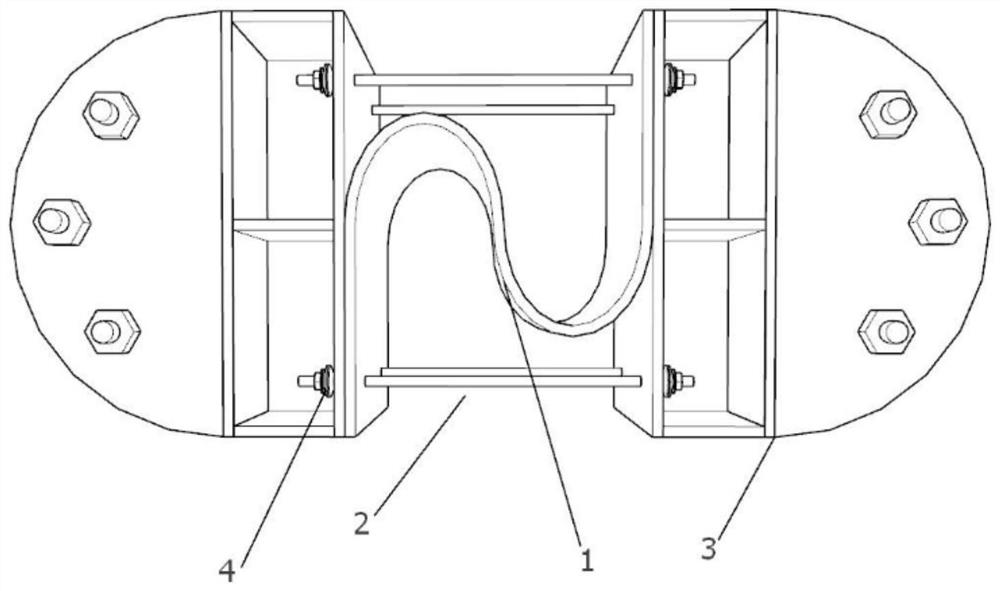

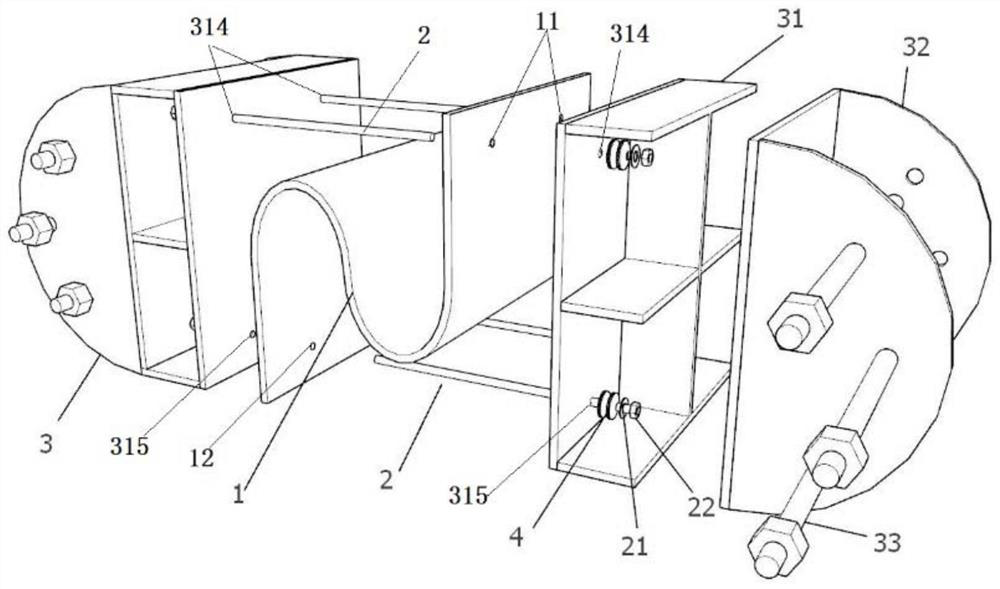

[0026] According to the attached Figure 1-5 The specific embodiment of the present invention is further described:

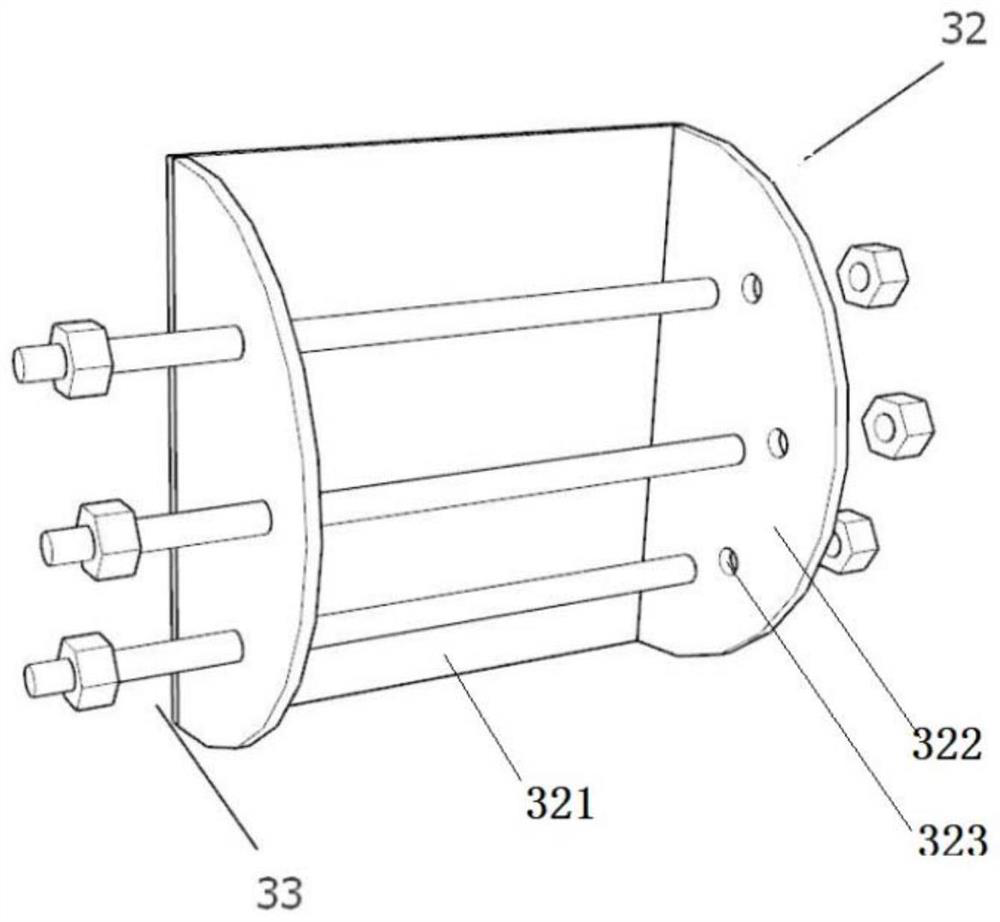

[0027] A kind of bamboo-wood shear wall energy-dissipating connector, such as figure 2 As shown, it includes N-type energy dissipation plate 1, energy dissipation shape memory alloy rod 2, butterfly spring 4, steel washer 21, nut 22, fan-shaped connecting piece 3 and high-strength bolt 33, and the fan-shaped connecting piece 3 includes a cross bottom plate 31 and fan-shaped connecting plate 32, such as Figure 4 As shown, the cross base plate 31 includes a base plate base 311, a base plate baffle plate 312 and a cross partition 313, the base plate baffle plate 312 has two pieces and is vertically fixed on the upper and lower ends of the base plate base 311, and the cross partition plate 313 is vertical Fixed on the inside of the base plate base 311, the upper end of the base plate base 311 is provided with a through hole 1 314, and the lower end of the base ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com