Vertical sliding device for displacement one-way control

A one-way control, sliding device technology, applied in the processing of building materials, construction, building structure, etc., can solve the problem that the outrigger truss cannot be fixed in time, so as to improve the construction efficiency, ensure the construction quality, and eliminate the impact. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

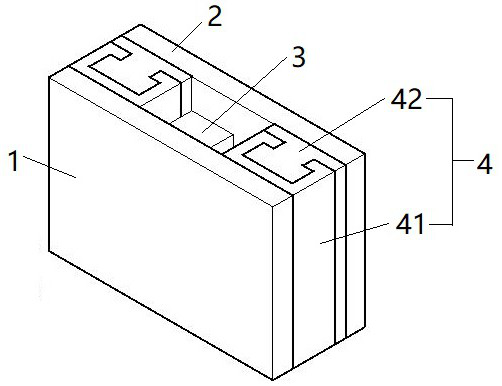

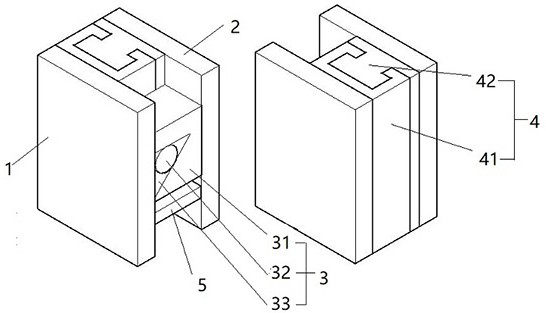

[0037] refer to figure 1 , Figure 5 , the technical solution of a vertical sliding device for one-way control of displacement in this embodiment is as follows:

[0038] A vertical sliding device for one-way control of displacement, comprising a truss left connecting plate 1, a truss right connecting plate 2, a sliding limit device 3, and a sliding track 4, the truss left connecting plate 1, and the truss right connecting plate The plates 2 are movably connected through the sliding track 4, and relatively slide in the vertical direction; the sliding limit device 3 is arranged between the left connecting plate 1 of the truss and the right connecting plate 2 of the truss, and the right connecting plate 2 of the truss is limited by sliding. The positioning device 3 slides in one direction relative to the left connecting plate 1 of the truss.

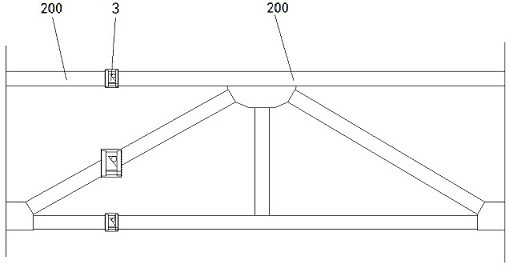

[0039] A vertical sliding device for one-way control of displacement in this embodiment is used to connect two sections of outrigger tru...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com