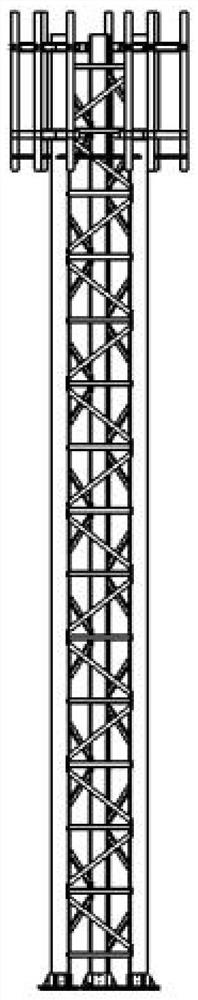

Lattice composite-material tower

A composite material and lattice technology, applied in towers, building types, buildings, etc., can solve the problems of easy cracks in welded joints, product self-heavy, high maintenance costs, and achieve simple on-site installation, strong connection reliability, and high reliability. The effect of easy molding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The technical solutions in the embodiments of the present invention will be clearly and completely described below in conjunction with the drawings in the embodiments of the present invention.

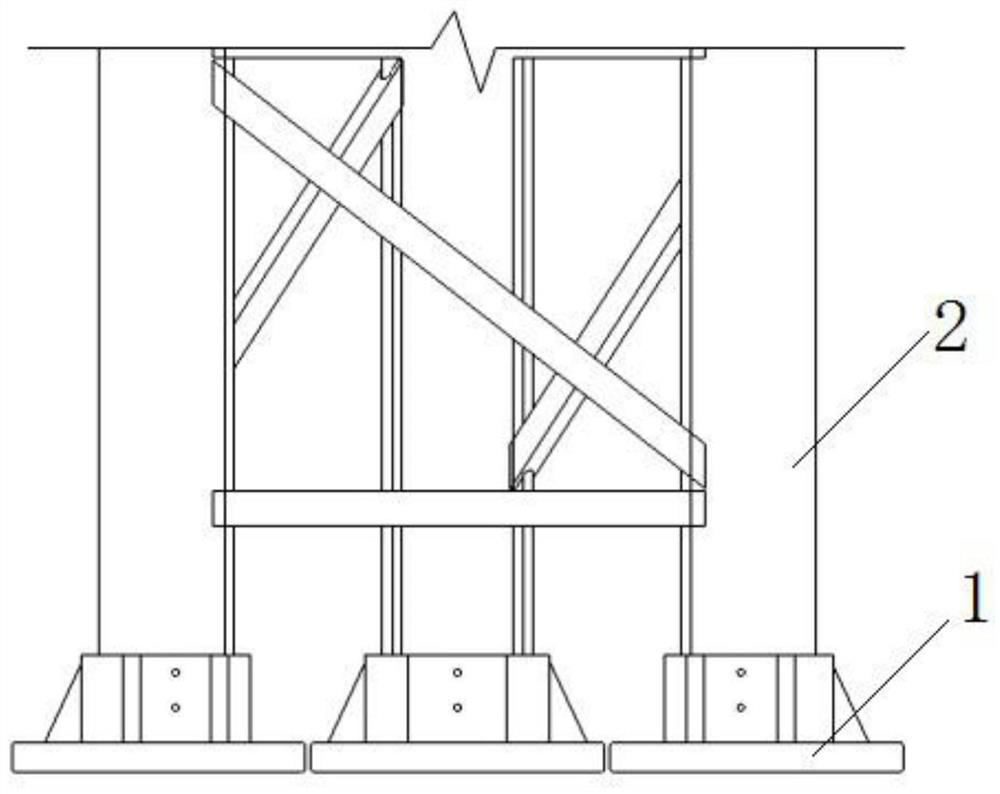

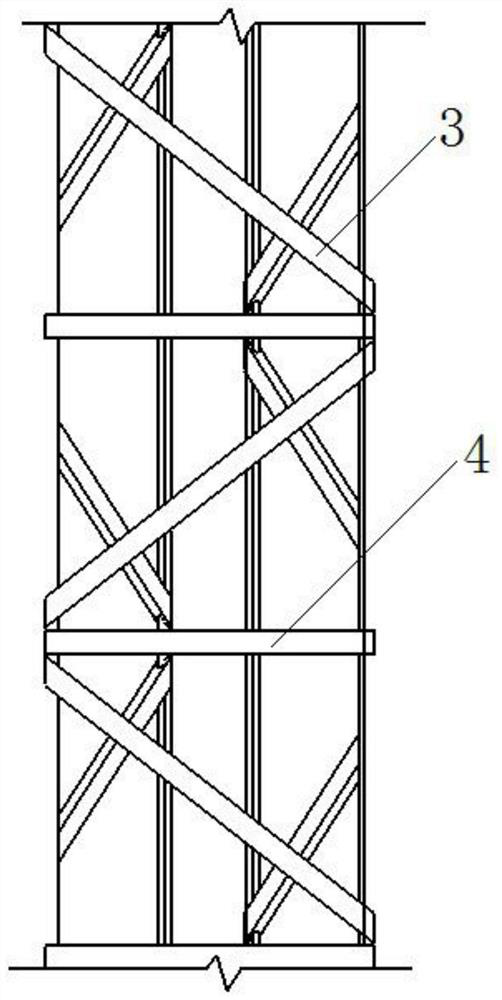

[0025] see Figure 1-8 Describe this embodiment, a lattice type composite material tower, which includes a base 1, a main girder 2, a diagonal tie rod 3, a transverse tie rod 4, an adapter 5, a channel profile 6 and a holding rod 7, the base 1. There are multiple bases 1 distributed in the form of corner points and fixedly connected to the ground. Each base 1 is fixedly connected with a main beam 2, and adjacent main beams 2 are connected with A plurality of diagonal tie rods 3 and cross tie rods 4, the cross tie rods 4 are arranged between adjacent diagonal stay rods 3, the top of the main beam 2 is fixedly connected with the channel profile 6 through the adapter 5, and the channel profile 6 is fixedly connected with a plurality of holding poles 7, and the pole towers are made...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com