Magnetic drive type mechanical coded lock

A mechanical combination lock and magnetic drive technology, applied in the field of magnetic drive mechanical combination locks, can solve the problems such as the confusion of the numbers of the dial front sight, the complicated operation process of the sign, the trouble for the user, etc., to achieve a simplified structure, easy memory, and convenient locks. Assembly effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

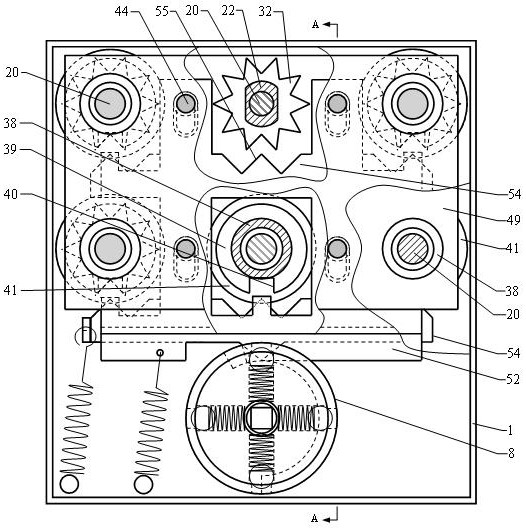

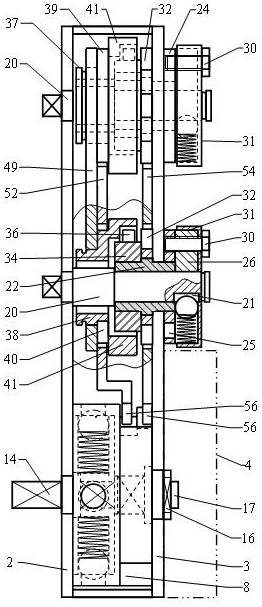

[0069] Such as figure 1 , 2 , 3, the magnetically driven mechanical combination lock includes a lock body 1, a buckle cover 4, a lock outer panel 5 and a handle, and the lock outer panel 5 is equipped with a handle and 6 mutually independent knob plates 6 and corresponding 6 A knob shaft 7. The lock body 1 is in the shape of a rectangle, the side panel located on the outside is the outer side panel 2 of the lock body, the side panel located on the inside is the inner side panel 3 of the lock body, and the inner lower part of the inner side panel 3 of the lock body is assembled with the buckle cover 4, The cavity formed by the two and the outside of the buckle cover 4 are used to assemble the unlocking actuator, and the unlocking and locking are completed by driving the lock bolt and the dead bolt. The lower side of the lock body 1 is provided with a cam mechanism.

[0070] Such as Figures 25 to 32 As shown, the cam mechanism includes a cam 8, a round table 13, a round tab...

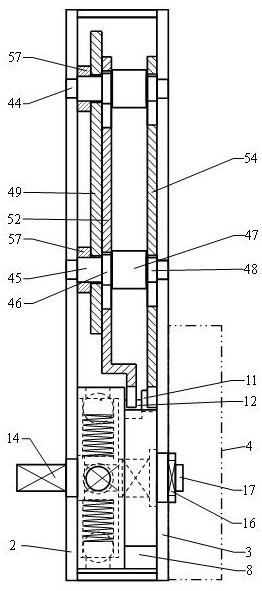

Embodiment approach 2

[0090] Such as Figure 35 , 36 , 38, the plate 52 of the lockset of the present invention can also be replaced by a flat plate without bending. Such as Figure 37 As shown, the plate shaft 46 of the corresponding guide shaft 44 moves between the limit shaft 47 and the lock plate shaft 48 and has the same diameter as the lock plate shaft 48 . A backing ring 57 is movably assembled between the no-bend insert plate and the locking plate. Such as Figure 39 , 40 , Shown in 41, the step in the middle part of the follower wheel 37 is the notch wheel and has been canceled, and the follower notch 40 is arranged on the outer circular surface of the annular wheel 41 of the follower wheel 37, and the lock performance remains unchanged.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com