Electric variable frequency rotary type air compressor for new energy vehicle

A technology for air-conditioning compressors and new energy vehicles, applied in the field of compressors, which can solve problems such as high manufacturing costs, complicated finishing and welding equipment, and large investment, so as to improve reliability and service life, save oil and gas separators, and reduce manufacturing costs Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

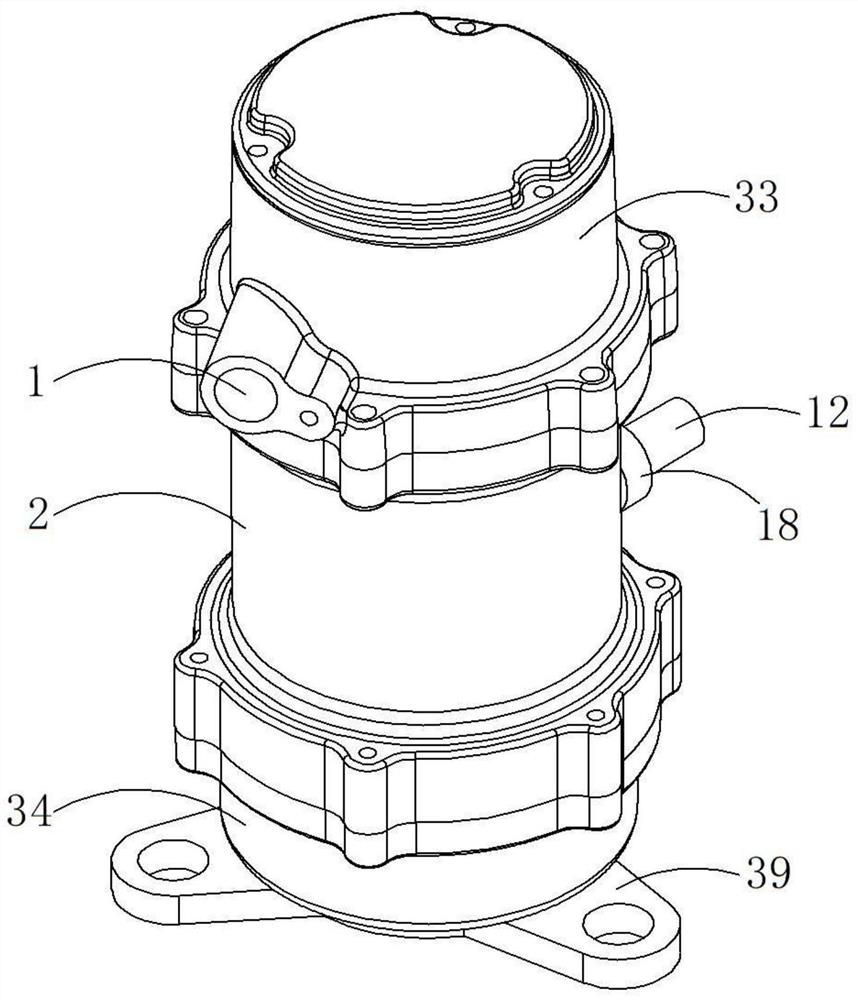

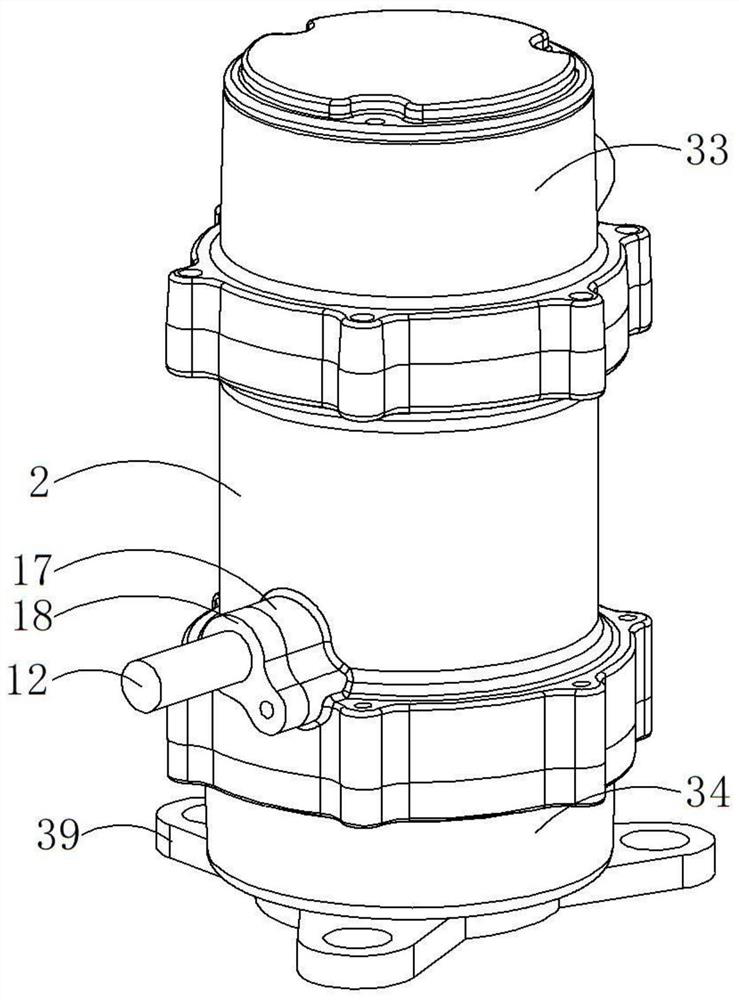

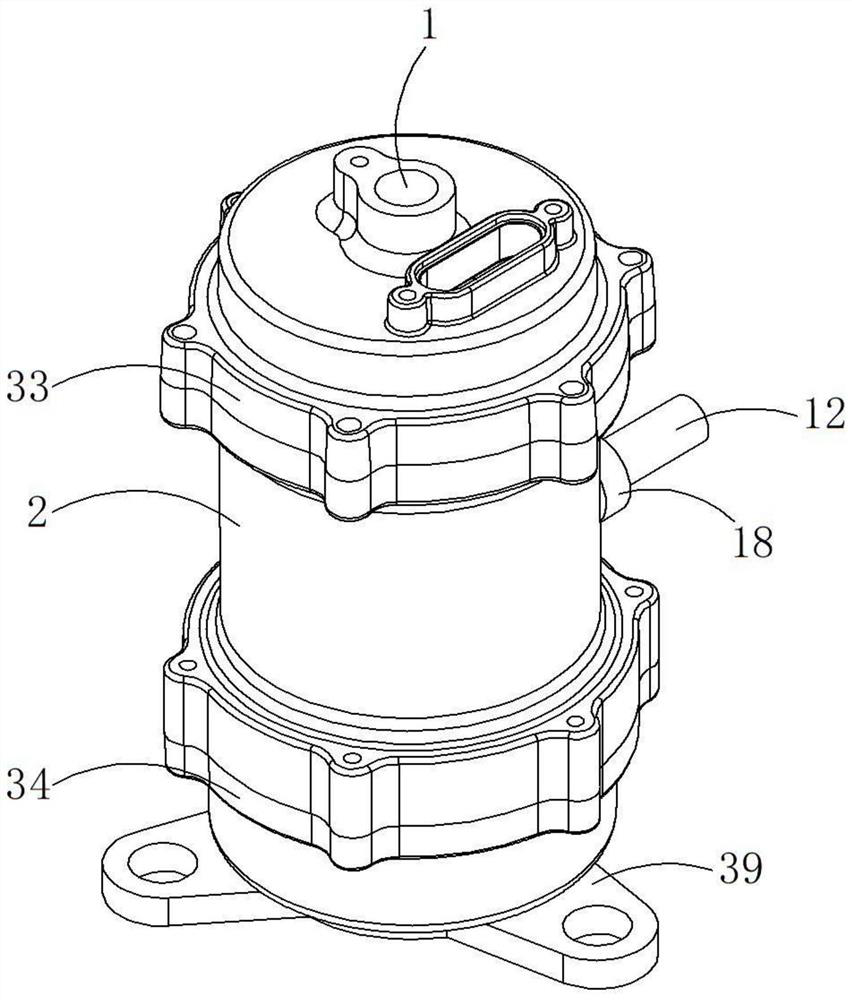

[0049] The frequency conversion electric rotary air conditioner compressor for new energy vehicles includes a housing 2 made of aluminum alloy, an upper end cover 33 made of aluminum alloy that is set on the upper end of the housing 2 and an upper end cover 33 that is located on the lower end of the housing 2. The lower end cover 34 made of aluminum alloy, the upper end cover 33 is fixed on the housing 2 by bolts, the lower end cover 34 is fixed on the housing 2 by bolts, and the seventh sealing ring 35 is arranged between the upper end cover 33 and the housing 2, An eighth sealing ring 36 is arranged between the lower end cover 34 and the housing 2 so that the inner cavity of the housing 2 forms an airtight airtight cavity.

[0050] like Figure 4 As shown, the upper end cover 33 is provided with a sealing cavity 40, the sealing cavity 40 is separated from the inner cavity of the housing 2 by a partition arranged in the upper end cover 33, and a terminal is provided in the se...

Embodiment 2

[0064] The structure of this embodiment is basically the same as the structure principle of Embodiment 1, the difference is that the compressor is a split compressor, and the controller is not set in the upper end cover 33 / housing 2 / lower end cover 34, that is, the controller located outside the compressor. Such as image 3 As shown, the first air inlet 1 is located on the top of the upper end cover 33 .

Embodiment 3

[0066] The structure of this embodiment is basically the same as the structure principle of Embodiment 1, the difference is that, as Figure 9 with Figure 10 As shown, the housing 2 is provided with a third outlet 30 communicating with the inner cavity of the housing 2 and a fourth inlet 31 coaxially arranged with the second air inlet 8, and the third outlet 30 is connected to the fourth inlet through a connecting pipe 32. 31 communicates, and one end of the connecting pipe 32 connected to the fourth inlet 31 is in sealing connection with the second air inlet 8 . The refrigerant gas enters the inner cavity of the housing 2 through the first air inlet 1 , and after cooling the motor, enters the suction part of the pump chamber 7 through the third outlet 30 , the connecting pipe 32 and the second air inlet 8 .

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap