Full-automatic mass spectrum pretreatment system

A fully automatic mass spectrometry technology, applied in the field of fully automatic mass spectrometry pretreatment system, can solve the problems of long processing time, complicated operation, difficult to achieve high throughput, etc., and achieve the effect of strong automation ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

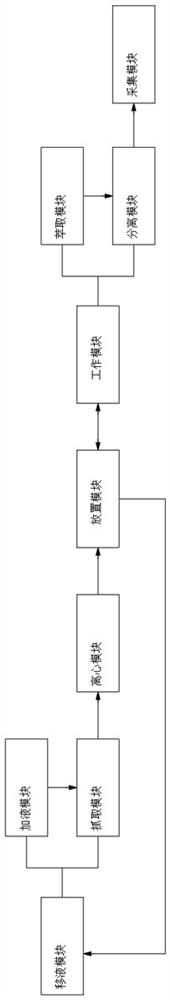

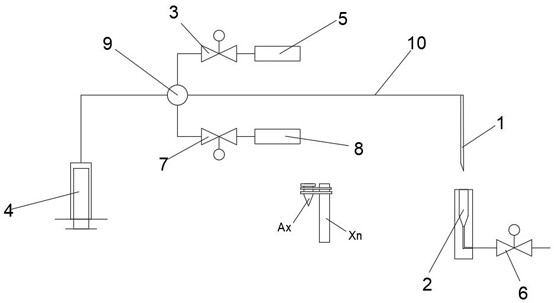

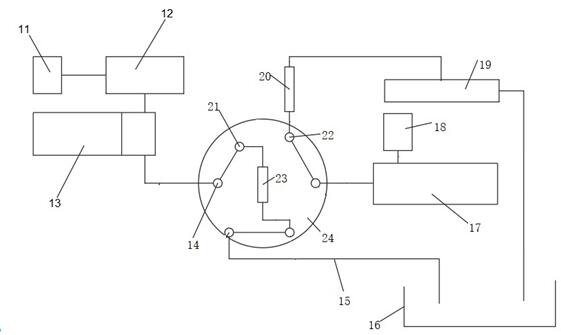

[0052] refer to Figure 1-3As shown, a fully automatic mass spectrometry pretreatment system includes a pipetting module, a centrifugal module, a placement module, a working module, and an acquisition module. The pipetting module is connected to the centrifugal module in one direction, and the centrifugal module is connected to the placement module in one direction. Two-way connection with the working module, two-way connection between the placement module and the pipetting module, one-way connection between the working module and the acquisition module;

[0053] The pipetting module is used to add samples and protein agents to the centrifuge tube and move the centrifuge tube to the centrifuge;

[0054] The centrifuge module is used to centrifuge the sample in the centrifuge tube;

[0055] The placement module is used to move the centrifuged sample placed in the centrifuge tube to the centrifuge tube rack together with the centrifuge tube;

[0056] The working module is used...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com