Novel transformer oil baffle plate structure suitable for special environment

A technology for oil baffles and transformers, applied in the field of transformers, can solve problems such as inability to meet high-efficiency production requirements, reduce transformer costs, etc., achieve the effects of reducing material and labor costs, saving material costs, and reducing the size of the axial oil passage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

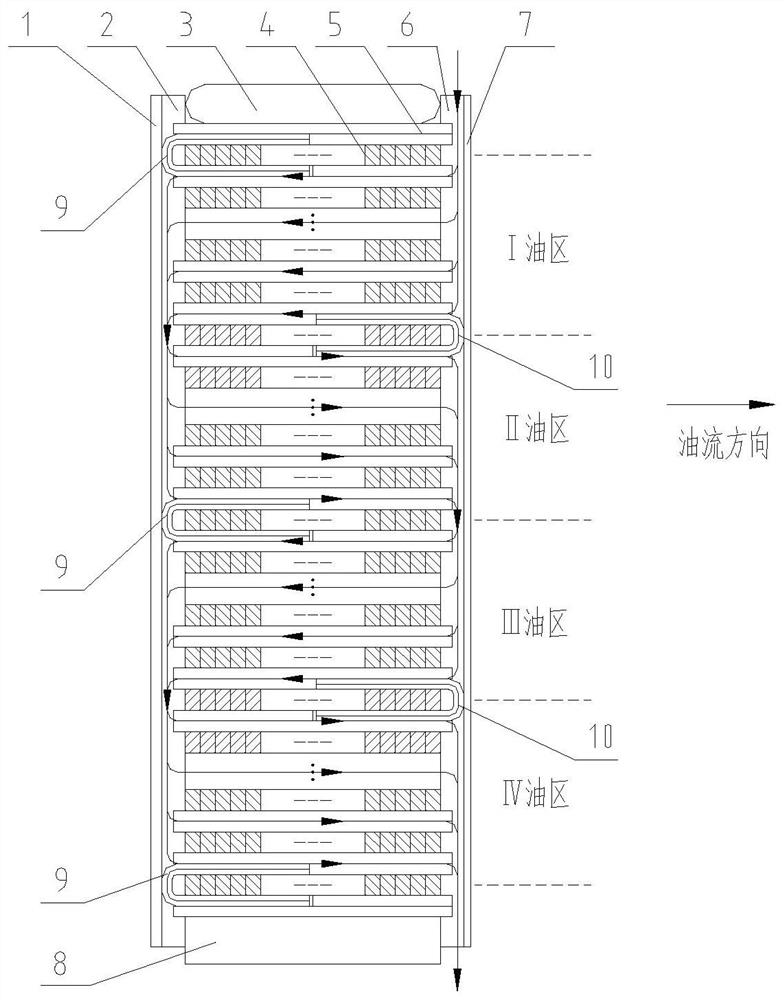

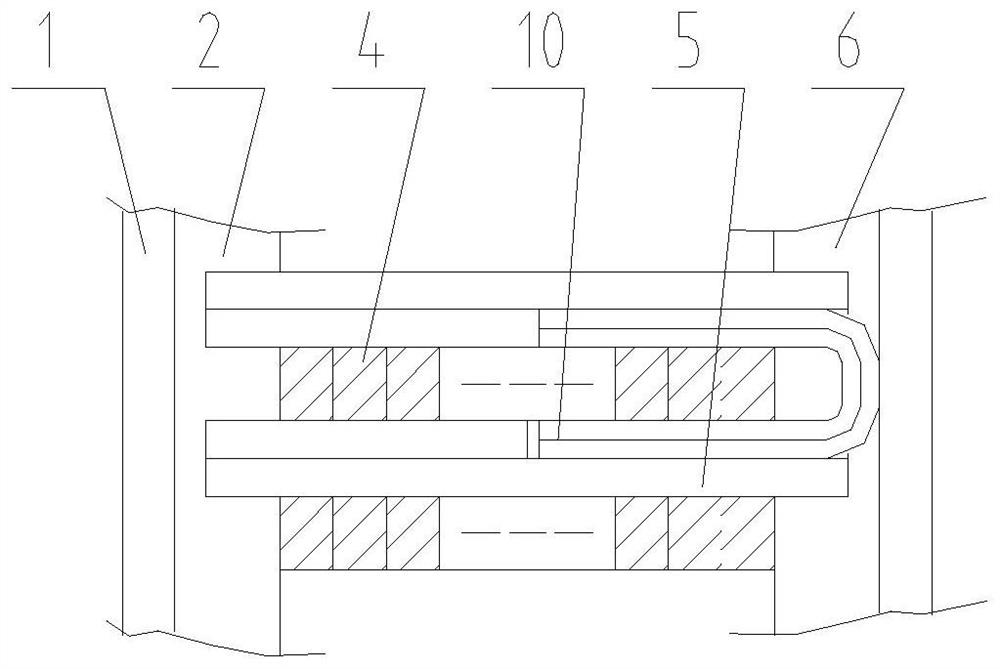

[0027] The specific embodiments provided by the present invention will be described in detail below in conjunction with the accompanying drawings.

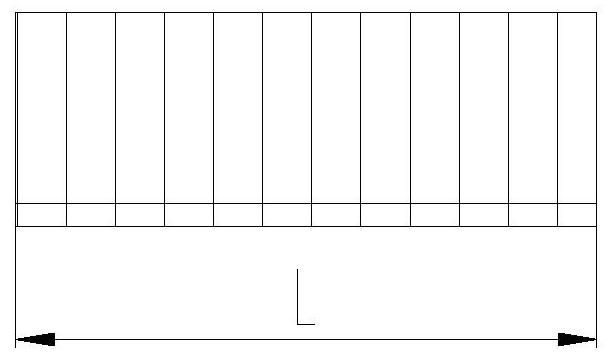

[0028] Such as Figure 1-6 As shown, a new transformer oil baffle structure suitable for special environments, the coil of the transformer is a wire cake 4 type structure, the oil baffle structure includes an inner oil baffle 9 and an outer oil baffle 10, The inner oil baffle 9 and the outer oil baffle 10 have the same structure, both of which are U-shaped annular structures folded from corrugated cardboard. The oil plate 10 is on the outside of the wire cake 4 (that is, away from the iron core side), and the U-shaped openings are all facing the wire cake 4 to clamp the wire cake 4.

[0029] Such as figure 1 As shown, the coil of the transformer is divided into multiple oil areas from top to bottom, each oil area includes a multi-layer wire cake 4, an inner oil baffle plate 9 is placed at the head and end of the coil, and the o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com