Chocolate-flavored fermented milk and preparation method thereof

A technology for fermented milk and chocolate, applied in dairy products, milk preparations, bottle filling and other directions, can solve the problems of high equipment investment cost and small application scope, and achieve the effect of reducing processing cost, improving application scope and ensuring accuracy.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0042] The raw material composition of the chocolate-flavored fermented milk in this Example is shown in the following table.

[0043] Table 1: Chocolate-flavored fermented milk (based on 1000kg ingredients)

[0044] serial number raw material quantity 1 raw milk 852.45kg 2 White sugar 75.2kg 3 starch 2.35kg 4 Yeast beta glucan 47g 5 Bifidobacterium BB-12 2.5g 6 Lactobacillus plantarum 1.665D 7 Strain JOINTEC D 3D (7.5U) 8 Chocolate Pops with Blueberry Zest 70kg

[0045] A method for preparing chocolate-flavored fermented milk, comprising the steps of:

[0046] Step 1: Weighing, calculate according to the formula ratio in Table 1 and accurately weigh each raw material for later use;

[0047] Step 2: Batching, inject 35-40% raw milk into the batching tank, heat up to 50-60°C through plate heat exchanger circulation, start the shearing machine, slowly disperse and add starch and sweetener mixture (s...

Embodiment 2

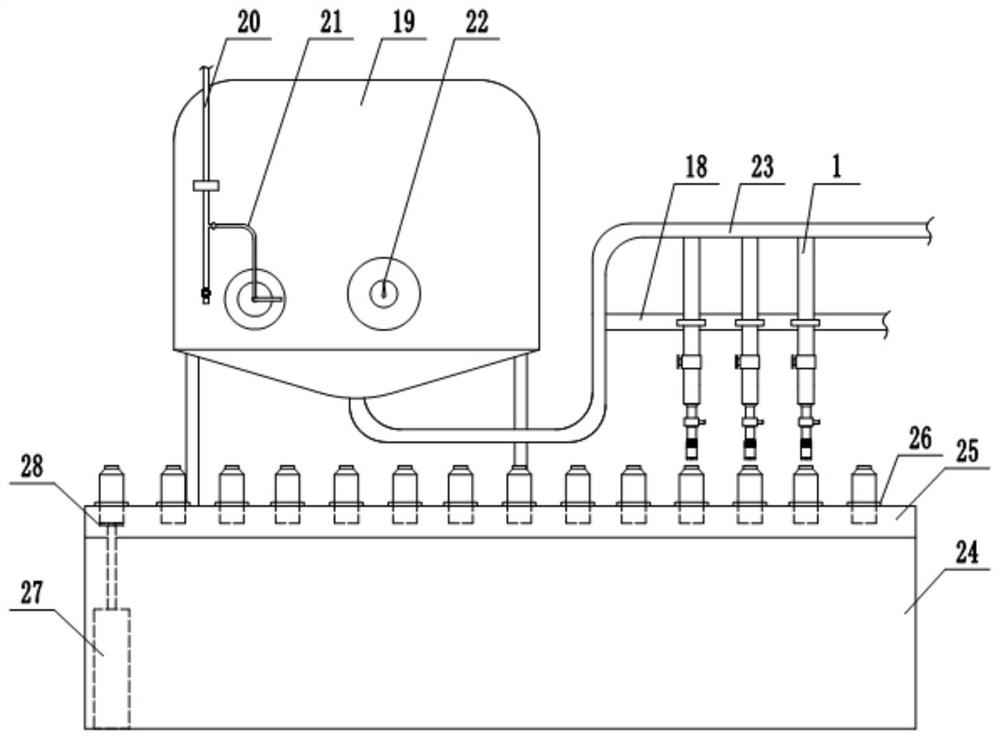

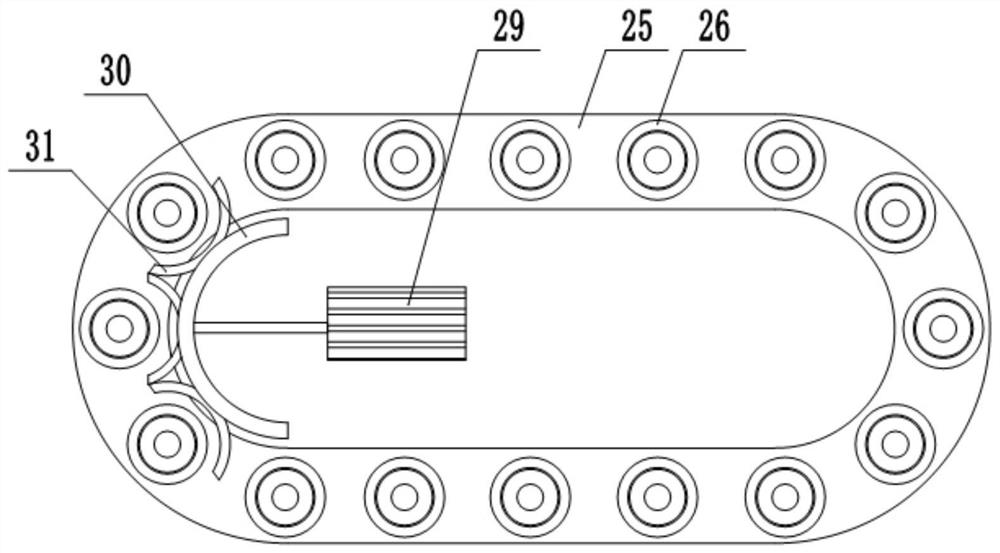

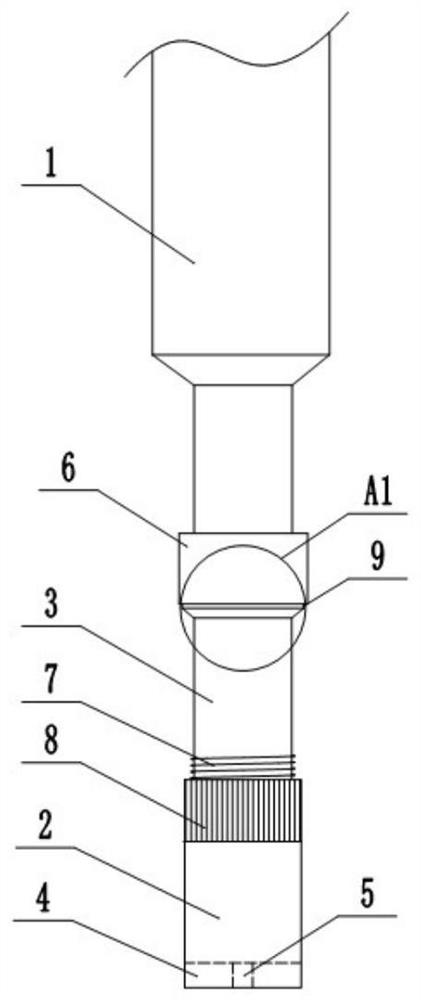

[0071] Such as Figure 7 , Figure 8 As shown, the difference between this embodiment and Embodiment 1 is that: the middle part of the buffer gasket 4 in this embodiment is provided with a concentric concave accommodation groove 17, the shape of the accommodation groove 17 is ring-shaped, and the milk inlet 5 is provided in the middle of the annular receiving groove 17.

[0072] Due to the fact that dairy products will have different product types in the actual production process, including pure dairy products and flavored dairy products with fruit pieces, etc. When filling pure dairy products, you can use the buffer gasket 4 with a smaller milk injection port 5; when filling flavored dairy products with fruit pieces, you need to use a larger buffer gasket 4 with milk injection port 5 . In this technical solution, by arranging the accommodation groove 17 on the buffer gasket 4, the buffer gasket 4 with a smaller milk injection port 5 can be placed in the accommodation groove ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Acidity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com