Device for continuously making solder electrolytic anode plate row sheets and manufacturing method

A technology of anode plate and solder, which is applied in the field of equipment for making solder electrolysis anode plate, can solve the problems of complex process and facilities, large floor area, and many production links, so as to reduce equipment investment, improve productivity, and product quality Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The content of the present invention will be further elaborated below in conjunction with the drawings and embodiments of the description.

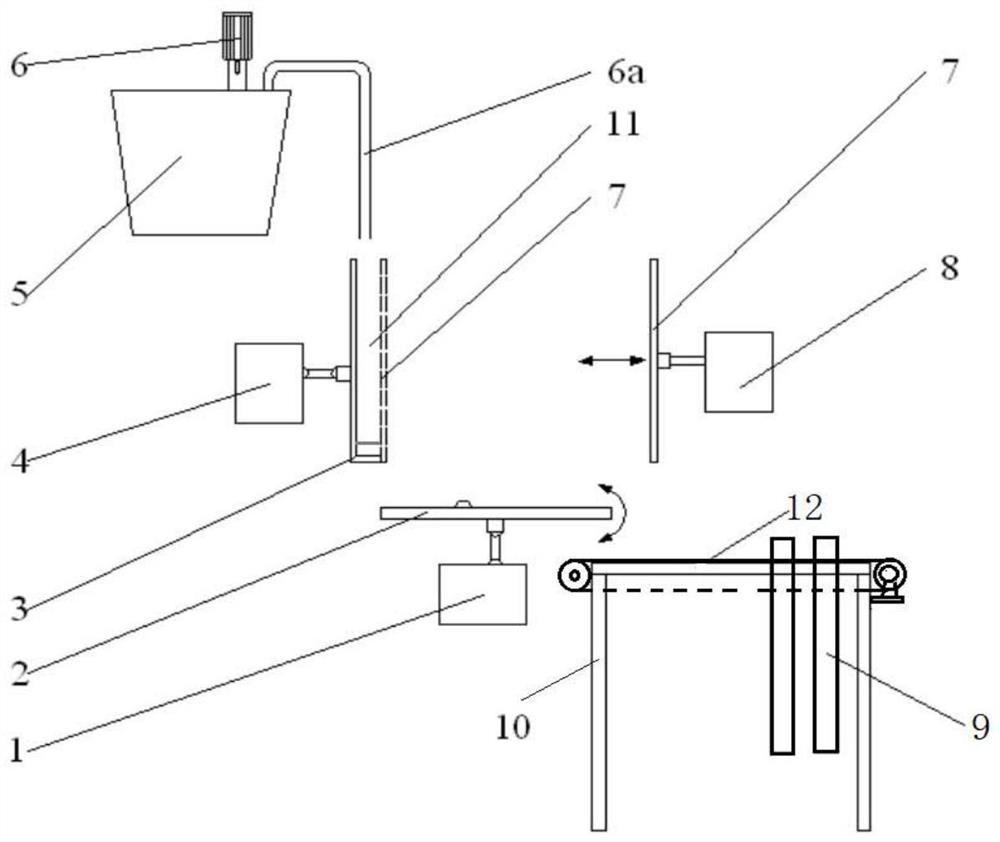

[0030] Such as figure 1 As shown, a device for continuously producing solder electrolysis anode plates, including a chemical pot 5, a liquid suction pump 6 installed on the top of the chemical pot, a pump tube 6a, a combined mold arranged under the liquid outlet end of the pump tube, and a set The anode sheet discharge receiving mechanism under the combined mould, and the anode sheet discharge mechanism 10 arranged under the anode sheet discharge receiving mechanism.

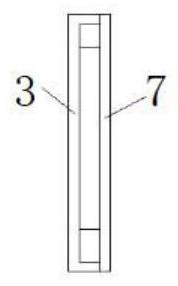

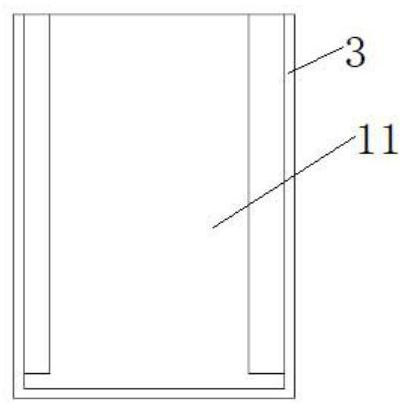

[0031] The combination mold is as figure 2 image 3 Shown is the vertical deep groove mold that forms the T-shaped plate-shaped inner cavity after being combined, is made up of the vertical rectangular box mold 3 of top and outside opening and the flat mold 7 that is positioned at the rectangular box mold outside. After the flat mold cover is closed on the outsid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com