A battery welder

A welding machine and battery technology, applied in welding equipment, auxiliary welding equipment, welding/cutting auxiliary equipment, etc., can solve the problems of heat accumulation, affecting the heat dissipation of electric welding machines, and easy circuit damage, and achieve the effect of reducing the possibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0045] The following is attached Figure 1-6 The application is described in further detail.

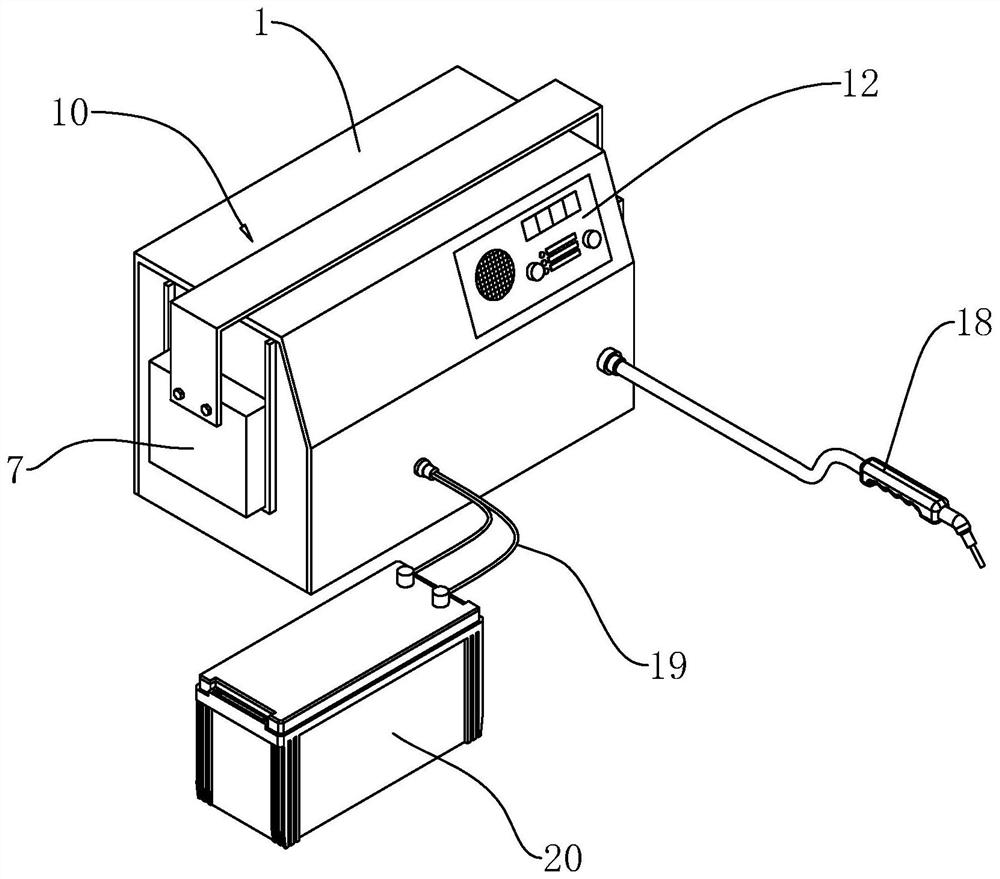

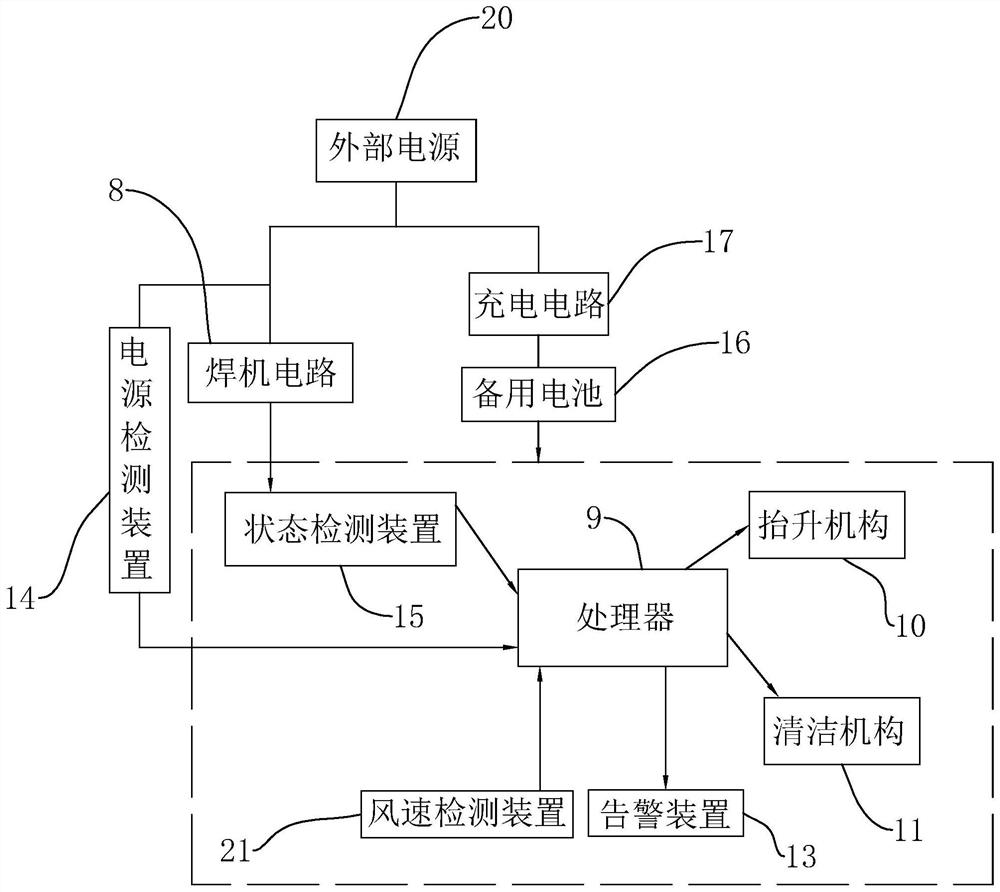

[0046] The embodiment of the present application discloses a battery welding machine, referring to figure 1 , figure 2 , including a housing 1, a welding machine circuit 8 installed in the housing 1, a welding torch 18 is connected to the output end of the welding machine circuit 8, a power line 19 is connected to the input end of the welding machine circuit 8, and the welding machine circuit 8 passes through The power line 19 is connected to an external power source 20 . The external power supply 20 may be a vehicle storage battery, or a self-contained storage battery. Both the external power supply 20 and the battery welder body are easy to carry, and are especially suitable for use in outdoor operations.

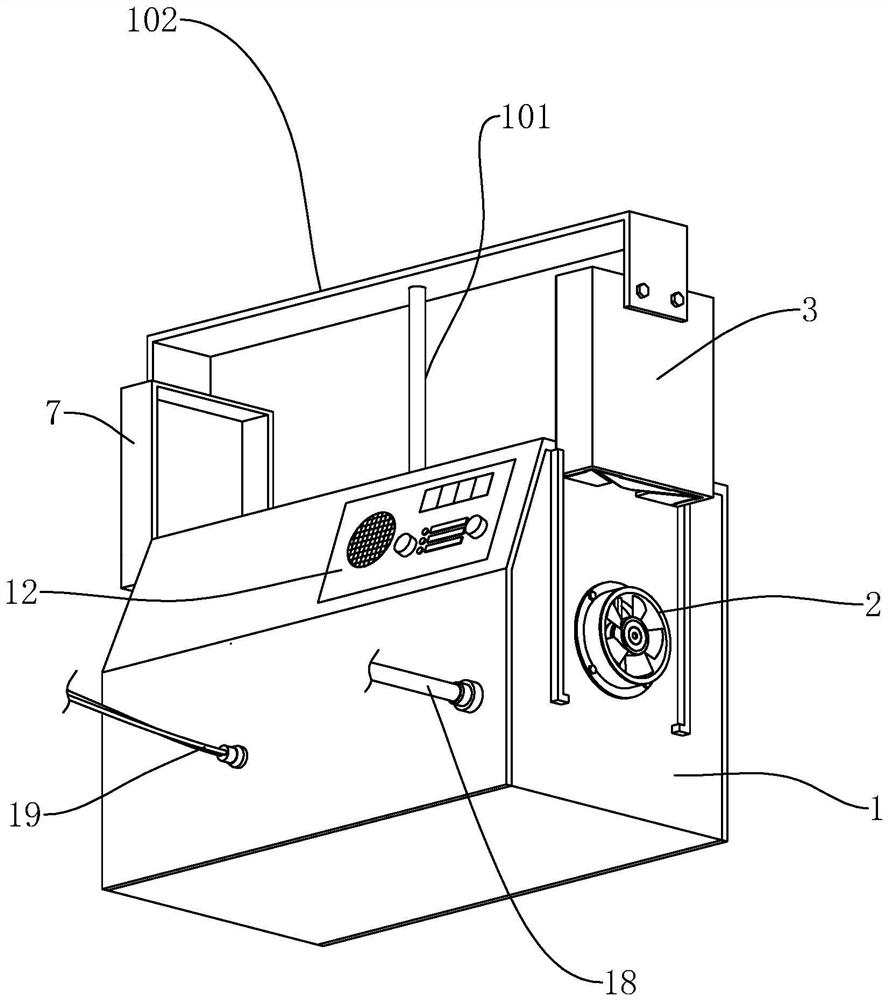

[0047] see image 3 , Figure 4 Two guide strips extending along the height direction of the housing 1 are fixed on both end surfaces of the housing 1 , and a slide groov...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com