production sio x device and method

A technology for collecting units and gases, applied in the direction of silicon oxide, etc., can solve the problems of cumbersome operation steps, high energy consumption, and low efficiency, and achieve the effects of improving product quality, reducing equipment investment, and reducing energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0049] This embodiment provides a method for producing SiO x devices, including:

[0050] The reaction unit is used to heat the added reaction raw materials silicon and / or carbon and silicon dioxide step by step, so that the low boiling point impurities in the raw materials are evaporated into gaseous impurities step by step, and the raw materials react to form gaseous SiO x , where 1

[0051] The gas discharge unit is connected with the reaction unit. The gas discharge unit includes: a gas discharge pipeline and a heating unit arranged on the gas discharge pipeline. The gas discharge unit is used to transport and heat the gaseous materials flowing out of the reaction unit keep it in gaseous state;

[0052] The collection unit is connected with the gas discharge unit, and the collection unit is used to receive the gaseous material flowing out from the gas discharge unit;

[0053] The temperature adjustment mechanism is set in the collection unit. The temperature adjust...

Embodiment 2

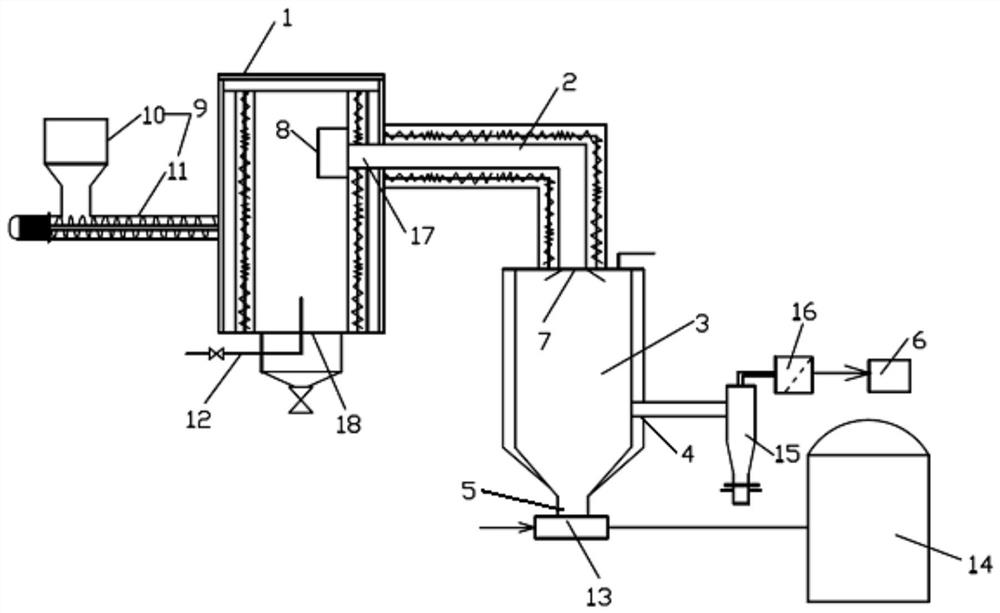

[0064] Such as figure 1 As shown, this embodiment provides a production SiO x devices, including:

[0065] Reaction unit 1 is used to heat the added reaction raw materials silicon and silicon dioxide step by step, so that the low boiling point impurities in the raw materials are evaporated into gaseous impurities step by step, and the raw materials react to form gaseous SiO x , wherein 1

[0066] The gas discharge unit 2 is connected with the reaction unit 1. The gas discharge unit 2 includes: a gas discharge pipeline and a heating unit arranged on the gas discharge pipeline. The material is conveyed and heated to keep it ...

Embodiment 3

[0104] This embodiment provides a method for producing SiO x The device, the difference with the device in embodiment 2 is:

[0105] The solid suction unit in this embodiment is a Venturi mechanism.

[0106] This embodiment provides a method of using the device in this embodiment to produce SiO x The method, the difference with the method in embodiment 2 is:

[0107] The raw materials in step 1) are C-containing materials and silicon dioxide, and the vacuum unit is started to evacuate to 100 Pa, and the C-containing materials are crushed to 50 meshes, and the SiO-containing materials are 2 The material is crushed to 50 mesh, press C: SiO 2 The molar ratio is 3:1 and the mixture is fully mixed and then granulated, and heated through the reaction unit at a heating temperature of 100°C.

[0108] In step 2), the heating of the gas discharge unit is controlled, and the heating temperature is 100°C.

[0109] In step 3), the heating of the collection unit is adjusted through the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| current efficiency | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com