Aqueous ink jet composition, method for producing aqueous ink jet composition, and method for producing recording

A water-based inkjet, manufacturing method technology, applied in the direction of copying/marking method, application, ink, etc., can solve the problems of recording medium type limitation, melting, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

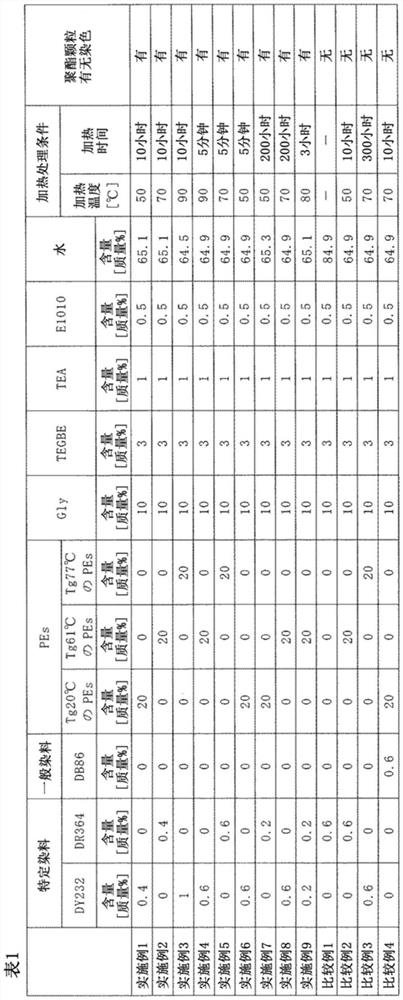

Embodiment 1

[0179] First, C.I. Disperse Yellow 232 as a specific dye, MD-1480 (manufactured by Toyobo Co., Ltd.) as an aqueous dispersion of self-emulsifying polyester having a glass transition temperature of 20°C, glycerin, and triethylene glycol monobutyl ether , triethanolamine, Olfine E1010 (manufactured by Nissin Chemical Industry Co., Ltd.) as a surfactant, and pure water were mixed at a predetermined ratio, and stirred at a speed of 3000 rpm by a high-speed dispersion mixer (manufactured by Silverson Co., Ltd.) to form a slurry.

[0180] Next, the produced slurry and glass beads with a diameter of 0.5 mm were stirred and dispersed under water cooling using a bead mill (LMZ015, Ashizawa Finetech Ltd.).

[0181] Thereafter, the glass beads were removed, and heat treatment was performed at 50° C. for 10 hours. Accordingly, an inkjet ink was obtained as an aqueous inkjet composition containing polyester particles dyed with a dye.

[0182] In addition, the polyester contained in MD-148...

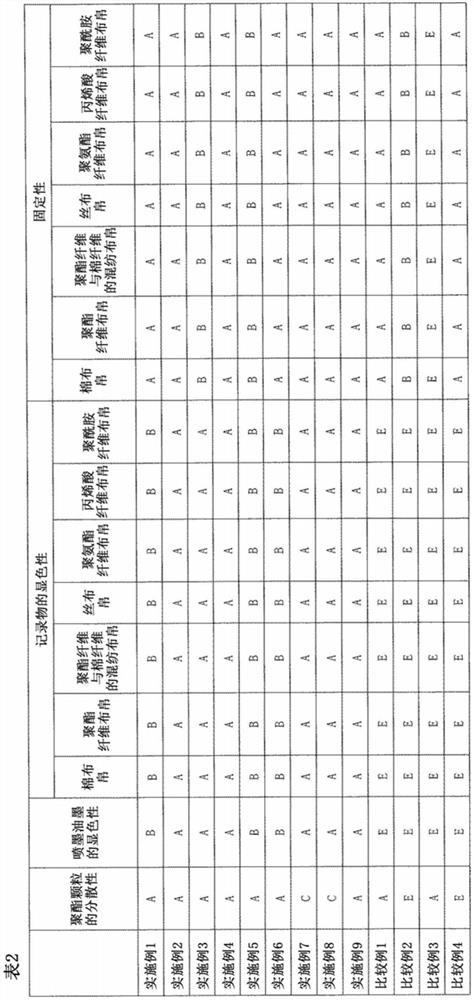

Embodiment 2~9

[0184] The type of specific dye, the type of polyester, and the ratio of each component were adjusted to achieve the composition shown in Table 1, and the conditions of the heat treatment were set as shown in Table 1, except that it was produced in the same manner as in Example 1 above. inkjet ink.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com